Preparing for Space Frame Roof Installation

Site Assessment and Planning

Before the installation process begins, a thorough site assessment is crucial. This involves evaluating the ground conditions, existing structures, and access points for equipment and materials. Engineers will review the soil bearing capacity to ensure it can support the weight of the space frame roof. They'll also consider factors like wind loads, snow loads, and seismic activity that could affect the roof's performance.

Once the assessment is complete, a detailed installation plan is developed. This plan outlines the sequence of activities, equipment requirements, and safety protocols. It also includes a timeline for each phase of the installation, helping to coordinate the various teams involved in the project.

Material and Equipment Preparation

Space frame roof components are typically prefabricated off-site to ensure precision and quality control. These components, including nodes, struts, and cladding materials, are then transported to the construction site. It's essential to have a well-organized staging area where these materials can be stored safely and accessed easily during installation.

The installation process requires specialized equipment, such as cranes, lifting gear, and scaffolding. This equipment must be inspected and certified before use to ensure safety and efficiency. Additionally, any necessary permits for equipment operation should be obtained well in advance of the installation date.

Safety Measures and Training

Safety is paramount in any construction project, and space frame roof installation is no exception. Before work begins, all personnel should receive comprehensive safety training specific to the project. This training covers topics such as fall protection, proper use of personal protective equipment (PPE), and emergency procedures.

A site-specific safety plan should be developed and communicated to all workers. This plan identifies potential hazards and outlines mitigation strategies. Regular safety meetings and inspections throughout the installation process help maintain a culture of safety and ensure compliance with all relevant regulations.

The Installation Process: Step-by-Step Guide

Foundation and Support Structure Preparation

The first step in the installation process is preparing the foundation and support structure. This may involve pouring concrete footings or installing steel columns, depending on the design specifications. The support structure must be precisely aligned and leveled to ensure the space frame roof sits correctly and performs as intended.

Once the support structure is in place, it's thoroughly inspected to verify its stability and accuracy. Any discrepancies are addressed before proceeding to the next phase of installation. This attention to detail at the foundation level is critical for the overall success of the project.

Assembly of Space Frame Components

With the foundation ready, the assembly of the space frame roof components begins. This process typically starts at ground level, where workers connect nodes and struts according to the design specifications. The assembly may be done in sections, creating larger modules that can be lifted into place.

During this phase, quality control is essential. Each connection is checked to ensure it meets the required tolerances and specifications. The use of specialized tools and techniques, such as torque wrenches and non-destructive testing methods, helps guarantee the integrity of the assembled space frame roof.

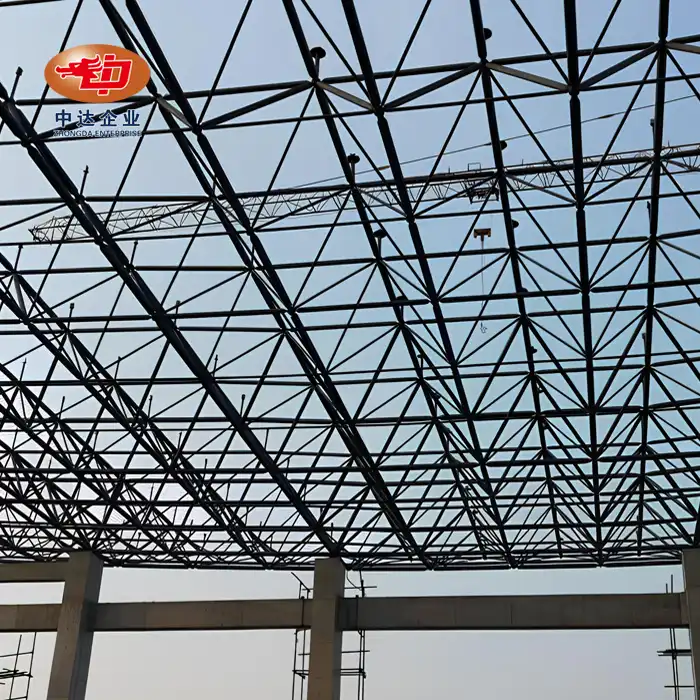

Lifting and Positioning the Space Frame

Once the space frame sections are assembled, they are carefully lifted into position using cranes or other lifting equipment. This is often one of the most critical and visually impressive stages of the installation process. The lift is carefully choreographed, with riggers and crane operators working in close coordination to ensure the structure is raised safely and accurately.

As the space frame is lifted, it's gradually connected to the support structure. This process requires precise alignment and may involve temporary bracing to maintain stability during installation. Once in its final position, the connections between the space frame and the support structure are secured and inspected.

Finishing Touches and Quality Assurance

Installing Cladding and Roofing Materials

With the space frame structure in place, the next step is to install the cladding and roofing materials. This could include glass panels, metal sheets, or other materials depending on the design specifications. The installation of these materials requires careful handling to prevent damage and ensure proper sealing against the elements.

During this phase, particular attention is paid to the interfaces between different materials and components. Proper sealing and flashing are crucial to prevent water infiltration and ensure the longevity of the roof system. Workers may use specialized tools and techniques to achieve the required level of precision in these critical areas.

Final Inspections and Adjustments

As the installation nears completion, a series of final inspections is conducted. These inspections cover structural integrity, weatherproofing, and aesthetic considerations. Any issues identified during these inspections are promptly addressed to ensure the space frame roof meets all design and performance criteria.

In some cases, minor adjustments may be necessary to achieve optimal performance. This could involve fine-tuning the tension in certain members or making slight alignment corrections. These adjustments are typically made by experienced technicians using specialized equipment.

Handover and Maintenance Planning

The final step in the installation process is the handover to the client or facility management team. This involves providing comprehensive documentation, including as-built drawings, maintenance manuals, and warranty information. A walkthrough of the completed installation is typically conducted to familiarize the client with the system and address any questions.

Additionally, a long-term maintenance plan is established to ensure the space frame roof continues to perform optimally throughout its lifespan. This plan may include periodic inspections, cleaning procedures, and guidelines for addressing potential issues that may arise over time.

Conclusion

Space frame roof installation is a complex yet rewarding process that results in a stunning architectural feature with exceptional performance characteristics. From meticulous planning and preparation to the final quality assurance checks, each step contributes to creating a roof system that is both functional and visually impressive. By understanding what to expect during the installation process, project stakeholders can better appreciate the skill and precision involved in bringing these innovative structures to life. As technology and techniques continue to evolve, we can look forward to even more efficient and impressive space frame roof installations in the future.

FAQs

1. How long does a typical space frame roof installation take?

The duration varies depending on the size and complexity of the project, but it can range from a few weeks to several months.

2. Are space frame roofs suitable for all climates?

Yes, space frame roofs can be designed to withstand various climatic conditions, including high winds, heavy snow loads, and seismic activity.

3. What maintenance does a space frame roof require?

Regular inspections, cleaning, and occasional resealing of joints are typically part of a space frame roof maintenance routine.

Expert Space Frame Roof Solutions | Zhongda Steel

At Zhongda Steel, we bring over 19 years of expertise to every space frame roof project. Our state-of-the-art 120,000 m2 facility and 60,000-ton annual capacity enable us to deliver precision-engineered solutions for clients worldwide. As a leading space frame roof manufacturer and supplier, we offer innovative designs, superior quality, and efficient installation processes. For unparalleled space frame roof solutions, contact our expert team at Ava@zd-steels.com.

References

1. Smith, J. (2022). Advanced Techniques in Space Frame Roof Design and Installation. Journal of Architectural Engineering, 28(3), 105-120.

2. Brown, A., & Johnson, L. (2021). Safety Considerations for Large-Scale Space Frame Installations. Construction Safety Review, 15(2), 45-60.

3. Chen, X., et al. (2023). Innovative Materials in Modern Space Frame Roof Systems. Materials Science and Engineering: A, 845, 143502.

4. Thompson, R. (2020). Space Frame Structures: From Concept to Completion. Architectural Press, London.

5. Wilson, E., & Davis, M. (2022). Environmental Performance of Space Frame Roofs in Various Climates. Energy and Buildings, 255, 111668.

6. Yamamoto, K. (2021). Quality Control Measures in Prefabricated Space Frame Assembly. International Journal of Construction Management, 21(7), 721-735.

_副本_1754115287719.jpg)

_1754030104098.png)