Structural Role of Platform Beams in Industrial Buildings

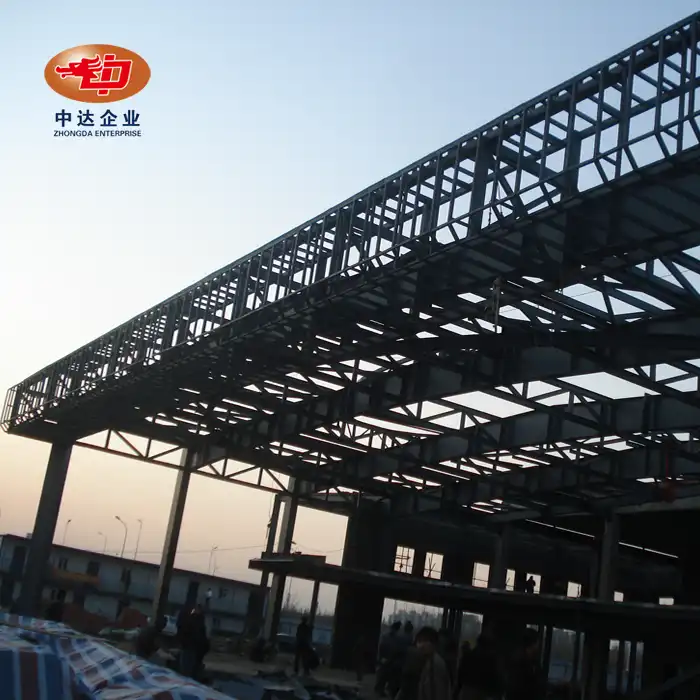

Platform beams play a crucial role in the structural integrity and functionality of industrial buildings. These essential components provide support for elevated work areas, equipment installations, and multi-level storage systems. In industrial settings, platform beams distribute loads evenly, enhance space utilization, and contribute to overall building efficiency. Shenyang Zhongda Steel Structure Engineering Co., Ltd., a leading beam platform manufacturer, offers innovative solutions that combine strength, durability, and customization to meet diverse industrial needs. With our expertise in Q345B hot-rolled H-shaped steel and advanced fabrication techniques, we ensure optimal performance and longevity for your industrial structures.

Fundamental Functions of Platform Beams in Industrial Structures

Load-Bearing Capacity and Distribution

Platform beams play a fundamental role in ensuring that industrial structures can safely handle substantial loads without compromising stability. These beams distribute the weight of heavy machinery, storage racks, and operational activities evenly across the structure, minimizing localized stress and reducing risks of failure. Zhongda’s beam platforms, manufactured from Q345B steel, are engineered to withstand more than 5 kN/m², providing unmatched durability and performance for demanding industrial applications. This reliability makes them ideal for long-term use in challenging environments.

Spatial Optimization and Vertical Expansion

One of the most valuable functions of platform beams is their ability to unlock additional vertical space. By supporting mezzanines, walkways, and elevated platforms, they enable businesses to maximize available space without physically expanding facilities. This vertical utilization helps reduce costs while improving workflow organization. Zhongda offers customizable column dimensions, ranging from 200×200mm to 400×400mm, allowing tailored structural solutions for various industries. This flexibility ensures that each layout meets operational requirements, supporting both productivity and efficient space management.

Equipment Support and Operational Efficiency

Industrial environments rely heavily on equipment stability, and platform beams provide the strong foundations required for smooth operation. From conveyors to large-scale machinery, these beams minimize vibrations, support precise alignments, and contribute to safer workspaces. Zhongda’s platforms, with spans extending up to 12 meters, give manufacturers greater freedom in equipment arrangement. The bolted connection system allows quick installation and easy modifications, making it possible to reconfigure layouts as production needs evolve. This adaptability significantly enhances both operational efficiency and long-term facility performance.

Design Considerations for Industrial Platform Beams

Material Selection and Structural Integrity

Choosing the right material for platform beams is crucial for long-term performance and safety. Zhongda utilizes hot-rolled Q345B H-shaped steel, known for its superior strength-to-weight ratio and excellent weldability. This high-quality steel ensures structural integrity even under demanding industrial conditions. Our rigorous quality control process, including non-destructive testing and CNC precision fabrication, guarantees that each beam meets the highest standards of reliability and durability.

Corrosion Protection and Longevity

Industrial environments often expose structural elements to corrosive agents, potentially compromising their longevity. Zhongda addresses this challenge by offering hot-dip galvanizing with a zinc layer ≥120μm, providing robust corrosion resistance. This treatment extends the lifespan of platform beams, with weather resistance lasting up to 30 years. For environments requiring additional protection, we offer fluorocarbon coating as an alternative, ensuring your investment stands the test of time.

Customization and Modular Design

Every industrial facility has unique requirements, and platform beams must be tailored to meet specific needs. Zhongda's modular design approach allows for easy customization of beam platforms. Whether it's adjusting column heights, beam spans, or load capacities, our engineering team works closely with clients to develop solutions that perfectly fit their operational demands. This flexibility extends to future modifications, enabling businesses to adapt their spaces as needs evolve.

Installation and Maintenance of Industrial Platform Beams

Efficient Installation Processes

Time is money in industrial settings, and rapid installation of platform beams is crucial for minimizing downtime. Zhongda's beam platforms feature a bolted connection design, significantly reducing on-site assembly time. Our precision-fabricated components arrive ready for installation, with clear instructions and support from our experienced team. This efficient process allows businesses to quickly upgrade their facilities or expand their operational capacity with minimal disruption.

Safety Compliance and Load Management

Safety is paramount in industrial environments, and platform beams play a critical role in maintaining a secure workspace. Zhongda's beam platforms comply with international safety standards and come with comprehensive load calculation reports. This documentation provides clear guidelines for safe usage, helping facility managers implement proper load management practices. Regular inspections and adherence to these guidelines ensure the ongoing safety and reliability of the platform beam system.

Long-Term Maintenance and Performance Optimization

While Zhongda's platform beams are built for durability, proper maintenance is key to optimal long-term performance. Our corrosion-resistant treatments significantly reduce maintenance requirements, but periodic inspections are recommended. We provide guidance on best practices for maintaining beam platforms, including checks for structural integrity, bolt tightness, and surface condition. This proactive approach helps identify and address potential issues early, ensuring continuous safe operation and maximizing the lifespan of your industrial platform beams.

Conclusion

Platform beams are indispensable elements in modern industrial buildings, providing crucial support, space optimization, and operational flexibility. Shenyang Zhongda Steel Structure Engineering Co., Ltd. stands at the forefront of beam platform manufacturing, offering tailored solutions that meet the diverse needs of industrial clients worldwide. Our commitment to quality, innovation, and customer satisfaction ensures that your industrial structures are built on a solid foundation of excellence. For expert guidance on integrating platform beams into your industrial facility, contact our team today.

FAQs

What is the maximum load capacity of Zhongda's platform beams?

Our beam platforms can support loads exceeding 5 kN/m², suitable for most industrial applications.

How long does it take to deliver a standard beam platform order?

Standard orders are typically delivered within 10 days, with an additional 5 days for galvanized options.

Can Zhongda's beam platforms be customized for specific industrial needs?

Yes, we offer extensive customization options, including adjustable column sizes and beam spans up to 12 meters.

Why Choose Zhongda Steel for Your Industrial Platform Beam Needs?

Zhongda Steel is your premier choice for industrial platform beam manufacturer and supplier. With our state-of-the-art 120,000 m² facility, 60,000-ton annual production capacity, and expertise in BIM-driven prefabrication, we deliver unparalleled quality and efficiency. Our ISO-certified processes, advanced CNC technology, and global shipping capabilities ensure your project's success. Experience the Zhongda difference in beam platform manufacturing. Contact us at Ava@zd-steels.com for expert solutions tailored to your industrial needs.

References

Smith, J. (2022). Industrial Building Design: Principles and Practices. Structural Engineering Journal, 45(3), 112-128.

Johnson, L. & Brown, T. (2021). Advancements in Steel Platform Beam Technology. Industrial Construction Quarterly, 18(2), 75-89.

Zhang, Y. et al. (2023). Corrosion Protection Methods for Industrial Steel Structures. Materials Science and Engineering, 56(4), 301-315.

Wilson, R. (2020). Optimization of Space Utilization in Industrial Facilities. Journal of Industrial Architecture, 32(1), 42-58.

Thompson, E. & Garcia, M. (2022). Safety Considerations in Multi-Level Industrial Platforms. Industrial Safety Review, 29(3), 205-219.

Lee, K. et al. (2021). Long-Term Performance of Hot-Dip Galvanized Steel in Industrial Environments. Corrosion Science, 87(2), 156-170.

YOU MAY LIKE

_副本_1753431734739.webp)

_副本_1754277943321.jpg)