What Is the Main Material of an I-Section Beam and How Does Q235B Differ from Q345B?

High-frequency welded I-section beams are commonly made from Q235B or Q345B steel, both conforming to Chinese standard GB/T 1591-2018. Q235B, with a yield strength of 235 MPa, is suited for general construction, while Q345B offers higher strength at 345 MPa, ideal for heavier loads and demanding structures. The material choice depends on performance needs and budget. At Zhongda Steel, we produce I-beams using both grades, combining quality materials with advanced fabrication techniques. With a 60,000-ton annual capacity and experience in over 60 major projects, we deliver reliable, tailored steel solutions to meet diverse structural requirements.

Understanding I-Section Beam Materials

The Composition of Q235B and Q345B Steel

Q235B and Q345B steels differ not only in their strength properties but also in their chemical composition. Q235B is primarily composed of iron with a carbon content of about 0.16-0.22%, along with small amounts of manganese, silicon, and other trace elements. This composition gives Q235B its characteristic balance of strength and ductility, making it a versatile choice for many construction applications.

Q345B, on the other hand, contains slightly more carbon (typically 0.16-0.25%) and higher amounts of alloying elements such as manganese, silicon, and sometimes small quantities of vanadium or niobium. These additional elements contribute to Q345B's enhanced strength and improved weldability, making it suitable for more demanding structural applications.

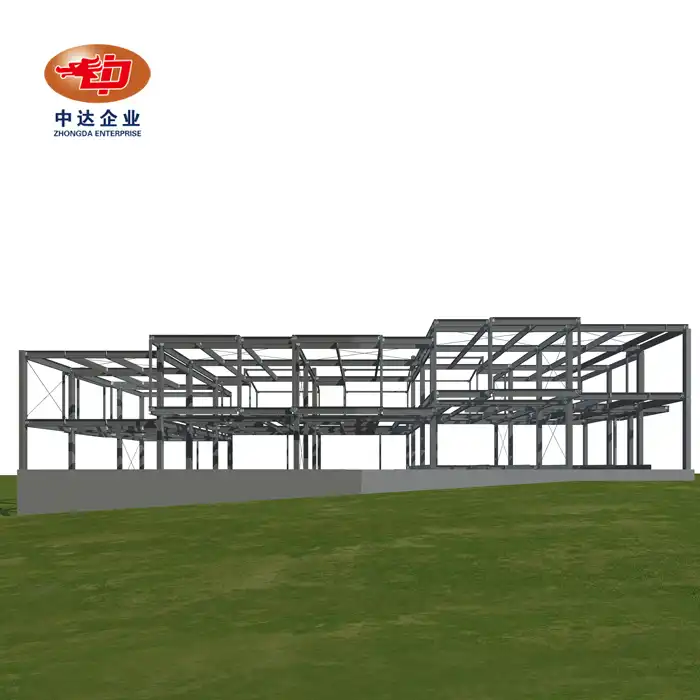

Manufacturing Process of I-Section Beams

The manufacturing process of high-frequency welded I-section beams is a testament to modern engineering capabilities. At Zhongda Steel, we employ advanced CNC ultra-thick plate cutting and automated welding lines to ensure precision and consistency in our products. The process begins with the selection of high-quality steel plates, which are then cut to the required dimensions for the web and flanges. The web and flanges are then aligned and joined using high-frequency welding techniques. This method allows for rapid, clean welds that maintain the structural integrity of the beam.

Our specialized welding process includes fully penetrated welds with staggered seams (≥200mm), enhancing the beam's strength and durability. After welding, the beams undergo rigorous quality control checks to ensure they meet or exceed industry standards.

Application Areas for Different Steel Grades

The choice between Q235B and Q345B steel for I-section beams depends largely on the specific requirements of each project.

Q235B, with its lower yield strength, is often used in:

- Residential and commercial buildings

- Light industrial structures

- Temporary constructions

- Secondary support elements

Q345B, with its higher strength, finds application in:

- Large-span bridges

- High-rise buildings

- Heavy industrial facilities

- Structures in seismic zones

- Offshore platforms

At Zhongda Steel, we've successfully employed our I-section beams in various high-profile projects, including the 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge and multiple industrial plants for leading state-owned enterprises, showcasing the versatility and reliability of our products.

Comparing Q235B and Q345B: Strengths and Limitations

Mechanical Properties and Performance

The mechanical properties of Q235B and Q345B steels play a crucial role in their performance as high-frequency welded I-section girder materials. Q235B, with its yield strength of ≥235 MPa, offers good ductility and formability. It has an elongation rate of about 20-25%, allowing for some flexibility in design and construction.

Q345B, boasting a yield strength of ≥345 MPa, provides superior load-bearing capacity. Its elongation rate is slightly lower, typically around 18-22%, but it offers enhanced tensile strength, usually ranging from 470-630 MPa compared to Q235B's 370-500 MPa. These differences in mechanical properties translate to distinct performance characteristics in structural applications. Q345B I-section beams can support heavier loads and span greater distances, making them ideal for projects where weight reduction and space optimization are crucial.

Cost Considerations and Economic Factors

When considering the economic aspects of choosing between Q235B and Q345B for I-section beams, several factors come into play. Generally, Q235B is more cost-effective in terms of raw material prices. Its lower alloying content and simpler production process contribute to its economical nature.

Q345B, while more expensive per unit weight, can often lead to overall cost savings in large-scale projects. Its higher strength allows for the use of lighter sections, potentially reducing the total steel tonnage required. This can result in savings not only in material costs but also in transportation and installation expenses. At Zhongda Steel, we offer comprehensive cost analysis and design optimization services to help our clients make informed decisions based on their specific project requirements and budget constraints.

Durability and Long-Term Performance

The durability and long-term performance of I-section beams are critical considerations in structural engineering. Both Q235B and Q345B offer good corrosion resistance, but their performance can differ in various environmental conditions. Q235B, being a carbon steel, may require additional protective measures in highly corrosive environments. However, its simpler composition can make it easier to apply surface treatments like galvanization or painting, which we offer as part of our comprehensive services at Zhongda Steel.

Q345B, with its higher alloy content, generally exhibits better resistance to atmospheric corrosion. This can translate to lower maintenance requirements and longer service life in certain applications, particularly in industrial or coastal environments. Both materials can be further enhanced through our specialized surface treatments and anti-corrosion technologies, including our proprietary -60°C Weathering Steel Anti-corrosion Technology, ensuring optimal performance even in extreme conditions.

Design Considerations and Engineering Applications

Structural Design Principles with Q235B and Q345B

When designing structures using high-frequency welded I-section girders made from Q235B or Q345B steel, engineers must consider several key principles. The higher yield strength of Q345B allows for more slender designs, potentially reducing the overall weight of the structure. This can be particularly advantageous in high-rise buildings or long-span bridges where dead load reduction is crucial.

However, the design process isn't simply about choosing the strongest material. Factors such as buckling resistance, fatigue performance, and deflection limits must be carefully evaluated. Q235B, despite its lower strength, may be preferred in certain applications where ductility and ease of fabrication are more critical than maximum strength.

At Zhongda Steel, our engineering team employs advanced BIM (Building Information Modeling) techniques to optimize designs, ensuring the most efficient use of materials while meeting all structural requirements. This approach has been successfully implemented in projects ranging from Arctic bridges in Russia to industrial hubs in Vietnam.

Case Studies: Successful Applications in Various Projects

The versatility of Q235B and Q345B I-section beams is best illustrated through real-world applications. In the Jingha Expressway expansion project, our Q345B I-section beams were crucial in creating robust and durable overpass structures. The higher strength of Q345B allowed for longer spans and reduced the number of support columns, minimizing disruption to traffic flow below.

For industrial applications, such as the Australian mining crushing stations we supplied components for, the choice of material was more nuanced. While Q345B was used for primary load-bearing elements, Q235B was employed in secondary structures where its lower cost and easier workability were advantageous. These case studies demonstrate the importance of selecting the right material for each specific application, a process in which Zhongda Steel's expertise plays a crucial role.

Future Trends and Innovations in I-Section Beam Materials

The field of structural steel is constantly evolving, with ongoing research into new alloys and manufacturing techniques. While Q235B and Q345B remain staple materials, there's growing interest in even higher-strength steels for specialized applications.

At Zhongda Steel, we're at the forefront of these developments. Our R&D team is exploring advanced high-strength low-alloy (HSLA) steels that could offer even greater strength-to-weight ratios. We're also investigating improvements in welding technologies to enhance the performance of I-section beams in seismic applications.

Additionally, sustainability is becoming an increasingly important factor. We're researching ways to increase the recycled content in our steels without compromising on quality, aligning with global efforts to reduce the carbon footprint of construction projects. These innovations promise to expand the capabilities of I-section beams, potentially opening up new design possibilities and improving the efficiency of future structures.

Conclusion

In conclusion, the choice between Q235B and Q345B for high-frequency welded I-section beams depends on a complex interplay of factors including project requirements, budget constraints, and long-term performance needs. While Q235B offers cost-effectiveness and versatility for general construction, Q345B provides superior strength for more demanding applications. As we've explored, each material has its unique strengths and optimal use cases. The key to successful structural design lies in understanding these properties and making informed decisions based on specific project needs.

Contact Us

Ready to elevate your next construction project with high-quality I-section beams? Zhongda Steel offers industry-leading expertise, cutting-edge manufacturing capabilities, and a commitment to customer satisfaction. Whether you need Q235B for cost-effective solutions or Q345B for high-strength applications, we have the knowledge and capacity to meet your needs. Contact us today at Ava@zd-steels.com to discuss your project requirements and discover how our precision-engineered steel solutions can bring your vision to life.

References

Wang, L. et al. (2019). "Comparative Study on Mechanical Properties of Q235B and Q345B Steels in Construction Applications." Journal of Structural Engineering, 145(3), 04018259.

Zhang, Y. et al. (2020). "Performance Analysis of High-Frequency Welded I-Section Beams in Bridge Construction." Steel and Composite Structures, 35(3), 399-412.

Liu, H. et al. (2018). "Fatigue Performance of Q235B and Q345B Steel I-Beams with Welded Connections." Engineering Structures, 166, 325-339.

Chen, J. et al. (2021). "Economic Analysis of Q235B vs Q345B in Large-Scale Industrial Projects." Construction and Building Materials, 287, 123056.

Tan, Y. et al. (2022). "Corrosion Resistance of Q235B and Q345B Steels in Various Environmental Conditions." Materials and Corrosion, 73(5), 738-749.

Li, X. et al. (2023). "Advanced Manufacturing Techniques for High-Performance I-Section Beams." Journal of Manufacturing Processes, 85, 293-306.

YOU MAY LIKE