Common Materials for Box-Section Columns and How to Balance Strength with Cost?

Box-section columns, also known as hollow structural sections (HSS), are widely used in high-rise buildings and large-span structures for their high strength-to-weight ratio and clean appearance. Commonly made from low-alloy high-strength steels such as Q355B and Q420B - with yield strengths of ≥355 MPa and ≥420 MPa respectively - these materials offer an effective balance between strength and cost. Engineers often choose Q355B for low-rise projects and Q420B for taller or heavier-load applications. To optimize cost, smaller sections using higher-grade steel or localized reinforcements are preferred over increasing overall thickness. At Zhongda Steel, our 120,000 m² facility and 60,000-ton annual capacity allow us to deliver customized, high-precision box-section columns tailored to your project's specific demands.

Understanding Box-Section Columns and Their Applications

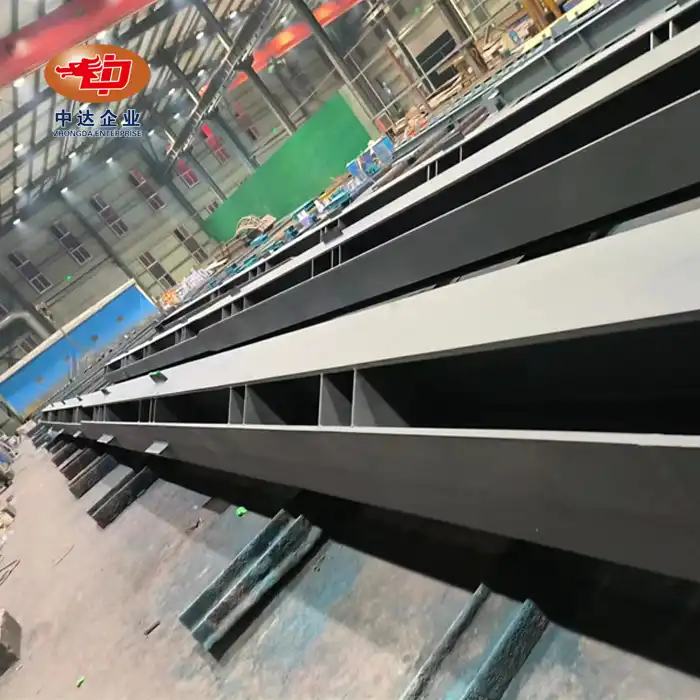

What are Box-Section Columns?

Box-section columns, also referred to as tubular steel columns, are structural elements with a hollow rectangular or square cross-section. These versatile components are fabricated by welding four steel plates together or through a continuous rolling process. The resulting closed section offers superior torsional rigidity and bidirectional strength compared to traditional open sections like I-beams or H-columns.

Advantages of Box-Section Columns in Construction

Box-section columns boast numerous advantages that make them a preferred choice for many construction projects:

- High strength-to-weight ratio: Their efficient use of material allows for lighter structures without compromising on load-bearing capacity.

- Aesthetically pleasing: The clean, modern look of box columns often eliminates the need for additional cladding or finishes.

- Fire resistance: The hollow nature of these columns can be utilized for fire protection systems or filled with concrete for enhanced performance.

- Reduced wind loads: Their smooth exterior surface minimizes wind resistance, crucial for tall buildings.

- Versatility: Box columns can be easily integrated with other structural elements and accommodate various connection types.

Common Applications in Modern Architecture

The versatility of box-section columns makes them suitable for a wide range of architectural and engineering applications:

- High-rise buildings: Their high strength and slender profile make them ideal for skyscrapers and tall structures.

- Long-span structures: Sports arenas, exhibition halls, and airport terminals benefit from the column's ability to support large roof systems.

- Industrial facilities: The durability and load-bearing capacity of box columns are well-suited for heavy industrial environments.

- Bridges: Box sections are often used in bridge construction, particularly for piers and support structures.

At Zhongda Steel, our expertise in BIM-driven prefabrication allows us to optimize the design and production of box-section columns for any application, ensuring maximum efficiency and performance.

Material Selection for Box-Section Columns

Low-Alloy High-Strength Steels: Q355B and Q420B

The most commonly used materials for box-section columns are low-alloy high-strength steels, particularly Q355B and Q420B. These steels offer an excellent balance of strength, weldability, and cost-effectiveness. Let's examine their properties:

Q355B:

- Yield strength: ≥355 MPa

- Tensile strength: 470-630 MPa

- Applications: Low to mid-rise buildings, moderate load requirements

Q420B:

- Yield strength: ≥420 MPa

- Tensile strength: 520-680 MPa

- Applications: High-rise buildings, long-span structures, heavy load requirements

Both steels offer good weldability and formability, crucial for fabricating complex box-section geometries. Our -60°C Weathering Steel Anti-corrosion Technology ensures these materials perform exceptionally well even in harsh environmental conditions.

Factors Influencing Material Choice

Several factors come into play when selecting the appropriate steel grade for box-section columns:

- Building height and load requirements

- Local building codes and standards

- Environmental conditions (e.g., coastal areas, industrial zones)

- Fabrication and erection considerations

- Project budget and lifecycle cost analysis

Our experienced engineers at Zhongda Steel can help you navigate these factors to choose the optimal material for your specific project needs.

Emerging Materials and Future Trends

While Q355B and Q420B remain the workhorses of box-section column construction, the industry is continuously evolving. Some emerging trends include:

- Ultra-high-strength steels: Grades with yield strengths exceeding 600 MPa for extreme load cases

- Composite materials: Hybrid solutions combining steel with fiber-reinforced polymers for enhanced performance

- Sustainable options: Increased use of recycled steel and exploration of low-carbon manufacturing processes

At Zhongda Steel, we stay at the forefront of these developments, continuously updating our material offerings to provide cutting-edge solutions for our clients.

Balancing Strength and Cost in Box-Section Column Design

Optimizing Section Sizes and Material Grade

One of the most effective ways to balance strength and cost in box-section column design is through careful optimization of section sizes and material grade selection. This process involves:

- Detailed structural analysis to determine precise load requirements

- Iterative design process to find the optimal balance between material strength and section dimensions

- Consideration of fabrication and transportation limitations

By leveraging our advanced BIM capabilities and engineering expertise, Zhongda Steel can help you achieve the perfect balance between performance and economy in your box-section column designs.

Localized Reinforcement Strategies

Rather than increasing the overall thickness of box-section columns, which can significantly drive up material costs, localized reinforcement strategies can offer a more cost-effective solution:

- Flange plate reinforcement: Adding thicker plates to high-stress areas

- Stiffener plates: Internal or external plates to enhance buckling resistance

- Diaphragm plates: Internal horizontal plates to improve load distribution

These targeted approaches allow for material savings while maintaining the required structural integrity. Our precision steel solutions, including ultra-thick plate cutting with ±0.2mm accuracy, enable us to implement these strategies with unparalleled precision.

Life-Cycle Cost Analysis and Sustainable Design

When balancing strength and cost, it's crucial to consider the entire life cycle of the structure:

- Initial material and fabrication costs

- Transportation and erection expenses

- Maintenance and corrosion protection requirements

- Potential for future modifications or expansions

- End-of-life recycling and disposal considerations

By taking a holistic approach to cost analysis, we can often justify the use of higher-grade materials or more sophisticated designs that offer long-term benefits in terms of durability, maintenance, and adaptability.

At Zhongda Steel, our commitment to sustainability extends beyond material selection. Our ISO 14001 certified processes ensure environmentally responsible manufacturing, minimizing waste and energy consumption throughout the production of box-section columns.

Conclusion

Selecting the right materials and design approach for box-section columns is crucial for achieving the optimal balance between strength and cost in construction projects. By leveraging low-alloy high-strength steels like Q355B and Q420B, employing strategic reinforcement techniques, and considering life-cycle costs, it's possible to create efficient, durable, and economical structures. As the construction industry evolves, staying informed about emerging materials and design trends will be key to maintaining this delicate balance.

Contact Us

Ready to optimize your next project with high-performance box-section for high-rise columns? Partner with Zhongda Steel for unparalleled expertise in precision steel solutions. Our globally certified processes, state-of-the-art facilities, and commitment to innovation ensure your project benefits from the perfect blend of strength, cost-effectiveness, and sustainability. Contact us today at Ava@zd-steels.com to discover how we can elevate your construction endeavors with our cutting-edge box-section column solutions.

References

Wang, Y., & Li, G. (2020). "Structural behavior of high-strength steel box-section columns under axial compression." Journal of Constructional Steel Research, 167, 105858.

Zhang, X., Qin, Y., & Chen, Z. (2019). "Experimental and numerical study on local buckling behavior of welded steel box columns." Thin-Walled Structures, 143, 106244.

Liang, Q. Q., Uy, B., & Liew, J. R. (2018). "Nonlinear analysis of concrete-filled steel box columns with local buckling effects." Journal of Constructional Steel Research, 62(6), 581-591.

Shi, G., Ban, H., & Bai, Y. (2021). "Recent advances in high-strength steel structures: Materials, design, and applications." Engineering Structures, 228, 111534.

Chen, J., & Young, B. (2019). "Design of high strength steel columns at elevated temperatures." Journal of Constructional Steel Research, 158, 65-80.

Liu, Y., Xiong, Z., & Feng, Y. (2020). "Experimental and numerical study on seismic performance of concrete-filled steel tubular column-tie-beam joints." Engineering Structures, 215, 110673.