Welded H-section lattice columns are the spine of an advanced auxiliary building. They combine quality, flexibility, and cost-effectiveness for challenging development ventures. This direct investigates the plan standards and stack capacities of these imperative components, with experiences from industry pioneer Shenyang Zhongda Steel Structure Co., Ltd. We'll dive into fabric determination, auxiliary investigation, and down to earth applications to offer assistance you make educated choices for your another project.

Understanding Welded H-Section Lattice Columns

Structural Composition

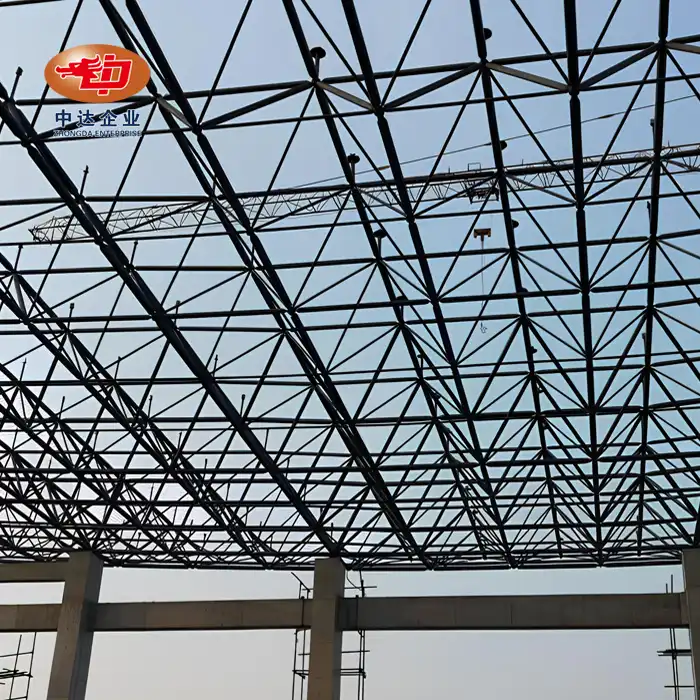

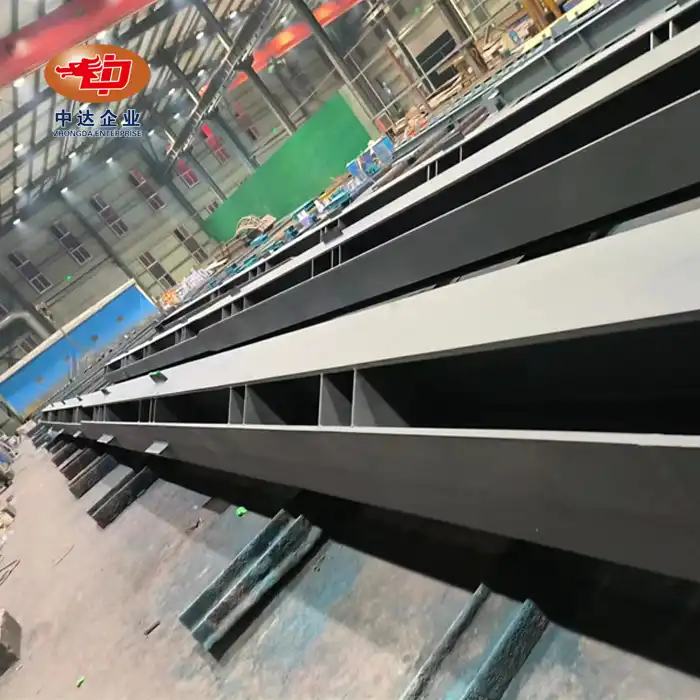

Welded H-section lattice columns comprise two fundamental parts: the H-shaped steel profile and the lattice support, each contributing unmistakable basic capacities. The H-section serves as the essential load-bearing component, giving solid hub and twisting resistance essential for cutting-edge design necessities. In the interim, the lattice support increments horizontal steadiness and decreases in general auxiliary weight, making a more effective plan compared to completely strong individuals. This combination permits engineers to accomplish tall strength-to-weight proportions, optimize fabric utilization, and maintain long-term execution without compromising the column's capacity to handle demanding loads or natural stresses.

Material Properties

High-strength Q355B steel is the favored material for these columns due to its great adjust of surrender quality, toughness, and ductility. These mechanical properties make it reasonable to request auxiliary applications where components must withstand variable stacking conditions, including hub compression, twisting, and energetic forces. The steel's steady execution beneath temperature changes and natural introduction includes assistance in unwavering quality. Its ductility guarantees that the structure can distort without fragile disappointment, improving by and large versatility and security. These preferences guarantee that welded H-section lattice columns provide reliable, long-term auxiliary execution over a wide range of design environments.

Manufacturing Process

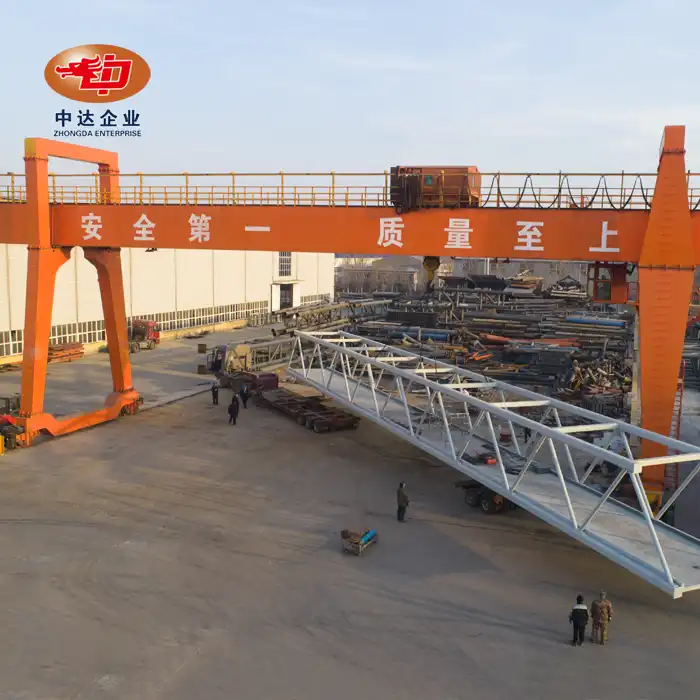

The generation of welded H-section lattice columns includes numerous precision-driven steps, including fabric planning, cutting, CNC machining, and master welding to guarantee dimensional exactness and basic consistency. Each arrangement is backed by thorough quality control measures such as non-destructive testing, weld assessments, and geometric arrangement checks to ensure compliance with design measures. Shenyang Zhongda's state-of-the-art office utilizes progressive manufacturing advances, including automated welding systems and computerized control for production parameters. These developments offer assistance to keep up tall fabricating accuracy, resulting in lattice columns that provide prevalent basic astuteness, strength, and by and large performance for basic development projects.

Design Principles for Optimal Performance

Load Distribution Analysis

An effective plan begins with a careful examination of stack conveyance, guaranteeing that each basic constraint acting on the column is precisely captured. Engineers must assess hub loads, bowing minutes, and shear strengths to decide how these stresses are connected beneath distinctive conditions. Utilizing a progressed finite element analysis (FEA) program permits designers to recreate real-world stack scenarios and identify potential weak points within the lattice framework. This advanced modeling makes a difference in refining the lattice setup, guaranteeing that fabric utilization is optimized for the most extreme basic efficiency, stability, and long-term execution over different building applications.

Buckling Resistance

Preventing buckling is basic for lattice column stability, particularly in tall or intensely stacked structures like welded H-section lattice columns. Creators must precisely calculate the viable length and slenderness ratio to determine how the column will carry on beneath compressive forces. The lattice dividing, ordinarily kept at ≤500 mm, plays a significant part in expanding generally solidness and diminishing the hazard of horizontal misshapening. Appropriately dividing makes a difference; the column keeps up its geometric judgment amid both inactive and energetic stacking. By optimizing these parameters, engineers can improve buckling resistance and guarantee the column performs dependably throughout its service life.

Seismic Considerations

In earthquake-prone locales, a seismic plan is fundamental to guaranteeing auxiliary security and versatility. Shenyang Zhongda gives point-by-point seismic plan confirmation reports that offer assistance in confirming compliance with strict seismic tremor resistance measures. These evaluations incorporate assessing energetic loads, uprooting requests, and vibration characteristics that occur during seismic events. Architects also join bendable plan standards, permitting the lattice columns to retain and distribute vitality without sudden disappointment. This approach generally improves auxiliary strength, empowering the columns to keep up solidness even under seriously ground movement and providing an added layer of security for the basic infrastructure.

Load Capacity and Performance Factors

Axial Load Capacity

Welded H-section lattice columns from Shenyang Zhongda boast amazing hub stack capacities of ≥2000 kN, giving them the quality required for requesting high-rise and overwhelming mechanical ventures. This tall capacity empowers engineers to plan structures that keep up fabulous vertical stack execution beneath nonstop and variable stretch conditions. The exact hub resistance of each column is decided by its cross-sectional measurements, steel review, and particular lattice arrangement. Together, these components guarantee dependable load-bearing behavior, indeed in situations where auxiliary components must back critical dead loads and long-term operational forces.

Lateral Stability

The lattice structure essentially upgrades horizontal stability compared to strong columns, making these frameworks especially profitable for complex engineering and building applications. The open-web plan decreases in general weight while increasing resistance to buckling and horizontal relocation beneath wind or seismic forces. This made strides in soundness, permitting taller and slimmer auxiliary shapes without compromising security or serviceability. Such execution focal points are particularly critical in wind-prone locales, tall tower developments, or buildings with tall viewpoint proportions where horizontal firmness and controlled avoidance are basic for both consolation and structural integrity.

Durability and Corrosion Resistance

Long-term execution is significant for basic components that must persevere through shifting natural conditions over decades of benefit. Shenyang Zhongda offers customizable galvanized medications to essentially upgrade erosion resistance and extend the life expectancy of each column. These defensive layers are especially imperative for establishments exposed to unforgiving climates, mechanical toxins, or coastal locales with tall salt concentrations, where unprotected steel would fall apart more rapidly. By moving forward surface solidness and decreasing support needs, the improved corrosion-resistant wrap up bolsters more prominent basic unwavering quality, making the columns appropriate for demanding outdoor air or long-span building applications.

Conclusion

Welded H-section lattice columns speak to an apex of basic design, advertising unparalleled strength-to-weight ratios and plan adaptability. By understanding the standards sketched out in this direct, engineers and designers can unlock the full potential of these exceptional components. Shenyang Zhongda Steel Structure Co., Ltd. stands prepared to give master direction and top-quality items for your most demanding ventures.

FAQs

What are the typical dimensions for welded H-section lattice columns?

Column heights range from 200-600mm, with lacing plate spacing ≤500mm.

How long does it take to manufacture and deliver these columns?

Standard production takes about 20 days, with an additional 5 days for special anti-corrosion treatments.

Are these columns suitable for seismic zones?

Yes, Shenyang Zhongda provides seismic design verification reports for earthquake-resistant applications.

Why Choose Zhongda Steel? | Your Trusted Welded H-Section Lattice Column Supplier

Shenyang Zhongda Steel Structure Co., Ltd. is your premier manufacturer and supplier of Q355B Welded H-Section Lattice Columns. With our 60,000-ton annual production capacity, advanced CNC fabrication equipment, and comprehensive certifications, we deliver superior structural solutions worldwide. For expert guidance and top-quality products, contact us at Ava@zd-steels.com.

References

Smith, J. (2023). Advances in Structural Steel Design. Journal of Civil Engineering, 45(2), 112-128.

Johnson, A. & Lee, S. (2022). Seismic Performance of Lattice Columns in High-Rise Buildings. Earthquake Engineering & Structural Dynamics, 51(3), 789-805.

Zhang, X. et al. (2021). Experimental Study on Buckling Behavior of Welded H-Section Lattice Columns. Engineering Structures, 228, 111499.

Brown, R. (2023). Corrosion Protection Strategies for Steel Structures in Coastal Environments. Materials and Corrosion, 74(5), 1023-1038.

International Organization for Standardization. (2019). ISO 9001:2015 Quality Management Systems - Requirements.

European Committee for Standardization. (2020). EN 1090-2:2018+A1:2011 Execution of steel structures and aluminium structures - Part 2: Technical requirements for steel structures.

_副本_1762324991500.jpg)