To figure out the tensile strength of structural steel, normal tensile tests must be used to find the highest stress the material can handle before breaking. For this test, you need to look at mill test papers, know about ASTM and EN grade standards, and think about things like chemical make-up and heat treatment. The right testing makes sure that your structural steel meets the needs of the project and safety standards. This is important for building, manufacturing, and infrastructure projects where the dependability of the materials affects the structure's strength and performance over time.

Understanding Structural Steel Tensile Strength

The tensile strength of steel tells you how much stress it can take before it breaks when it is pulled apart. This mechanical trait is very different from ultimate strength, which shows the highest stress before a break, and yield strength, which shows the point at which permanent displacement starts.

Key Factors Influencing Steel Tensile Properties

Chemical make-up is a very important factor in determining tensile properties. The amount of carbon in a material directly affects its strength. Higher carbon ratios usually increase tensile strength but may decrease flexibility. Manganese, silicon, and chrome are examples of alloying elements that improve mechanical qualities in a number of different ways.

Heat treatment processes significantly impact final tensile values. During production, controlled cooling rates form microstructures that make the best use of strength-to-weight ratios. Modern steelmakers use careful thermal management to make sure that all of their production batches have the same tensile qualities.

Industry Standards and Grade Classifications

The ASTM standards give complete guidelines for checking tensile strength. Tensile strengths for Grade A572 range from 65,000 to 80,000 PSI, and those for Grade A992 are usually at least 65,000 PSI. European EN standards set similar standards that make sure that global projects can work together.

When procurement experts understand these classes for structural steel, they can choose the right grades for different uses. When building a bridge, the tensile needs are different from when framing a warehouse. This makes grade selection very important for the success of the job.

Methods to Evaluate Structural Steel Tensile Strength

Multiple testing methods give you a lot of options for figuring out a material's tensile strength. Each method has its own benefits and can be used to meet the needs of a particular project and follow quality assurance rules.

Standard Tensile Testing Procedures

Tensile testing in a lab is still the best way to get an exact reading on strength. For this method, standard specimens are machined from steel samples and then put under controlled stress until they break. The stress-strain graph that is made shows important information like the final tensile strength, the yield strength, and the elongation rates.

Universal testing machines that are set to worldwide norms are used in testing labs. These tools slowly increase the loads they apply while recording how much the object deforms. This creates accurate stress-strain relationships that show how a material behaves when it is under tension.

Non-Destructive Testing Alternatives

Ultrasonic testing gives us useful information about the structure inside steel without hurting the material. This method finds changes in the microstructure that affect the tensile qualities of a material quickly, making it useful for large-scale checks.

There are proven models that show a link between hardness testing and tensile strength. Portable hardness tools let you test in the field, which helps with quality control during the building process. Even though these methods can't fully replace tensile tests, they are still useful for screening materials before buying something.

Predictive Modeling and Software Solutions

Chemical research and processing factors are used by advanced computer models to guess the tensile properties. These tools speed up the process of choosing materials by predicting how they will work before they are actually tested. This cuts down on the time needed to buy things while still keeping quality standards.

By looking at trends in past data, machine learning systems are helping to predict tensile strength for materials like structural steel more and more. These technologies improve the efficiency of buying while also giving early reviews for processes that qualify materials.

Comparing Structural Steel Tensile Strength with Other Materials

To choose the right material, you need to know a lot about how different choices handle tension stress. When compared to other building materials, steel consistently has better tensile properties. This makes it the best choice for demanding structure uses.

Steel versus Traditional Construction Materials

Concrete has a high compression strength but a low tensile strength, so it usually needs to be reinforced for tension-bearing uses. Wood has average tensile strength, but it changes a lot depending on the species, the direction of the grain, and the amount of moisture in the wood. Because of these problems, steel is better for uses that need reliable tension performance.

Aluminum alloys have a good tensile strength and great corrosion protection, but their exact strength numbers are usually lower than steel's. When comparing strength to weight, aluminum is better in some situations, but steel is still better when there is a lot of stress.

Performance and Cost Considerations

The initial cost of materials is only one part of the overall economics of a job. Steel's better tensile qualities allow for better structure designs with less material, which often makes up for its higher unit costs. Steel is more valuable when you think about its lifecycle, which includes things like upkeep needs and longevity.

Fabrication compatibility has a big effect on how much the whole job costs. Steel's ability to be welded and machined makes building more efficient, requiring less work than other materials that need more complicated ways to join them.

Practical Considerations When Procuring Structural Steel Based on Tensile Strength

To successfully buy things like structural steel, you need to use organized methods that make sure the quality of the materials and improve the results of the job. Knowing what your provider can do and how they make sure quality is done can help you avoid costly delays and performance problems.

Supplier Selection and Certification Requirements

Certified providers keep quality management systems that are in line with ISO 9001 standards. This makes sure that production methods are always the same and that the tensile properties are always reliable. These certificates show that you are dedicated to quality control and making things better all the time.

Mill test papers are important proof that the tensile strength requirements have been met. The results of chemical analyses, data from mechanical tests, and information on how to trace materials back to particular production runs are all in these papers. Before taking deliveries, people who work in procurement should make sure that the certificates are real and full.

Quality Assurance and Testing Protocols

Third-party testing services let you check the claims made by a seller without having to go through the source. This is especially helpful for important applications that need higher quality assurance. These services help with risk management strategies and give neutral opinions on tensile qualities.

When something comes in for inspection, it should be looked at visually for surface flaws, its dimensions should be checked, and all paperwork should be read over. These methods find possible problems before the building materials are used, which stops problems later on and slows the project.

Logistics and Material Handling Considerations

The tensile qualities of steel are kept during project steps by storing it in the right way. Controlling moisture stops rust that could weaken the structure, and making sure there is enough support stops it from deforming during handling.

How things are transported affects their state when they arrive at their destination for structural steel. Professional transportation companies know how to handle steel safely and use the right tools to keep damage to a minimum during loading and unloading.

Zhongda Steel: Your Trusted Partner for High-Quality Structural Steel Solutions

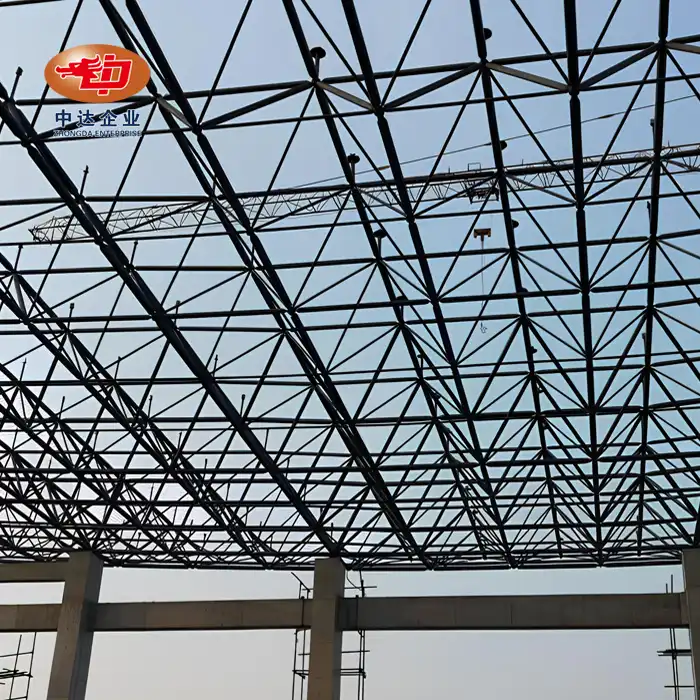

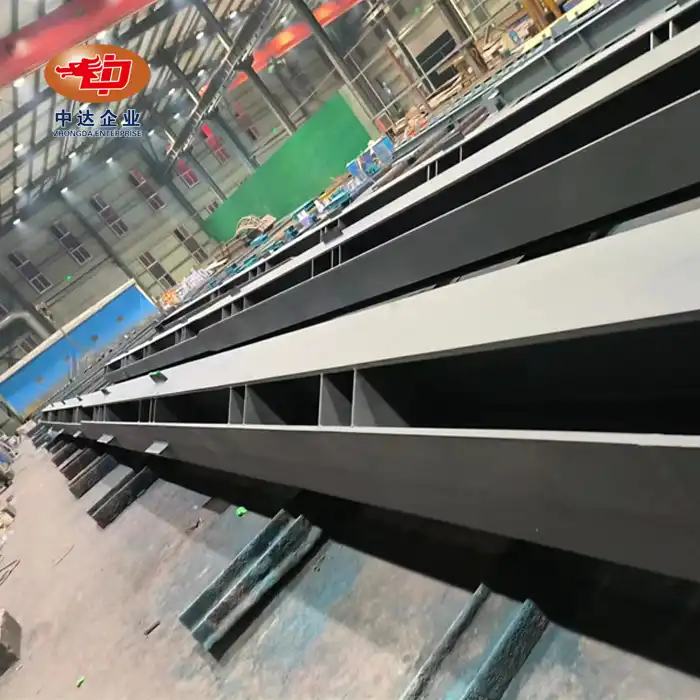

Our state-of-the-art 120,000 m² site in the Shenyang Economic-Technological Development Zone is where Zhongda Steel operates. We are recognized as a world leader in precision steel solutions. We have been dedicated to engineering success since our founding in 2004. We have a number of quality certifications, such as ISO 9001, ISO 14001, OHSAS 45001, and EN 1090.

Advanced Manufacturing Capabilities

Our high-quality manufacturing includes BIM-driven prefabrication technologies that make sure every part is made precisely. The building can hold up to 60,000 tons per year, which means it can handle big jobs while still meeting the highest quality standards. We can cut ultra-thick plates with accuracy of ±0.2mm, which shows the technical know-how that makes us stand out in the business.

Our dedication to new ideas is shown by our groundbreaking -60°C Weathering Steel Anti-corrosion Technology. Because of this special technology, steel buildings can stand up to harsh environmental conditions. This makes our goods perfect for tough jobs like Arctic infrastructure projects.

Global Project Experience and Client Trust

We have worked on some of the most important projects in the world, from bridges across the Arctic in Russia to buildings for mining equipment in Australia and industrial hubs in Vietnam. Our scientific skills and dependability are backed up by relationships with leaders in the field, like China Railway, CSCEC, and BMW.

Our all-around method, which includes knowing a lot about the materials, being very careful when making things, and being available to help customers right away, helps every job. This all-in-one service plan makes sure that clients get the best options for their tensile strength needs and project requirements.

Conclusion

To figure out the tensile strength of structural steel, you need to know a lot about how to test it, what its qualities are, and how to buy it the right way. With this information, you can make smart choices that will ensure the project's success while also maximizing performance and lowering costs. The right way to evaluate includes lab tests, checking the supplier's license, and quality control procedures that make sure the purity of the materials is maintained throughout the building process. Procurement professionals can easily choose steel products that meet strict structural needs and support long-term project goals by using methodical methods to tensile strength assessment.

FAQs

How strong is structural steel when it is pulled apart?

Different grades and specifications of structural steel have different tensile strengths. The range is from 58,000 to 80,000 PSI (400 to 550 MPa). Common grades, like ASTM A572 Grade 50, have tensile strengths of at least 65,000 PSI. For certain uses, high-strength grades can go over 100,000 PSI.

How often should tests for tensile strength be done during procurement?

How often you test varies on the needs of the job and the amount of material you have. According to industry norms, each output batch or heat lot needs to be tested. For bigger jobs, you may need to follow more testing procedures. For smaller orders, you can usually count on mill test certificates from certified suppliers who already have quality systems in place.

What can change the tensile strength of steel from one batch to the next?

Tensile properties can be different between runs because of changes in chemical makeup, heat treatment, and the way the product was made. Final strength values are affected by even small changes in the amount of carbon present or the rate at which the material cools. Reliable providers keep tight controls on the process to keep these differences to a minimum and make sure that performance is always the same.

Partner with Zhongda for Superior Structural Steel Solutions

Zhongda has a lot of experience making structural steel, and they also have advanced testing tools and full quality assurance. Our expert team gives you thorough paperwork on tensile strength and manufacturing support that is made to fit the needs of your project. We know how important it is for materials to be reliable in difficult situations because we've worked with clients around the world in the building, infrastructure, and industrial sectors. Are you ready to talk about your wants for a structural steel supplier? Get in touch with our experts right away by emailing Ava@zd-steels.com to find out how our precision steel solutions can help your next project succeed.

References

American Society for Testing and Materials. "Standard Test Methods for Tension Testing of Metallic Materials." ASTM E8/E8M-22. West Conshohocken: ASTM International, 2022.

European Committee for Standardization. "Hot Rolled Products of Structural Steels - Technical Delivery Conditions." EN 10025-2:2019. Brussels: CEN, 2019.

Salmon, Charles G., and John E. Johnson. "Steel Structures: Design and Behavior." 5th Edition. Upper Saddle River: Pearson Education, 2009.

American Institute of Steel Construction. "Steel Construction Manual." 15th Edition. Chicago: AISC, 2017.

Bhadeshia, H.K.D.H., and Robert Honeycombe. "Steels: Microstructure and Properties." 4th Edition. Oxford: Butterworth-Heinemann, 2017.

International Organization for Standardization. "Steel and Steel Products - Location and Preparation of Samples and Test Pieces for Mechanical Testing." ISO 377:2017. Geneva: ISO, 2017.