Installing steel box girders on long-span bridges is a complicated set of technical steps that include careful planning, advanced lifting methods, and strict quality control. When compared to regular I-beams, these hollow structural parts with fully welded box sections offer better strength distribution and twisting resistance. Usually, the installation process starts with 12–30 meter prefabricated segments that are brought to the construction site and put together using specialized methods like incremental launching, balanced cantilever construction, or launching gantries. This cuts down on construction time by about 50% while still making sure the structure stays strong for spans up to 420 meters.

Understanding Steel Box Girder Basics and Design Principles

Contemporary bridge building relies heavily on the exceptional performance qualities of steel box girders, which are a big step forward from older structure systems. These hollow rectangular or trapezoidal parts are made to be very stiff and hold a lot of weight, which makes them perfect for difficult long-span uses.

Structural Configuration and Material Specifications

Full-welded box construction is at the heart of steel box girders; this gives them better structural performance than standard I-beam layouts. For main structural parts, the primary material standard calls for Q345D steel with a minimum yield strength of 345MPa. For critical joints, the specification calls for Q420D steel to make them last longer. The choice of materials makes sure that the best performance is achieved under heavy loads while keeping costs low.

Design Flexibility and Customization Options

Modern steel box girder systems are very flexible because they can be designed with different cross-sections. The structure's height can be changed from 1.25 meters to 8 meters, which lets engineers make the best design for the span and load conditions that are needed. Modern choices for corrugated steel webs can cut weight by up to 20% without affecting the structure's strength. This makes building projects with single spans of up to 420 meters cheaper.

When these design principles are combined with current fabrication methods, buildings are made that are very good at distributing load, keeping their shape, and adapting to changing environments. Steel box girders are the best option for large bridge projects all over the world due to their better weight-to-strength ratio, increased longevity thanks to cutting-edge corrosion-resistant treatments, and ease of erection.

Step-by-Step Installation Process of Steel Box Girders on Long-Span Bridges

To make sure safety and structural stability, installing steel box girders on long-span bridges needs to be carefully planned and carried out. There are several important steps in the process, and each one needs specialized knowledge and tools to work well.

Pre-Installation Planning and Site Preparation

A thorough site inspection and confirmation that the base is ready are the first steps to a successful installation. Engineering teams do thorough studies to make sure that the bearing capacity, alignment accuracy, and ease for big equipment are all correct. The foundations need to be ready to handle the heavy loads that will be put on them during the building process, and temporary support structures need to be placed in a way that keeps the structure stable while it is being built.

Transportation and Handling Logistics

To move premade steel box girder pieces, you need special moving equipment made for large loads. For safe highway transport, the parts, which are usually between 12 and 30 meters long, need special trailers and escort cars. Advanced transportation planning makes sure that delivery times are in sync with building milestones, and that traffic problems are kept to a minimum so that everyone stays safe.

Erection Methods and Assembly Techniques

During the actual installation, different complex erection methods are used based on the conditions of the spot and the needs of the project. In current building, these are the main methods used:

- Incremental Launching: With this method, finished bridge pieces are pushed across temporary supports using hydraulic jacks. This lets work continue without stopping traffic below. This method works especially well for highway overpasses and places in cities where entry is limited.

- Balanced cantilever construction: pieces are added equally to keep the structure balanced while it is being built, starting from where the piers are. This method cuts down on the need for temporary supports while giving great control over the final shape and building tolerances.

- Launching Gantry Systems: Specialized gantries that span multiple supports make it possible to place concrete pieces precisely. These systems are very accurate and can work with different beam lengths while keeping the quality of the job the same.

When compared to traditional methods, these new techniques often save 50% of the time needed for building while still meeting the highest safety standards. Modern tools allow for very accurate control, which makes sure that the end angles meet very strict engineering standards.

Technical Challenges and Solutions in Long-Span Steel Box Girder Installation

Building a long-span bridge is a unique engineering task that needs creative solutions and close attention to how the structure acts while it is being put together. Understanding these problems helps project teams come up with good ways to deal with them.

Structural Stability and Load Management

One of the most important parts of long-span installation for steel box girder is keeping the structure stable against deflections, shaking, and dynamic loads while it is being built. Temporary support systems need to be carefully designed so that they can adapt to changing load patterns as new parts are added. Modern tracking systems keep an eye on deflections and stress levels all the time, so engineers can make changes right away if they need to.

Corrosion Protection and Environmental Considerations

Long-term reliability depends a lot on how well corrosion protection methods are used during installation. When you combine galvanizing with special spray coats, you get two layers of protection that make the product last longer than 30 years, even in tough environments. When and how the covering is applied are two very important factors that have a direct effect on its long-term performance.

Because of things in the environment like wind loads, changes in temperature, and earthquakes, certain design elements and construction procedures need to be used. Modern steel box girders have details that make them immune to fatigue and earthquake isolation features that make sure they stay safe and work well for a long time.

Procurement Insights: Selecting and Sourcing Steel Box Girders for Your Project

When planning how to buy steel box girders, it's important to think about a lot of different factors that can affect the project's success, its ability to stay on schedule, and its total cost-effectiveness. Understanding these factors helps you make smart choices during the seller selection process.

Key Procurement Considerations

Steel tonnage needs, the difficulty of special construction, and manufacturing wait times all have a big impact on project timelines and budgets. For projects that need custom shapes or configurations, production schedules usually need to be extended. This means that early contact with suppliers is crucial for meeting building goals.

Supplier Evaluation and Quality Assurance

Projects that go well are built on relationships with reliable suppliers. Technical skills, certification compliance, and past achievement records should all be part of the evaluation factors. Suppliers with ISO 9001, 14001, 45001, EN 1090 compliance, and other specialty licenses show they are committed to quality standards that are important for building important infrastructure.

Global supplier landscapes offer a wide range of choices, but overseas shipping of large structure parts like steel box girder needs specific transport knowledge. For a smooth project execution, thorough delivery planning includes port handling skills, overland transportation routes, and site entry needs.

Zhongda Steel: Your Trusted Partner for Premium Steel Box Girder Solutions

Shenyang Zhongda Steel Structure Engineering Co., Ltd. has been making steel box girders for 20 years and can give custom solutions that mix new ideas with strict quality control. We are a widely recognized leader in precise steel solutions. We were founded in 2004 and have our main office in the Shenyang Economic-Technological Development Zone.

Advanced Manufacturing Capabilities

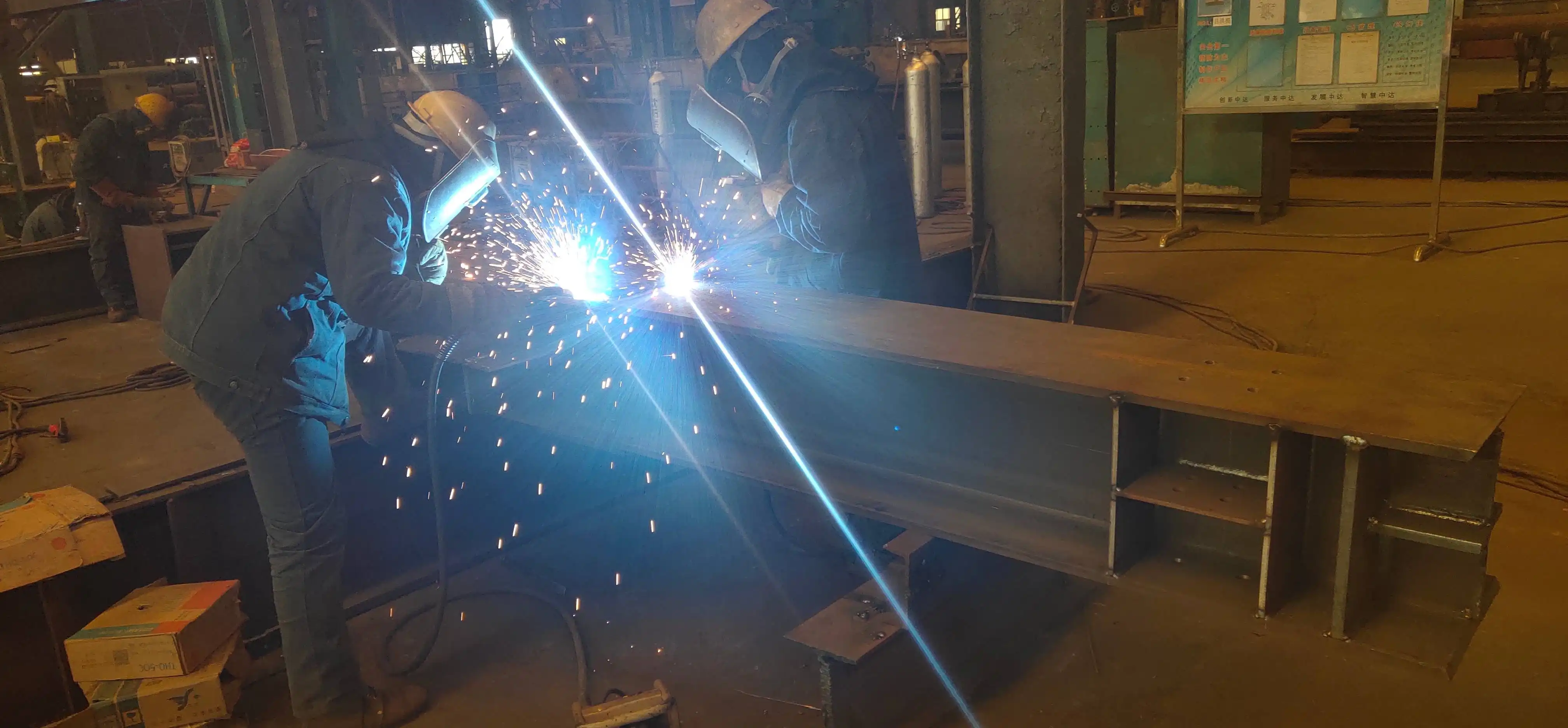

Our state-of-the-art 120,000 m² manufacturing plant can make 60,000 tons of products every year, thanks to advanced CNC ultra-thick plate cutting technology that can achieve ±0.2mm accuracy. The factory has fully automatic welding lines and quality control systems that make sure the products are always of the highest standard. Our BIM-driven prefabrication method makes it easier to integrate designs and speeds up the delivery of projects.

Product Excellence and Innovation

We are experts at designing fully welded box sections out of high-strength Q345D and Q420D steel to give the best performance in tough situations. Our engineering team works closely with clients to create unique solutions that include the ability to change cross-sections, the best use of curved steel webs, and the latest anti-corrosion treatments. Using our own -60°C Weathering Steel Anti-corrosion Technology makes sure that the steel will last a very long time in tough settings.

Custom fabrication, advanced engineering consulting, and full lifetime support, which includes inspection and upkeep services, are some of the things we do best. As a team effort, we are proud to have completed steel box girders for important projects like the 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge and many other foreign infrastructure projects in Russia, Australia, and Vietnam.

Conclusion

Putting in steel box girders on long-span bridges is a complicated engineering process that needs skill, accuracy, and relationships that you can count on. Technical standards, installation methods, and buying issues must be understood by project teams in order for them to make decisions that improve performance and reduce costs. Bridge building projects are more likely to be successful when they use improved materials, new ways to make things, and tried-and-true ways to put them together. As the world's need for infrastructure grows, high-quality steel box girder suppliers play an even more important part in making sure projects are successful.

FAQs

What are the usual wait times for steel box girders that are made to order?

Customized steel box girders usually have lead times between 12 and 20 weeks, but this depends on how complicated the job is, what materials are needed, and how much can be made. Customized configurations or non-standard sizes may need more time for planning and production on certain projects. Getting suppliers involved early on in the planning process helps make sure that shipping times are optimized to fit with building milestones.

What is the difference between steel box girders and concrete girders when it comes to maintenance?

If you protect steel box girders from corrosion properly, they only need to be inspected and maintained every 15 to 20 years. On the other hand, concrete girders may need to be fixed every 10 to 15 years for cracks, spalling, or reinforced corrosion. These days, steel girders have special coats that protect them. They can last more than 30 years with little upkeep, which saves money over the life of the building.

What are the best ways to protect against rust in seaside areas?

Coastal areas need strong rust protection methods that use both hot-dip galvanizing and special topcoat applications. When used in salt-air settings, double protection methods with zinc-rich primers and moisture-resistant topcoats work best. Every 5 to 7 years, regular inspections make it possible to find problems early and fix them so that defensive systems last for a long time.

Partner with Zhongda for Your Next Bridge Project

Zhongda Steel has the best steel box girder options in the business and is ready to help you build your long-span bridge. We are the best steel box girder supplier for tough building projects because we have advanced production skills, scientific knowledge, and a track record of successful projects. Whether you need standard setups or solutions that are specifically designed for your needs, our team can help you from the beginning of the planning process to the final delivery.

Procurement managers, engineers, and project planners are welcome to talk to us about how our knowledge of steel box girders can help your next project. Are you ready to talk about your personal needs? Email Ava@zd-steels.com to set up a meeting with our engineering team and find out why top builders around the world choose Zhongda for their most important building projects.

References

American Association of State Highway and Transportation Officials. "AASHTO LRFD Bridge Design Specifications: Steel Box Girder Construction Guidelines." 8th Edition, Transportation Research Board, 2017.

Chen, W.F. and Duan, L. "Bridge Engineering Handbook: Superstructure Design - Steel Box Girder Systems for Long-Span Applications." CRC Press, 2014.

European Committee for Standardization. "EN 1993-2 Eurocode 3: Design of Steel Structures - Steel Bridges Part 2: Steel Box Girder Installation Methods." Brussels, 2019.

Federal Highway Administration. "Steel Bridge Design Handbook: Box Girder Construction and Installation Procedures." U.S. Department of Transportation, Publication No. FHWA-HIF-16-002, 2015.

International Association for Bridge and Structural Engineering. "Structural Engineering Documents: Long-Span Steel Box Girder Bridges - Design and Construction Guidelines." IABSE, Zurich, 2018.

Troitsky, M.S. "Cable-Stayed Bridges: Theory and Design - Steel Box Girder Implementation in Modern Bridge Construction." 3rd Edition, BSP Professional Books, 2016.