The Art and Science of Custom Steel Truss Beam Design

Engineering Excellence: Tailoring Trusses to Project Specifications

At the heart of every successful custom steel truss beam lies meticulous engineering. Zhongda Steel's team of expert engineers employs state-of-the-art Finite Element Analysis (FEA) to optimize stress distribution, resulting in structures that boast up to 25% greater load-bearing capacity compared to conventional designs. This advanced approach allows for the creation of trusses that span impressive distances of 20 to 80 meters without intermediate supports, opening up new possibilities for open, column-free spaces in commercial and industrial settings.

The use of high-strength Q420D steel further enhances the performance of these custom trusses. By utilizing H-shaped upper and lower chords combined with round pipes or angle steel web members, Zhongda's engineers create structures that efficiently transfer loads while minimizing material usage. This not only results in cost-effective solutions but also contributes to the overall sustainability of projects by reducing the carbon footprint associated with steel production and transportation.

Versatility in Design: Meeting Unique Architectural Challenges

One of the key advantages of custom fabricated steel truss beams is their ability to adapt to diverse architectural requirements. Zhongda Steel offers a range of customization options, including curved trusses and triangular sections, which are particularly well-suited for stadiums and airport terminals. These specialized designs allow architects to create sweeping, organic forms that would be impossible with traditional structural elements.

The flexibility of custom trusses extends beyond their shape. By carefully selecting the size and configuration of individual components, engineers can fine-tune the performance characteristics of each truss to meet specific project needs. This might involve optimizing for wind loads in exposed locations, accommodating unusual load distributions, or integrating with other building systems such as HVAC and lighting.

Quality Assurance: Ensuring Structural Integrity and Longevity

The success of any custom steel truss beam project hinges on impeccable quality control. Zhongda Steel's commitment to excellence is evident in its ISO 9001-certified processes, which govern every stage of production. From material selection to final assembly, rigorous inspections and tests ensure that each component meets or exceeds industry standards.

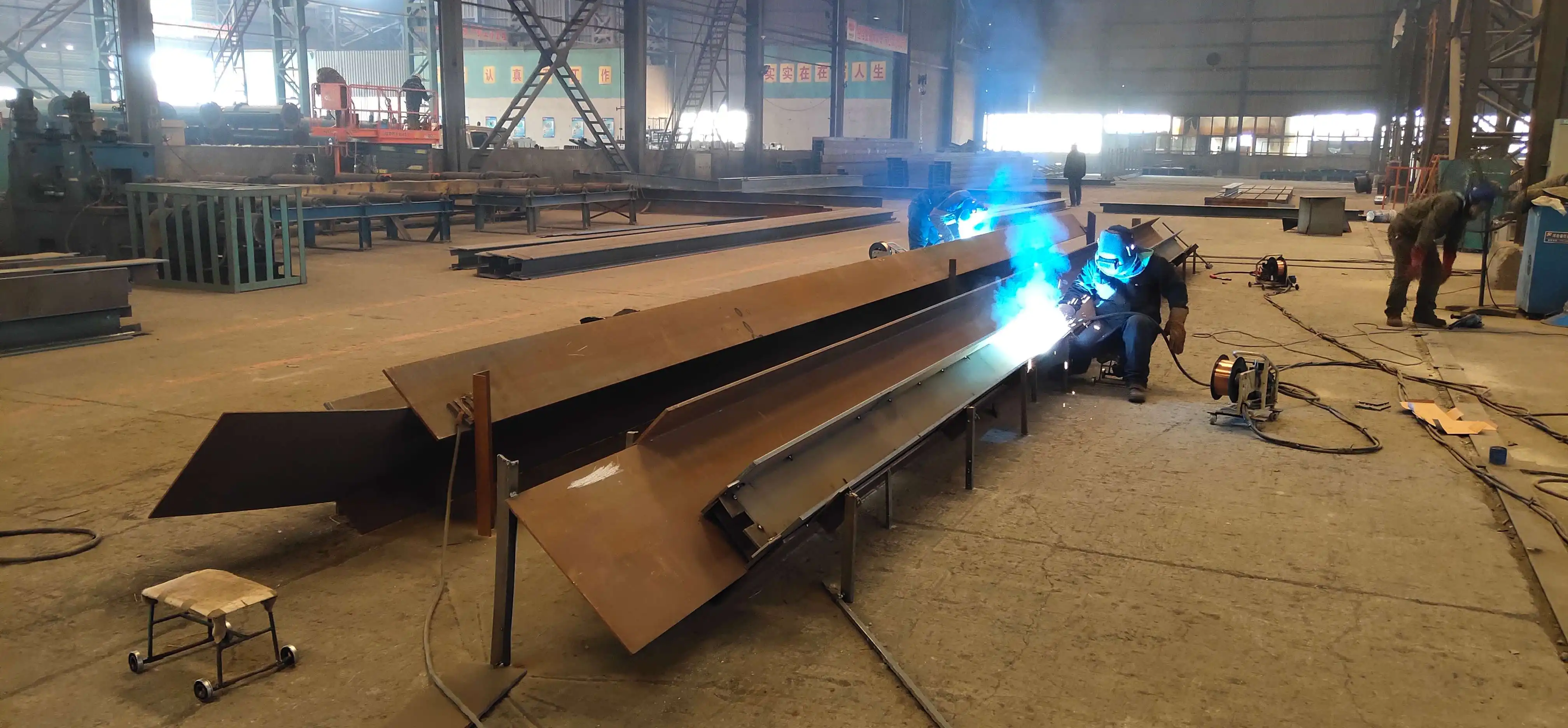

Notably, Zhongda's welding processes are certified to ISO 3834 standards, guaranteeing the highest level of quality in this critical aspect of truss fabrication. Additionally, bolt connection nodes comply with AISC standards, providing engineers and architects with the assurance that these crucial joining points will perform reliably under all anticipated loads.

Innovative Fabrication Techniques for Superior Steel Trusses

Cutting-Edge Manufacturing: Precision and Efficiency

The production of custom steel truss beams at Zhongda Steel leverages cutting-edge technology to achieve unparalleled precision and efficiency. Advanced CNC equipment enables intricate cuts and shaping with micron-level accuracy, ensuring that each component fits perfectly within the larger assembly. This precision is particularly crucial for long-span trusses, where even small deviations can compound over distance and compromise structural integrity.

Automated welding lines, equipped with state-of-the-art robotic systems, create strong and uniform welds that eliminate the variability associated with manual welding. This not only enhances the strength and reliability of the trusses but also allows for faster production times, helping to meet tight project deadlines without sacrificing quality.

Material Innovation: High-Performance Steel for Demanding Applications

The choice of material plays a crucial role in the performance of custom steel truss beams. Zhongda Steel's use of Q420D high-strength steel represents the cutting edge of material science in structural engineering. This advanced alloy offers an exceptional strength-to-weight ratio, allowing for lighter, more efficient truss designs that can span greater distances with less material.

Moreover, Zhongda's expertise in ultra-thick plate cutting (±0.2mm tolerance) and -60°C Weathering Steel Anti-corrosion Technology opens up new possibilities for truss applications in extreme environments. From Arctic bridges to corrosive industrial settings, these material innovations ensure that custom fabricated trusses can withstand the harshest conditions while maintaining their structural integrity over decades of service.

BIM Integration: Streamlining Design and Construction

The complexity of custom steel truss beam projects demands advanced coordination tools, and Zhongda Steel is at the forefront of Building Information Modeling (BIM) integration. By providing detailed 3D diagrams and BIM models for assembly, Zhongda ensures that every stakeholder in the construction process has access to accurate, up-to-date information.

This BIM-driven approach facilitates clash detection, optimizes construction sequencing, and allows for virtual assembly trials before a single piece of steel is cut. The result is smoother on-site installation, reduced errors, and ultimately, faster project completion times. For clients, this translates to significant cost savings and a more predictable construction process.

Real-World Applications: Custom Steel Trusses in Action

Architectural Marvels: Stadiums and Airport Terminals

Custom fabricated steel truss beams have revolutionized the design of large-scale public venues. In stadium construction, curved trusses create sweeping rooflines that not only provide weather protection but also contribute to the iconic silhouettes that define modern sports arenas. The long spans achievable with these trusses allow for unobstructed sightlines, enhancing the spectator experience.

Similarly, airport terminals benefit from the expansive, column-free spaces that long-span steel trusses make possible. These structures create airy, light-filled concourses that can accommodate the ebb and flow of thousands of travelers. The flexibility of custom trusses also allows for easy integration of skylights and other architectural features that elevate the terminal design beyond mere functionality.

Industrial Applications: Bridging Gaps and Supporting Heavy Loads

The strength and versatility of custom steel truss beams make them ideal for demanding industrial applications. In bridge construction, such as the Shenyang Dongta Cross-Hunhe River Bridge project, which utilized an impressive 18,000-ton steel structure, these trusses demonstrate their ability to span significant distances while supporting heavy vehicular loads.

In manufacturing facilities and warehouses, long-span trusses create vast, open floor plans that maximize operational flexibility. The ability to customize truss designs allows for the integration of overhead cranes, conveyor systems, and other specialized equipment, tailoring the structure to the specific needs of each industrial process.

Innovative Structures: Pushing the Boundaries of Design

Beyond traditional applications, custom fabricated steel truss beams are enabling architects and engineers to push the boundaries of structural design. Triangular section trusses, for example, are finding use in avant-garde buildings that challenge conventional forms. These unique structures serve not only as load-bearing elements but also as architectural features in their own right, blurring the line between form and function.

In sustainable architecture, the efficiency of custom steel trusses contributes to reducing the overall environmental impact of buildings. By minimizing material use and facilitating the integration of green technologies such as solar panels and natural ventilation systems, these trusses play a crucial role in creating the eco-friendly structures of tomorrow.

Conclusion

Custom fabricated steel truss beams represent the pinnacle of structural engineering, offering unparalleled versatility, strength, and efficiency for unique projects across various sectors. By leveraging advanced materials, innovative design techniques, and cutting-edge fabrication processes, companies like Zhongda Steel are enabling architects and engineers to bring even the most ambitious visions to life. As we continue to push the boundaries of what's possible in construction, these bespoke steel solutions will undoubtedly play a central role in shaping the skylines and infrastructure of the future.

Contact Us

Ready to elevate your next project with custom fabricated steel truss beams? Choose Zhongda Steel for unmatched quality, innovation, and expertise. Our long-span steel truss beams offer superior strength, flexibility, and cost-effectiveness for your most challenging designs. Contact us today at Ava@zd-steels.com to discover how our custom solutions can bring your vision to life.