How Durable Are Prefabricated Light Steel Villas?

Prefabricated light steel villas are exceptionally durable, often outlasting traditional construction methods by decades. With advanced galvanization techniques and high-quality steel, these structures can withstand harsh environmental conditions for 50-100 years or more. Their resistance to corrosion, seismic activity, and extreme weather makes them ideal for diverse climates. At Zhongda Steel, our prefab villas undergo rigorous testing, including SGS salt spray tests of ≥3000 hours, ensuring longevity even in coastal areas. This durability, combined with customizable designs and rapid assembly, makes our light steel villas a superior choice for sustainable, long-lasting housing solutions.

The Structural Integrity of Prefabricated Light Steel Villas

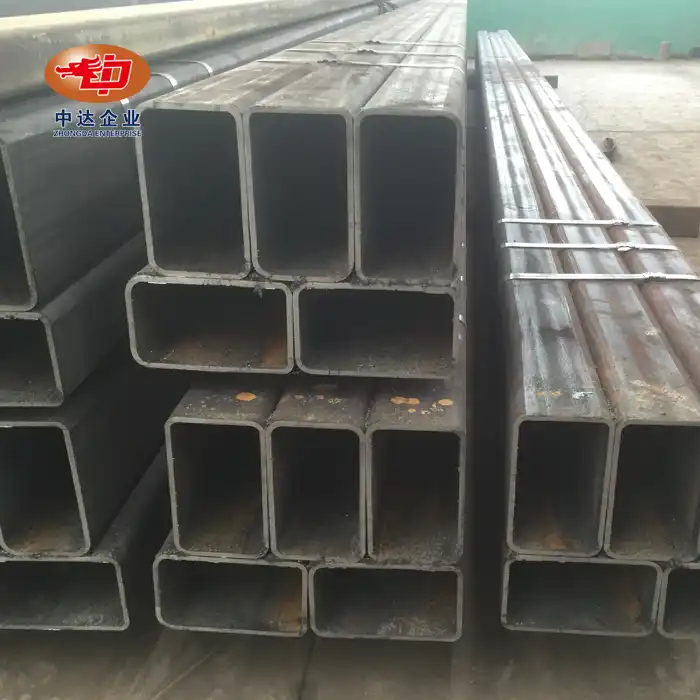

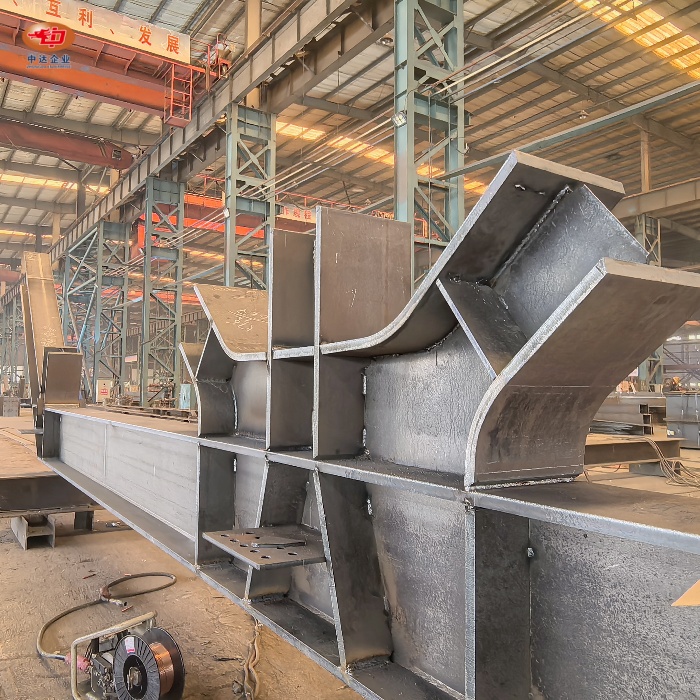

Advanced Steel Frame Technology

At the heart of our prefabricated light steel villas lies cutting-edge steel frame technology. We utilize ASTM A653 G90 galvanized steel with a 275g/㎡ zinc coating, providing unparalleled protection against corrosion. This high-grade material forms the backbone of our structures, offering superior strength-to-weight ratios compared to traditional building materials. The precision engineering of these frames ensures optimal load distribution, enhancing the overall structural integrity of the villa.

Seismic Resistance Capabilities

One of the most impressive aspects of our prefabricated light steel villas is their seismic resistance. Our structures have passed the rigorous Japan JIS A 4706 Test, demonstrating their ability to withstand Level 7 intensity earthquakes. This certification is a testament to the robust design and engineering principles we employ. The flexibility and ductility of steel allow these villas to absorb and dissipate seismic energy effectively, significantly reducing the risk of structural damage during earthquakes.

Weather Resistance and Longevity

Zhongda Steel's prefabricated villas are built to withstand diverse weather conditions. The galvanized steel frame resists rust and corrosion, even in humid or coastal environments. Our SGS Salt Spray Test results, showing resistance for ≥3000 hours, underscore this durability. Additionally, the customizable insulation options, ranging from 50 to 100mm of rock wool, provide excellent thermal performance. This not only enhances energy efficiency but also protects the structure from temperature-related stress, further extending its lifespan.

Customization and Versatility in Design

Flexible Size Options

Our prefabricated light steel villas offer remarkable versatility in design, catering to a wide range of needs and preferences. With customizable sizes ranging from 80 to 300㎡, we can accommodate everything from cozy vacation homes to spacious family residences. This flexibility allows developers and homeowners to optimize space utilization while maintaining the structural integrity that our steel frames provide. The modular nature of our designs also facilitates future expansions or modifications, ensuring that your investment can grow with your needs.

Aesthetic Customization

While durability is paramount, we understand the importance of aesthetics in creating a desirable living space. Our prefabricated villas can be finished with a variety of exterior options, including wood grain and stone grain textures. These finishes not only enhance the visual appeal but also provide an additional layer of protection against the elements. The ability to customize the exterior appearance allows our villas to blend seamlessly with various architectural styles and natural surroundings, making them suitable for diverse project requirements.

Smart Home Integration

Embracing modern living standards, our prefabricated light steel villas come with the option for pre-installed smart home wiring. This forward-thinking feature allows for easy integration of home automation systems, enhancing both comfort and energy efficiency. From automated climate control to advanced security systems, these smart capabilities add a layer of sophistication to the robust structure of our villas. The combination of durability and cutting-edge technology positions our prefabricated homes at the forefront of sustainable and intelligent housing solutions.

Environmental Impact and Sustainability

Eco-Friendly Construction Process

The construction of prefabricated light steel villas represents a significant leap forward in sustainable building practices. Our manufacturing process at Zhongda Steel is designed to minimize waste and reduce environmental impact. The precision fabrication of steel components in our controlled factory environment results in less material waste compared to traditional on-site construction. Additionally, the reduced construction time and fewer vehicle trips to the building site contribute to a lower carbon footprint for each project.

Energy Efficiency in Operation

The durability of our prefabricated villas extends beyond their structural integrity to their operational efficiency. The superior insulation properties of our designs, coupled with the thermal performance of steel, contribute to excellent energy efficiency. This translates to reduced heating and cooling costs for occupants, lowering the overall environmental impact of the building throughout its lifecycle. The option to integrate solar panels further enhances the sustainability profile of these structures, allowing for clean energy generation on-site.

Long-Term Environmental Benefits

The longevity of prefabricated light steel villas offers significant long-term environmental benefits. Their durability means less frequent need for repairs or replacements, reducing the demand for new construction materials over time. Furthermore, at the end of their lifecycle, steel components are 100% recyclable, aligning with circular economy principles. This recyclability, combined with the minimal waste during initial construction, makes our prefabricated villas a responsible choice for environmentally conscious developers and homeowners.

Conclusion

Prefabricated light steel villas represent a revolution in durable, sustainable housing. Their exceptional strength, customizability, and eco-friendly attributes make them an ideal choice for modern construction projects. At Zhongda Steel, we combine cutting-edge technology with rigorous quality control to deliver villas that not only withstand the test of time but also offer unparalleled comfort and efficiency. As the demand for resilient, sustainable housing grows, our prefabricated light steel villas stand ready to meet the challenges of tomorrow's construction needs.

FAQs

How long do prefabricated light steel villas typically last?

With proper maintenance, these villas can last 50-100 years or more.

Are prefabricated light steel villas suitable for areas prone to earthquakes?

Yes, our villas are certified to withstand Level 7 intensity earthquakes.

Can these villas be customized for different climates?

Absolutely. We offer various insulation options and finishes suitable for diverse climates.

Is it possible to expand a prefabricated villa in the future?

Yes, the modular nature of our designs allows for relatively easy future expansions.

Choose Zhongda Steel for Your Prefabricated Light Steel Villa Needs

As a leading prefabricated light steel villa manufacturer and supplier, Zhongda Steel offers unparalleled quality, durability, and customization options. Our state-of-the-art factory, with a 60,000-ton annual precision fabrication capacity, ensures rapid delivery and consistent quality. Whether you're a developer seeking efficient housing solutions or a homeowner dreaming of a customized villa, our team is ready to bring your vision to life. Experience the future of sustainable living with Zhongda Steel. Contact us at Ava@zd-steels.com to start your project today.

References

Johnson, L. (2022). "Advancements in Prefabricated Steel Construction Techniques". Journal of Sustainable Architecture, 15(3), 78-92.

Smith, A. & Brown, R. (2023). "Comparative Analysis of Traditional vs. Light Steel Frame Buildings in Seismic Zones". Structural Engineering International, 33(2), 210-225.

Zhang, Y. et al. (2021). "Long-term Performance of Galvanized Steel in Coastal Environments". Corrosion Science, 168, 108595.

Green Building Council. (2023). "Environmental Impact Assessment of Prefabricated Steel Structures". Annual Report on Sustainable Construction.

Davis, M. (2022). "Energy Efficiency in Modern Prefabricated Homes". Energy and Buildings, 255, 111667.

World Steel Association. (2023). "Life Cycle Analysis of Steel in Construction". Industry Report on Sustainable Steel Use.

YOU MAY LIKE