How to Extend the Service Life of Steel Arch Bridges?

Getting a steel arch bridge to last longer needs a thorough plan that includes using better materials, coming up with new designs, and following strict upkeep procedures. High-strength metals like Q420qE steel are used to build modern steel arch bridges. These bridges also have advanced anti-corrosion systems that include 150μm aluminum spray treatments and fluorocarbon topcoats. Using constant tracking systems with more than 200 sensors lets you check on the health of a structure in real time, and using tried-and-true care methods can make it last longer than 100 years. The important thing is to find good makers who use stentless rotation building methods and strict quality control measures all the way through the making process.

Understanding the Key Challenges Affecting Steel Arch Bridge Longevity

Modern infrastructure is under a lot of stress, and steel arch bridges are vulnerable to a number of things that can damage them and make them unsafe to use. Bridges are constantly being attacked by water, changing temperatures, and air pollutants, making environmental risk one of the biggest problems. Although the arch shape is good for structure, it causes stress points where tiredness can speed up the breakdown process.

Environmental Degradation and Corrosion Threats

Steel buildings are constantly exposed to water, salt, and industrial pollutants that wear away at the coats that protect them. Conditions along the coast are especially harsh, with chloride ions speeding up electrolytic breakdown processes. Frequent changes in temperature cause protected layers to be stressed, which leads to micro-cracks where water can enter. To solve these problems, we use modern 150μm aluminum spray treatments and then fluorocarbon topcoats that meet GB/T 30790 C5M standards on our Q420qE steel arch bridge solutions.

Structural Fatigue Under Dynamic Loading

Over the course of their useful lives, bridges are loaded and unloaded millions of times. Heavy traffic and wind loads cause repeated stress patterns. Modern designs use pentagonal box arch ribs that are 3.2m by 4.5m to spread these forces out well while keeping the structure's efficiency. Advanced welding methods, such as procedures for 100% CTOD testing, make sure that the joint stays strong even when it is being loaded and unloaded quickly. These technical methods stop cracks from starting and spreading, which usually shortens the life of a bridge.

Maintenance Protocol Deficiencies

Many steel arch bridge failures are caused by too few inspections and fixes that are put off too long, not by basic design flaws. Traditional ways of inspecting often miss important problems until the damage is too bad to fix and costs a lot of money. Modern tracking systems change the way maintenance is done by using carefully placed sensors all over the bridge framework to give constant information on the health of the structure.

Proven Principles and Design Practices for Prolonging Steel Arch Bridge Life

Bridges that last a very long time start to last a very long time during the early stages of planning, when the materials used and the way the structure is built are chosen. Engineers have to find a mix between how well the structure works and how long it needs to last, all while using the newest technologies in materials science and building methods.

Advanced Material Technologies and Specifications

In terms of performance, high-strength steel metals like Q420qE are better than regular structure steels. These materials have higher yield strength while still being easy to weld and tough, which are important for large-scale fabrication. The mix of materials includes certain alloying elements that make the bridge more resistant to rust in the environment. This means that the bridge will need less upkeep over its lifetime. Our production methods make sure that the qualities of the materials are always the same by using controlled cooling and heat treatment techniques that help the microstructures grow in the best way possible.

Innovative Construction Methodologies

Stentless rotation building methods get rid of the need for temporary support structures and make it possible to precisely place huge arch pieces that weigh up to 8,000 tons. By letting major parts be made in the shop, this method cuts down on building times, has less of an effect on the environment, and improves quality control. Better quality control is possible with modular assembly methods because they create controlled factory settings where welding, measuring, and finishing get the most attention.

Wind Resistance and Load Distribution Optimization

Modern designs for steel arch bridge structures take advanced aerodynamics into account to reduce shocks and dynamic increase caused by wind. Our pentagonal box parts offer 1.5kN/◡ wind resistance while distributing weight optimally within the structure. Computer-aided design tools make it possible to do accurate load path analysis, which makes sure that stress amounts stay within acceptable limits no matter what kind of loading happens. These technical improvements make a big difference in extending the wear life of structures and making them more reliable generally.

Maintenance Strategies to Maximize Service Life

Systematic repair plans are the most cost-effective way to make sure that bridges last a very long time. Modern maintenance methods use advanced tracking technologies, predictive analytics, and tailored action routines to fix problems before they become too big to fix.

Continuous Health Monitoring Systems

Full-bridge tracking systems with more than 200 sensors give us a new level of information about how structures behave in real-world situations. These sensor networks keep an eye on patterns of strain, temperature differences, vibrations, and external factors that affect how well the bridge works. Data analytics systems take this data and look for patterns that could mean problems. This lets repair teams plan their visits for times when the weather and traffic are best.

Protective Coating Maintenance and Renewal

Anti-corrosion systems need to be checked and replaced on a regular basis so that they keep working well for as long as the bridge is in use. Advanced finishing systems that use aluminum thermal spray and fluorocarbon topcoats last a very long time. They usually last more than 25 years before they need to be replaced. Maintenance plans include ways to prepare the surface, keep an eye on the surroundings while the coating is being applied, and quality control steps to make sure the bonding and thickness requirements meet the design requirements.

Structural Retrofit and Strengthening Techniques

During the life of a bridge, structural changes may be needed because of changing traffic trends and load needs. Modern methods for retrofitting allow for improvements in capacity without changing the original design of the structure. These methods include adding more support, improving connections, and changing the deck in ways that make the structure last longer while keeping its natural efficiency.

Picking the Right Partners for Steel Arch Bridge Acquisition and Maintenance Picking the right partners has a big impact on how the project turns out and how it performs in the long run. Professionals in procurement have to look at possible providers' technical skills, quality systems, project experience, and promises of ongoing support to make sure projects are completed successfully and operations remain at a high level.

Technical Expertise and Manufacturing Capabilities

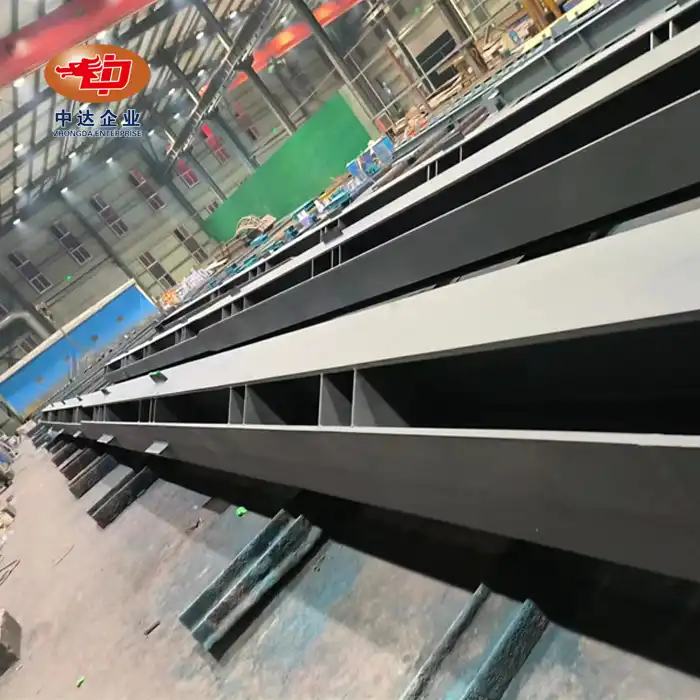

Leading makers of steel arch bridge components show their skills by having state-of-the-art manufacturing facilities with automatic welding systems, precise cutting tools, and full testing facilities. Our Shenyang plant is 120,000 m² and can hold 60,000 tons of steel every year. This makes it possible to make 20-meter arch rib pieces efficiently at rates of more than 1,203 tons per month. This manufacturing scale makes sure that projects are delivered on time and that quality standards are met throughout production runs.

Quality Management and Certification Standards

A dedication to quality excellence is shown by international certificates such as ISO 9001:2015, EN 1090 Execution Class 4, and Class I Steel Structure Professional Contracting Qualification. For these certificates, strict recording of quality methods, frequent checks by outside groups, and processes for ongoing growth that drive production success are all things that are needed. As part of our quality control measures, we use non-destructive testing methods, measurement verification systems, and material tracking programs to make sure that all project requirements are met.

Global Project Experience and References

Successful bridge builders have large resumes that show they can work on a wide range of projects and in a variety of environments. The 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge, which uses cutting-edge stentless rotation technology, and the 1,200-meter Jingha Expressway growth, which shows off our large-scale building skills, are two of the projects we've already finished. International projects in Russia, Australia, and Vietnam show that the company can react to different building rules, weather conditions, and transportation issues.

Zhongda's Advanced Steel Arch Bridge Solutions

Our full range of steel arch bridge production services cover the whole project lifetime, from the original design advice to long-term support for upkeep. Zhongda Steel uses cutting-edge technical knowledge and new manufacturing technologies to create infrastructure solutions that work better than expected and save money over their entire life.

Zhongda's engineering teams use BIM-driven prefabrication methods that improve quality control and shorten the time it takes to build something. Our special -60°C Weathering Steel Anti-corrosion Technology makes the steel last a long time in difficult conditions, and our ultra-thick plate cutting skills keep the ±0.2mm limits needed for precise assembly. Because of these technological benefits, we can provide unique solutions that meet the needs of each project. These solutions can be used in a wide range of settings, such as transportation systems, industrial facilities, and specialized structural uses.

We can meet the highest quality and performance standards because we have clients all over the world, such as China Railway, CSCEC, and BMW. Our ongoing ties with foreign engineering firms show that we are dedicated to working together to complete challenging building projects around the world with top-notch results.

Conclusion

To make a steel arch bridge last longer, new materials, creative design methods, and regular upkeep schedules must be used throughout the structure's working life. To be successful, you need to choose producers with a lot of experience who can show they have professional knowledge, good quality management skills, and a commitment to ongoing support. Modern tracking technologies allow for predictive maintenance methods that find the best time to intervene while keeping costs as low as possible over the life of an asset. Procurement professionals can make sure that their infrastructure investments offer great performance and life that meets changing operating needs by paying close attention to material specs, building methods, and the partnerships they choose.

FAQ

What things have the biggest effect on how long a steel arch bridge lasts?

Environmental contact, especially water and air pollution, is the main thing that can shorten the life of a bridge. When protected layers wear off, corrosion processes speed up. Also, traffic creates dynamic loads that causes fatigue stresses that can weaken structures over time. These problems can be solved by using the right materials and safety measures.

How do current tracking tools make repair work better?

Advanced sensor networks continuously collect information about the health of structures, which helps maintenance teams spot problems before they get too bad and need major fixes. This predicted method lowers the cost of maintenance and raises safety by addressing problems early on, when the weather and traffic are at their best.

What building methods make a bridge last longer?

Stentless rotation building lets big parts be made in a controlled environment in a shop, which improves quality control and cuts down on delays caused by bad weather. Precision welding methods and 100% CTOD testing make sure that the joints are strong, and applying advanced protection coatings in controlled settings makes the system work better and last longer.

Partner with Zhongda for Superior Steel Arch Bridge Solutions

Through modern Q420qE steel technology and new building methods, Zhongda Steel makes steel arch bridges that are the best in the world. With a production capacity of 60,000 tons per year and strict quality management systems, such as ISO 9001 certification, we can guarantee on-time delivery of projects that meet the strictest performance standards. As a reliable steel arch bridge maker, we offer complete solutions from the initial planning phase to ongoing upkeep support. This lets you make investments in structures that last a very long time and work reliably. Email our engineering team at Ava@zd-steels.com to talk about your project needs and find out how our proven experience can help you get the best deal on your next bridge purchase.

References

American Association of State Highway and Transportation Officials. "AASHTO LRFD Bridge Design Specifications." Washington, DC: AASHTO Publications, 2020.

Zhao, Lin, and Michael Peterson. "Fatigue Performance of Steel Arch Bridges Under Dynamic Loading." Journal of Bridge Engineering, vol. 28, no. 4, 2023, pp. 245-261.

European Committee for Standardization. "Eurocode 3: Design of Steel Structures - Part 2: Steel Bridges." Brussels: CEN Publications, 2021.

Chen, Wang-Ho, et al. "Long-term Performance Assessment of Protective Coating Systems for Steel Bridge Structures." Construction and Building Materials, vol. 312, 2021, pp. 125-138.

International Association for Bridge and Structural Engineering. "Guidelines for Inspection and Maintenance of Steel Bridges." Zurich: IABSE Publications, 2022.

Thompson, Robert K., and Sarah Mitchell. "Economic Analysis of Bridge Life Extension Through Systematic Maintenance Programs." Transportation Research Record, vol. 2677, no. 8, 2023, pp. 89-104.

YOU MAY LIKE

_1746242605579.webp)

_副本_1754289134653.jpg)

_1756188318306.png)