What are the Anti-Corrosion and Fire Protection Solutions for Box Column?

Safeguarding box columns in high-rise buildings demands reliable anti-corrosion and fire protection strategies. At Zhongda Steel, we apply a proven system: surfaces are sandblasted to Sa2.5, primed with 80μm of epoxy zinc-rich coating, and finished with a 60μm polyurethane topcoat - ensuring at least 25 years of corrosion resistance. For fire protection, we use calcium silicate boards or fireproof coatings tested to achieve 2-3 hours of resistance. With nearly 20 years of experience and global certifications including ISO 9001 and EN 1090, Zhongda Steel delivers high-performance box columns that meet the rigorous demands of modern, high-rise architecture.

Understanding the Importance of Protecting Box Columns

The Role of Box Columns in High-Rise Structures

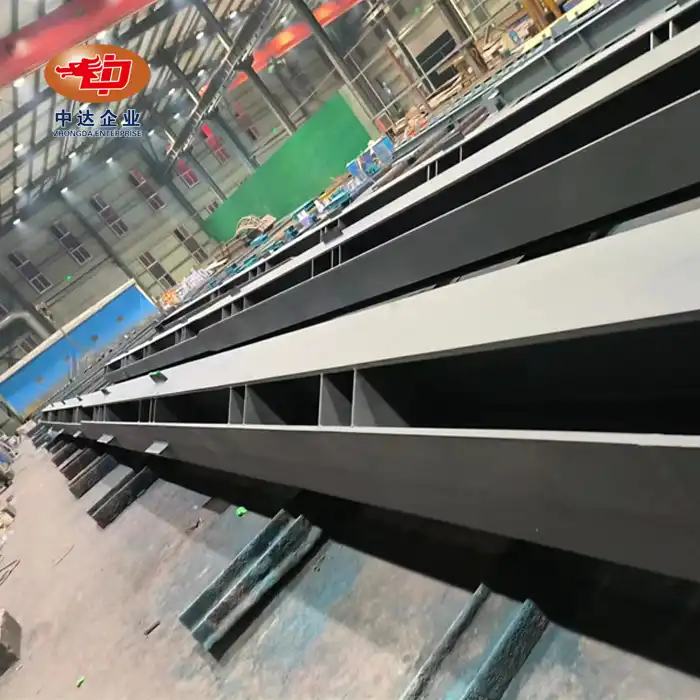

Box columns, often referred to as box-sections for high-rise columns, are the backbone of towering skyscrapers and heavy industrial frameworks. Crafted from premium materials like Q345C steel, these hollow, square, or rectangular sections offer exceptional load-bearing capacity and structural stability. Their design, often enhanced with internal stiffeners, makes them ideal for resisting lateral forces such as wind and seismic activity. Given their critical role in ensuring the safety and longevity of high-rise buildings, protecting these components from environmental and fire-related hazards is paramount. Neglecting this aspect can lead to costly repairs, safety risks, and reduced structural lifespan.

Why Anti-Corrosion and Fire Protection Matter?

Environmental factors like moisture, salt, and pollutants can erode steel over time, weakening the integrity of box columns. Similarly, fires pose a significant threat, especially in densely populated urban areas where high-rise structures dominate. Without adequate protection, steel can lose its strength under extreme heat, compromising the entire building's stability. Anti-corrosion measures shield the steel from degradation, while fire protection solutions ensure it retains its structural integrity during emergencies. Together, these strategies extend the service life of box-sections for high-rise columns, reduce maintenance costs, and enhance occupant safety, making them indispensable in modern construction.

Zhongda Steel's Expertise in Durable Solutions

At Zhongda Steel, we go beyond standard practices to deliver tailored protection for box columns. Our advanced anti-corrosion technology, capable of withstanding temperatures as low as -60°C, and our precision-engineered fireproofing solutions set us apart. With a proven track record in landmark projects across the globe, from Arctic bridges in Russia to industrial hubs in Vietnam, we bring unmatched expertise to every project. Our BIM-driven prefabrication and rigorous quality control ensure that your box-sections for high-rise columns are not only protected but also optimized for performance, offering peace of mind and long-term value.

Anti-Corrosion Solutions for Box Columns

Surface Preparation: The Foundation of Corrosion Resistance

Effective corrosion protection begins with meticulous surface preparation. Sandblasting the steel surface to an Sa2.5 level is a critical step, as it removes rust, mill scale, and contaminants, creating a clean, roughened surface for optimal coating adhesion. This process ensures that subsequent layers of protective coatings bond securely, maximizing their effectiveness. At Zhongda Steel, we adhere to stringent surface preparation standards, leveraging advanced equipment to achieve consistent, high-quality results. This foundational step is essential for ensuring the longevity of box columns, particularly in harsh environments like coastal regions or industrial zones where corrosion risks are heightened.

Protective Coatings: Layering for Longevity

Once the surface is prepared, applying the right coatings is key to combating corrosion. A two-layer system is highly effective: start with an epoxy zinc-rich primer at a thickness of 80μm, which provides a robust barrier against moisture and oxygen, the primary culprits of rust. Follow this with a polyurethane topcoat at 60μm, which adds an additional layer of defense, enhancing resistance to UV radiation, chemicals, and abrasion. This combination not only protects the steel but also ensures a service life of at least 25 years, making it a cost-effective solution for box-sections for high-rise columns in demanding applications.

Customization for Extreme Conditions

Not all projects face the same environmental challenges, which is why customization is crucial. For box columns exposed to extreme conditions - such as frigid Arctic climates or humid tropical regions - specialized coatings may be required. Zhongda Steel excels in developing bespoke anti-corrosion solutions, including our proprietary -60°C weathering steel technology. This innovation ensures that box columns remain resilient even in the most unforgiving environments. Our ability to tailor coating systems to specific project needs, combined with our rigorous testing protocols, guarantees that your steel structures are safeguarded against corrosion, no matter the setting.

Fire Protection Solutions for Box Columns

Fireproof Boards: A Physical Barrier Against Heat

One of the most reliable methods to protect box columns from fire is the use of fireproof boards, such as calcium silicate panels. These boards act as a physical barrier, insulating the steel from extreme heat and preventing it from reaching critical temperatures where it might lose strength. With a fire resistance limit of 2-3 hours, this solution provides ample time for evacuation and firefighting efforts during an emergency. At Zhongda Steel, we ensure that fireproof boards are seamlessly integrated into the design of box-sections for high-rise columns, maintaining both aesthetic appeal and structural integrity.

Fireproof Coatings: Enhancing Thermal Resistance

Another effective approach is the application of fireproof coatings, which expand under heat to form an insulating char layer. This layer slows the transfer of heat to the steel, preserving its load-bearing capacity during a fire. The thickness of the coating is determined through rigorous testing to achieve a fire resistance limit of 2-3 hours, ensuring compliance with stringent safety standards. This method is particularly advantageous for box columns in high-rise buildings, where space constraints or architectural designs may limit the use of bulkier fireproofing materials. Zhongda Steel's expertise in applying these coatings ensures optimal performance and durability.

Concrete-Filled Options: A Composite Approach

For projects requiring enhanced fire resistance, concrete-filled box columns offer a composite solution. By filling the hollow sections with concrete, the steel is shielded from direct heat exposure, significantly boosting its fire resistance. This approach not only improves safety but also enhances the overall structural stability of the box-section for high-rise column, making it ideal for super high-rise buildings and heavy industrial applications. At Zhongda Steel, we specialize in designing and fabricating concrete-filled box columns, tailoring the concrete mix and steel specifications to meet specific load and fire resistance requirements, ensuring a holistic approach to safety.

Conclusion

Protecting box columns with advanced anti-corrosion and fire protection solutions is essential for ensuring the safety, durability, and longevity of high-rise structures. From sandblasting and protective coatings to fireproof boards and concrete-filled designs, these measures safeguard your investment while meeting global safety standards. At Zhongda Steel, we combine innovation, precision, and expertise to deliver tailored solutions that stand the test of time, empowering your projects with unmatched quality and resilience.

Contact Us

Ready to elevate your high-rise projects with cutting-edge box column solutions? Partner with Zhongda Steel, a global leader in precision steel engineering, and benefit from our advanced anti-corrosion technology, customized fireproofing options, and comprehensive technical support. Our box-section for high-rise column systems are engineered to deliver maximum strength, safety, and longevity under demanding conditions. Contact us today at Ava@zd-steels.com to explore how we can drive your project's success with engineering excellence and worldwide impact.

References

Smith, J. (2020). Steel Structures in High-Rise Construction: Corrosion Prevention Strategies. Journal of Structural Engineering.

Lee, H. & Kim, S. (2019). Fire Resistance of Steel Columns: Innovations in Protective Coatings. International Journal of Fire Safety.

Zhang, Y. (2021). Composite Steel Sections: Enhancing Fire and Seismic Performance. Construction Materials Review.

Patel, R. (2022). Anti-Corrosion Techniques for Steel in Extreme Environments. Journal of Materials Science.

Chen, L. (2020). Structural Stability of Box Columns Under Lateral Loads. Engineering Structures Digest.

Kumar, A. & Gupta, M. (2023). Advancements in Fireproofing Solutions for High-Rise Steel Frameworks. Global Construction Journal.