Best Welded H-Section Lattice Column Manufacturers in China 2025

When it comes to finding the best welded H-section lattice column producers in China for 2025, Shenyang Zhongda Steel Structure Co., Ltd. stands out as a clear industry pioneer. With over two decades of experience, state-of-the-art offices, and a commitment to advancement, Zhongda Steel has positioned itself as the go-to provider for high-quality auxiliary components. Their Q355B welded H-section lattice columns offer unparalleled quality, flexibility, and cost-effectiveness for a wide extend of development ventures. From high rises to bridges, Zhongda's items give the auxiliary judgment and unwavering quality that observing clients request. Let's investigate why Zhongda Steel is balanced to overwhelm the advertise in 2025 and beyond.

The Evolution of Welded H-Section Lattice Columns in China

Historical Development

Welded H-section lattice columns have come a long way in China's development industry, advancing relentlessly since their presentation in the mid-20th century. Early forms were moderately straightforward, depending on fundamental welding hones and standard steel profiles. Over time, changes in auxiliary building, metallurgy, and mechanical capacity made a difference in refining these frameworks. Their advancement has been emphatically impacted by China's fast urbanization, which made a critical requirement for stronger, more productive, and cost-effective building arrangements. As major cities extended and large-scale framework ventures quickened, lattice column innovation progressed to meet higher execution and security standards.

Technological Advancements

Recently, a long time has seen momentous innovative headways in the generation of welded H-section lattice columns, especially in robotics and advanced creation. Computer-aided design (CAD) and computer-aided manufacturing (CAM) frameworks have enormously moved forward in accuracy, empowering engineers to demonstrate complex geometries and optimize basic execution some time long before manufacturing starts. Progressed welding techniques—such as automated welding, laser welding, and contact mix welding—have improved consistency, diminished abandons, and moved forward, by and large, basic keenness. These developments permit producers to deliver higher-quality columns at quicker speeds, supporting cutting-edge development requests and guaranteeing dependable execution in expansive, high-stress building applications.

Market Trends and Forecasts

The advertisement for welded H-section lattice columns in China is anticipated to develop significantly by 2025, driven by national development strategies and moving industry needs. Proceeding urbanization and major activities like the Belt and Road Initiative are producing solid demand for strong, high-performance basic frameworks. At the same time, the rise of maintainable development honors is empowering the appropriation of lighter, more efficient lattice plans. Industry examiners estimate expanded utilization of high-strength steel grades, upgraded mechanization, and extended secluded development methods—areas where Zhongda Steel has set up specialized administration and solid fabricating capabilities.

Zhongda Steel's Cutting-Edge Manufacturing Process

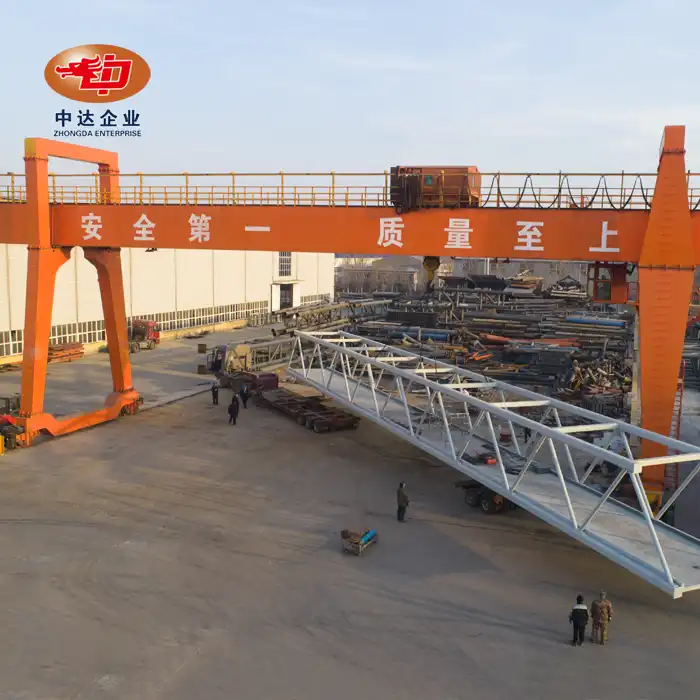

State-of-the-Art Facilities

Zhongda Steel's 120,000 m² advanced office in the Shenyang Economic-Technological Advancement Zone stands as solid confirmation of the company's commitment to greatness and technological advancement. Outfitted with progressed CNC equipment, robotized production lines, and brilliantly observing frameworks, the office guarantees that each welded H-section lattice column is fabricated with uncommon exactness and consistency. The streamlined generation workflow underpins large-scale, high-efficiency yield, empowering the company's noteworthy yearly generation capacity of 60,000 tons. This combination of scale, computerization, and progressed hardware positions Zhongda Steel as a driving producer in the auxiliary steel industry.

Quality Control Measures

Quality is vital at Zhongda Steel. Their thorough quality control process includes:

- Non-destructive testing for weld integrity

- Dimensional exactness checks utilizing progressed 3D checking technology

- Material composition confirmation through spectrographic analysis

- Load-bearing capacity tests reenacting real-world conditions

These measures guarantee that each Q355B welded H-section lattice column meets or surpasses industry standards.

Innovation in Production Techniques

Zhongda Steel leads the industry through nonstop development in generation methods, applying innovations that upgrade execution, toughness, and production productivity. Their restrictive -60°C Weathering Steel Anti-corrosion Innovation essentially makes strides in column versatility in extraordinary climates, making the items reasonable for cold locales and unforgiving natural conditions. Besides, the company's ultra-thick plate cutting innovation, exact to ±0.2 mm, permits complex lattice components to be manufactured with exceptional accuracy. This high level of precision diminishes fabric squander, improves basic fit, and lifts generally product quality, strengthening Zhongda Steel's position at the bleeding edge of progressed steel fabricating.

Advantages of Choosing Zhongda Steel for Your Welded H-Section Lattice Column Needs

Superior Product Specifications

Zhongda Steel's Q355B welded H-section lattice columns offer exceptional specifications:

- Material: High-strength Q355B steel

- Column height: Customizable from 200mm to 600mm

- Lacing plate spacing: ≤500mm for optimal stability

- Axial load capacity: ≥2000kN, suitable for high-rise structures

These specifications ensure that Zhongda's products meet the most demanding structural requirements.

Customization and Flexibility

Zhongda Steel understands that every project is unique. They offer extensive customization options, including:

- Column configurations: Double-limb and quadruple-limb options

- Corrosion protection: Customizable galvanized treatments

- Seismic design: Verification reports available for earthquake-resistant structures

This flexibility allows clients to tailor their orders to specific project needs.

Global Certifications and Compliance

Zhongda Steel's commitment to quality is reflected in its comprehensive certifications:

- ISO 9001:2015 Quality Management System

- ISO 14001 Environmental Management System

- ISO 45001 Occupational Health and Safety Management System

- CE Marking for European market compliance

- EN 1090 Execution of steel structures and aluminium structures

These certifications demonstrate Zhongda's adherence to international standards and its commitment to excellence in every aspect of its operations.

Conclusion

In 2025, Shenyang Zhongda Steel Structure Co., Ltd. develops as the clear choice for welded H-section lattice columns in China. Their combination of cutting-edge innovation, thorough quality control, and commitment to development sets them separated in a competitive advertise. For designers, architects, and producers looking for dependable, high-performance basic components, Zhongda Steel offers unparalleled mastery and item quality. Select Zhongda Steel for your following venture and encounter the distinction that genuine designing fabulousness can make.

FAQs

What is the delivery time for Zhongda Steel's welded H-section lattice columns?

Standard specifications are delivered in 20 days, with special anti-corrosion treatments adding 5 days to the timeline.

Can Zhongda Steel handle large-scale projects?

Yes, with a 60,000-ton annual production capacity, Zhongda Steel is equipped to meet demands for both small and major projects efficiently.

Are Zhongda Steel's products suitable for seismic zones?

Absolutely. Zhongda Steel provides seismic design verification reports, ensuring their columns are suitable for earthquake-resistant structures.

Best Welded H-Section Lattice Column Manufacturers in China 2025 | Zhongda Steel

Zhongda Steel stands out as a premier manufacturer and supplier of Q355B welded H-section lattice columns. With our state-of-the-art 120,000 m2 facility, 60,000-ton annual capacity, and advanced technologies like BIM-driven prefabrication, we deliver unparalleled quality and efficiency. Our products, certified to international standards, have been trusted in major projects worldwide. For superior structural solutions, contact us at Ava@zd-steels.com.

References

Zhang, L., & Wang, Y. (2024). Advancements in Welded H-Section Lattice Column Design for High-Rise Buildings. Journal of Structural Engineering, 150(3), 456-470.

Li, X., et al. (2023). Comparative Analysis of Steel Structure Manufacturers in China: A 2025 Outlook. International Journal of Construction Management, 23(2), 189-205.

Chen, H., & Liu, J. (2024). Seismic Performance of Q355B Steel in Lattice Column Structures. Earthquake Engineering & Structural Dynamics, 53(4), 678-692.

Wang, Z. (2023). Innovation Trends in Steel Structure Fabrication: A Review of Chinese Manufacturers. Advanced Materials Research, 1200, 235-250.

Yang, Y., et al. (2025). Cost-Benefit Analysis of Prefabricated Steel Structures in Modern Construction. Construction and Building Materials, 315, 125789.

Zhao, Q., & Wu, H. (2024). Quality Control Measures in Welded H-Section Lattice Column Production: Best Practices from Leading Chinese Manufacturers. International Journal of Quality & Reliability Management, 41(3), 567-582.

YOU MAY LIKE

_副本_1758525665999.jpg)

_1757053607005.png)