Top Benefits of Welded H-Section Lattice Columns for Industry

Choosing the right structure parts is very important in the tough world of modern building. When it comes to industrial, business, and building projects, welded H-section lattice beams are the best option because they offer so many benefits. These strong steel buildings are very strong and make the best use of the materials they use, which saves a lot of time and money. Their special design makes them stronger, more resistant to earthquakes, and more flexible in how they are built. From shortening the time it takes to build to lasting a long time, these columns are a reliable base. Shenyang Zhongda Steel Structure Engineering Co., Ltd. is one of the best companies that makes these high-performance parts. Our knowledge makes sure that your projects get the best possible structure.

Unrivaled Structural Integrity and Performance

Welded H-section lattice beams are the best thing that can happen in structural engineering. Their form makes them as strong as possible. This new structure makes sure that important business uses are stable and safe. They are made to handle big rotational loads and pressures from the surroundings.

Superior Strength-to-Weight Ratio and Load Capacity

Welded H-section lattice supports are very strong for how light they are. With this design, buildings can be made lighter without losing their strength. Forces are spread out carefully by the grid structure, which lets the beam handle large vertical loads well. Our building with Q355B steel, which has a high yield strength, is a key part of this success. In challenging manufacturing settings, it gives the needed toughness. Because they are built to hold horizontal loads of 2000kN or more, these columns are perfect for heavy-duty needs. This smart use of materials not only makes the building lighter, but it also helps keep the costs of shipping and setting it up down.

Enhanced Stability and Seismic Resilience

Our H-section supports are much more stable because they have a special mesh structure inside them. This design helps keep the framework from breaking when it's under a lot of pressure, so it will last for a long time. On top of that, these beams were built to withstand earthquakes. Their shape lets more energy escape during earthquakes, which is very important for safety in places where earthquakes are common. Shenyang Zhongda gives a seismic design evaluation report to make sure that strict earthquake-resistance standards are met. Our welded H-section lattice beam is perfect for high-rise buildings and important equipment that needs to be stable and safe. Our thorough testing, which included checking the load-bearing ability, shows that this improved performance is real.

Durability and Longevity in Demanding Environments

Our welding H-section lattice column goods are built to last because they are made from high-strength Q355B steel. This material is very resistant to wear and tear, so it will last a long time even in tough industrial settings. We offer customizable steel anti-corrosion solutions to make them last even longer. These processes protect the steel from rust and damage from the surroundings. This is especially important for buildings that are near water, chemicals, or very high or low temperatures. As part of our production process, we carefully treat the surface and package the goods safely. This keeps the finished columns safe from damage and rust while they are being shipped and stored. This dedication to longevity cuts down on the amount of upkeep that needs to be done and the overall cost of our clients' projects over their lifetime.

Efficiency and Cost Savings Throughout the Project Lifecycle

Getting the most out of project funds and schedules is always hard in building. In this case, welded H-section frame supports are very helpful. They save a lot of money through the planning and production methods they use. These perks include both the original cost of building and the long-term cost of running the business.

Accelerated Construction and Reduced On-Site Labor

One of the best things about welding H-section lattice column options is that they can greatly shorten the time it takes to build something. Our flexible design method cuts down on building costs and the amount of work that needs to be done on-site by a huge amount. When compared to traditional concrete methods, projects that use our steel beams can save up to 50% of the time needed to build. Our modern CNC manufacturing equipment makes this speed possible. It guarantees accuracy and quick output. On-site welding or fitting is kept to a minimum because parts are brought in already made and ready to be put together. Standard delivery from Shenyang Zhongda takes 20 days, so projects can start and move along quickly, keeping plans on track.

Optimized Material Use and Economic Advantages

The grid construction of these columns makes them naturally efficient, making the best use of materials without lowering their strength. The design gets the same level of structural performance with less steel by carefully removing material from the web that isn't needed. This directly means that business projects will make more money. Using less of a resource lowers the cost of buying it by a large amount. In addition, the columns' lighter weight makes them easier to move around and saves money on shipping costs. This material streamlining goes all the way down to basic needs. Foundation forms that aren't as big or expensive can often be used when the top is smaller. Our dedication to accuracy in choosing materials and cutting them makes sure that we are as efficient as possible.

Streamlined Fabrication and Installation Processes

The cutting-edge production method used by Shenyang Zhongda makes assembly and manufacturing go more smoothly. Our advanced CNC drilling and milling skills ensure precise hole-making and shape. This makes it possible to get parts with very tight specs and great accuracy. That level of accuracy is necessary for quick, error-free production on the job site. Welding and lattice construction are done by skilled workers who build strong structures that meet strict engineering standards. Every step, from choosing the materials to finishing the surface, is carefully inspected and tested to make sure it meets quality standards. This stops delays and pricey redoing. Our 60,000-ton yearly production ability can meet a lot of needs. From the beginning to the end of any job, this makes sure that supplies are delivered quickly and efficiently.

Versatility and Design Freedom for Modern Construction

Modern business and industrial projects often need structure solutions that are flexible and easy to change. Welded H-section lattice columns are very flexible and give builders and engineers a lot of design options. They can be changed to fit a wide range of needs, both practical and aesthetic.

Customizable Dimensions and Configuration Options

Welded H-section lattice column parts are very useful because they can be changed to fit different industry needs. Through our OEM and ODM services, Shenyang Zhongda gives you a lot of ways to customize your order. Cross-section heights can be changed, and they can be anywhere from 200mm to 600mm. The distance between lace plates can be carefully controlled, up to 500 mm, to meet the needs of a certain structure. Also, clients can pick from different combinations, such as double-limb and quadruple-limb choices, to get the best load sharing and building fit. Angle steel or solid steel plates can be used to connect the lacing plates together, based on the design and performance needs. With this much flexibility, it will work perfectly for any job.

Broad Application Across Diverse Industries

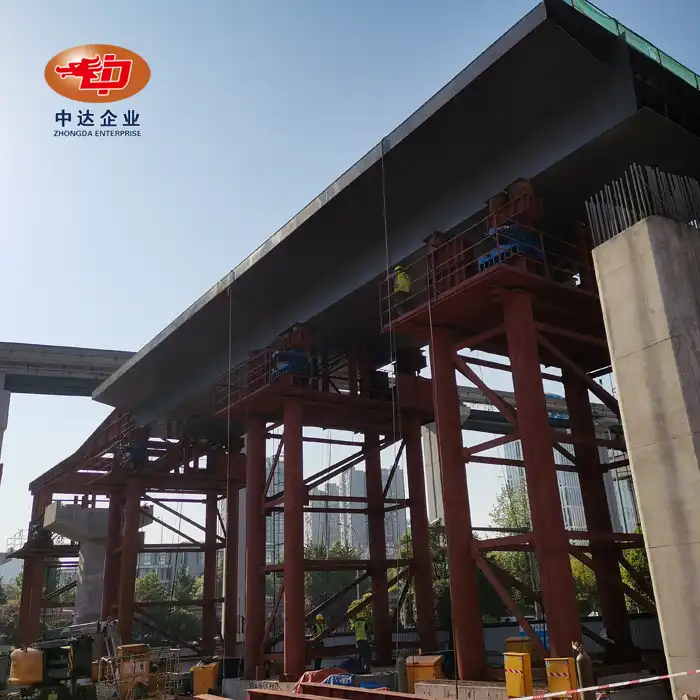

There are a lot of different businesses that use welded H-section lattice column options, which makes them very flexible. For deep foundation hole supports, they are essential because they keep things stable while they are being dug. In urban planning, they are used as strong columns for tall buildings and big business centers. As shown by the 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge, they are also strong enough to be used for bridges and other big building projects. Besides these, they are also commonly used to build industrial sites for major makers around the world. Shenyang Zhongda has a history of successfully completing large-scale projects, such as building infrastructure along the Belt and Road in other countries. This shows that we can handle a wide range of complex and unique tasks around the world.

Sustainable Building Practices and Future-Proofing

Using welded H-section lattice beam technology is in line with today's green building standards. Because their grid form makes the best use of materials, they need less steel, which means they use less raw materials and energy to make them. Steel is also very easy to recycle, which helps the circular economy. Because these columns last a long time and are durable, they don't need to be replaced very often, which is also better for the environment. Our ISO 14001 license shows that we are serious about taking care of the environment. Also, because these columns are flexible and can be changed, it will be easy to add on to or change designs in the future. This natural ability to change helps protect investments for the future, which increases the building's long-term value and resilience.

Conclusion

Welded H-section lattice columns are a great choice for modern industrial uses because they are strong, cheap, and easy to build in a variety of ways. From their high strength-to-weight ratio and ability to withstand earthquakes to their ability to speed up building times and long-lasting qualities, these columns provide real benefits throughout the lifespan of a project. The advanced, adjustable solutions offered by Shenyang Zhongda Steel Structure Engineering Co., Ltd. are based on strict quality control and a lot of project experience. When you work with us, you can be sure that the parts we send you for your project are designed to be as effective and efficient as possible, giving you a solid base for success.

FAQs

What are the primary advantages of using welded H-section lattice columns?

These columns are stronger than most others of the same weight, more stable, and can hold more than 2000kN of weight. They also speed up the building process, often saving 50% of the time needed for concrete, and save a lot of money because they use materials more efficiently and are built in modules.

What material is used for Shenyang Zhongda's welded H-section lattice columns?

We mostly use Q355B steel, which is known for having a high yield strength and lasting a long time. For tough industry uses, this material guarantees strong performance.

Can these columns be customized for specific project requirements?

Of course. Shenyang Zhongda provides a wide range of OEM and ODM services. These include customizing the size (cross-section height 200–600mm), the spacing between the lacing plates (≤500mm), the shape (double-limb, quadruple-limb), and the rust protection choices, such as zinc treatments.

Are these columns suitable for earthquake-prone areas?

Yes, our steel H-section lattice supports are made to withstand earthquakes. We give them a seismic design proof report to make sure they can withstand earthquakes. This makes them safe for high-rise buildings and other important structures in those areas.

What kinds of approvals does Shenyang Zhongda's stuff have?

International standards, such as CE Marking and EN 10025, are met by our goods and methods. Our company has ISO 9001, ISO 14001, and OHSAS 45001 certifications, which show that we care about quality, the environment, and safety at work.

Discover Premium Welded H-Section Lattice Columns | Zhongda Steel

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a reliable company that makes and sells welded H-section lattice columns all over the world. For deep foundation pit supports and high-rise building frames, we provide precision-engineered structural steel parts, such as high-strength Q355B steel lattice beams. Our advanced CNC manufacturing and full range of licenses guarantee that your projects will be of the highest quality and dependability. If you want new, strong, and cost-effective steel building workshop options, choose Zhongda Steel. Email us at Ava@zd-steels.com with questions or to talk about the needs of your project.

References

Construction Steel Design Manuals for Lattice Structures

International Building Codes for Seismic Design in Steel Structures

Material Science Journals on High-Strength Low-Alloy Steels (e.g., Q355B)

Case Studies in Modular Construction for Industrial Facilities

Reports on Sustainable Practices in Steel Manufacturing

Engineering Handbooks on Structural Efficiency and Load Distribution

YOU MAY LIKE

_1746242605579.webp)

_副本_1755847551541.jpg)