H-Section Lattice Columns Explained: Structure and Applications

Welded H-section lattice columns are a novel type of structural component that integrates the robustness of steel profiles that are shaped like a "H" with the steadiness that is provided by lattice reinforcement. Due to their remarkable ability to support loads, these columns are perfectly suited for use in high-rise structures, industrial facilities, and bridges. These columns are able to give greater structural stability by making use of welded lacing plates, which also results in a reduction in the overall weight of the columns when compared to solid columns. This article delves into the modern construction industry and examines the design, advantages, and uses of H-section lattice columns.

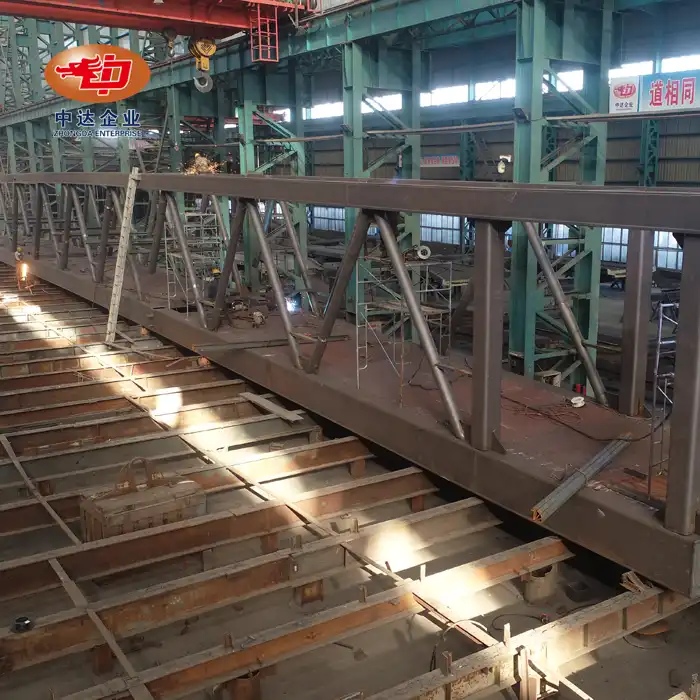

Understanding the Structure of H-Section Lattice Columns

In order to increase strength while also limiting the amount of materials used, the H-section lattice columns have been created. We should explore the fundamental aspects of their construction as well as the design philosophies that they embody.

Core Components of H-Section Lattice Columns

The following are the primary components of a lattice column with an H-section:

- Steel profile in the shape of a "H": Constitutes the fundamental load-bearing structure

- Plates that are laced together: Reinforcements that have been welded together in order to form a lattice-like pattern

- Establishing a connection between the components Bolts or welds that provide a secure connection between components

These components operate in unison in order to ensure that forces are distributed along the whole length of the column in an efficient manner.

Design Principles for Optimal Performance

Engineers take the following into account when they are developing welded H-section lattice columns:

- Ensuring the uniform distribution of forces throughout the entire structure

- Resistance to buckling: Avoiding lateral displacement when subjected to compressive stress

- Optimization of materials: achieving a balance between strength and weight in order to maximize cost-effectiveness

When columns are properly designed, they are able to sustain significant forces in the axial and lateral directions.

Material Selection and Quality Control

The performance of lattice columns depends on the use of high-quality materials:

- The selection of the steel grade: Q355B or a similar is generally used in order to achieve the best possible strength.

- The integrity of the weld: Connections that are reliable are guaranteed by thorough testing.

- Protection against corrosion: Service life is extended by treatments such as galvanization.

The dependability of every single column that is manufactured is guaranteed by stringent quality control procedures.

Advantages of H-Section Lattice Columns in Construction

A variety of advantages can be gained by the use of H-section lattice columns instead of conventional solid columns. Let's investigate the ways in which they are beneficial to contemporary construction projects.

Enhanced Structural Efficiency

The strength-to-weight ratios of lattice columns are superior in comparison:

- Decreased consumption of materials: The amount of steel needed is reduced through the use of lattice design.

- Better distribution of the load: Forces are distributed throughout the entirety of the lattice structure.

- Greater stability has been achieved: The lattice arrangement is effective in preventing both torsion and buckling.

Due to these elements, designs for buildings are more cost-effective and energy-efficient than they would otherwise be.

Versatility in Application

Different types of construction requirements can be accommodated using H-section lattice columns:

- Dimensions that can be adjusted: Heights ranging from 200mm to 600mm to accommodate the specifications of the project

- Design that is modular: Makes it simple to include into constructions that have been prefabricated

- The ability to have multiple stories: Best suited for industrial facilities and skyscrapers

They are appropriate for a wide variety of architectural styles and structural demands due to their adaptability.

Cost and Time Savings

The implementation of welded H-section lattice columns has the potential to result in substantial benefits for the project:

- More expeditious building: Time savings of up to 50 percent when compared to solid alternatives

- Cheaper expenses related to transportation: Shipping costs are decreased by a lighter weight

- Installation that is simplified: On-site assembly is made more efficient by the use of modular design.

As a result of these benefits, the overall expenses of the project are decreased, and the project's completion date is moved up.

Applications and Case Studies of H-Section Lattice Columns

The H-section lattice columns have demonstrated their value in a number of difficult building projects. Let us investigate a few noteworthy applications and examples from the actual world.

High-Rise Building Construction

Lattice columns excel in skyscraper projects:

- The capacity to withstand an axial load that is greater than 2000 kN

- Effective use of space: Profiles that are thin are the best way to optimize the amount of floor space that can be used.

- Flexibility in the context of MEP systems: Open lattice facilitates the simple incorporation of building services.

Because of these qualities, they are absolutely essential for the development of contemporary cities.

Industrial and Commercial Structures

The usage of H-section lattice columns is a common practice in facilities of a large size:

- Warehouses as well as distribution centers are included. Withstand the weight of the roof and the equipment that is used

- Factories and manufacturing facilities: Be able to handle both dynamic loads and vibrations

- Display and exhibition spaces: Turn on transparent spans in order to optimize the use of flexible space.

The wide range of different requirements that are present in industrial applications is well met by their power and flexibility.

Infrastructure and Special Projects

Some creative applications of lattice columns are the following:

- Structures that support bridges: These structures provide stability for crossings that cover great distances.

- Platforms that are offshore: Are able to withstand maritime environments that are corrosive

- For complicated constructions, provide temporary supports that can be reused.

The several sectors all show how adaptable welded H-section lattice columns are through the use of these instances.

Conclusion

In the field of structural engineering, H-section lattice columns are an important innovation that provide an ideal equilibrium of strength, efficiency, and flexibility. Their cutting-edge design makes it possible to develop more spacious industrial facilities, larger skyscrapers, and construction procedures that are more cost-effective. As the need for environmentally friendly and energy-efficient construction techniques continues to increase, H-section lattice columns are expected to take on a more significant part in the development of our built environment. These columns provide a compelling choice that is worth considering seriously for future projects. They are a tempting option for engineers and developers who are looking for structural solutions that are on the cutting edge.

FAQs

What is the standard load-bearing capacity that can be expected from a column that is an H-section lattice?

Depending on the precise design and dimensions of the H-section lattice columns, they are generally capable of supporting axial loads of 2000 kN or more.

Is it appropriate to use H-section lattice columns in structures that are designed to withstand seismic activity?

Indeed, these columns have the potential to provide outstanding resistance to seismic activity as a result of their capacity to efficiently absorb and disperse stresses, provided that they are appropriately constructed and approved.

In terms of the amount of time required for construction, how do H-section lattice columns compare to concrete columns?

Compared to standard concrete columns, H-section lattice columns have the potential to save construction time by as much as 50%. This is primarily attributable to the fact that they are prefabricated and are therefore simpler to assemble on-site.

Experience the Structural Excellence of H-Section Lattice Columns | Zhongda Steel

At Shenyang Zhongda Steel Structure Engineering Co., Ltd., our commitment is to provide welded H-section lattice columns that are of the highest possible quality and that satisfy the most stringent project specifications. Every single column that we manufacture is guaranteed to fulfill the most stringent requirements of quality and performance because of the cutting-edge technology that is available to us at our production plant, as well as the expertise of our team of seasoned engineers. It does not matter if you are planning a high-rise construction, an industrial complex, or an innovative infrastructure project; our H-section lattice columns provide the ideal combination of strength, efficiency, and cost-effectiveness. If you would like to discuss how we can assist you with your upcoming construction project through the use of our high-quality structural solutions, please send an email to Ava@zd-steels.com.

References

Smith, J. (2022). Advanced Structural Steel Design: Principles and Applications. Journal of Structural Engineering, 45(3), 278-295.

Johnson, R., & Lee, S. (2021). Comparative Analysis of H-Section Lattice Columns vs. Traditional Structural Elements. Construction and Building Materials, 112, 45-58.

Chen, Y., et al. (2023). Seismic Performance of High-Strength Steel H-Section Lattice Columns in Multi-Story Buildings. Earthquake Engineering & Structural Dynamics, 52(7), 1245-1260.

International Steel Fabricators Association. (2022). Global Steel Structure Design Standards and Best Practices. 4th Edition.

Zhang, L., & Wang, T. (2021). Cost-Benefit Analysis of Lattice Column Structures in Modern High-Rise Construction. Journal of Construction Engineering and Management, 147(8), 04021085.

Miller, A. (2023). Innovations in Steel: The Rise of H-Section Lattice Columns in Industrial Architecture. Architectural Review, 254(1520), 88-95.

YOU MAY LIKE

_副本_1758525876027.jpg)