The making and building of steel truss bridges are a big part of modern infrastructure development because they combine exact engineering with great manufacturing. People who work on bridge projects, like procurement professionals, engineers, and building contractors, can make good choices if they understand these important steps. From the beginning of the planning process to the end of the installation, every step requires close attention to safety and quality, as well as following every detail of the plan. Modern heavy-duty steel truss bridges use new materials, like ASTM A709 Gr.50 steel, and new protective coats to make sure they work for decades in a wide range of weather conditions.

Understanding Steel Truss Bridge Fabrication: Foundational Principles

Making a steel truss bridge means taking unrefined steel and making perfectly designed parts that are ready to be put together. This complicated process needs a lot of knowledge about material properties, structural mechanics, and fabrication methods that make sure the best performance under different load situations.

Structural Design Fundamentals

The Warren and Pratt truss configurations are the most widely used designs for building bridges in recent times. Warren trusses have lateral parts that take turns being in tension and compression. This lets them efficiently spread the weight over distances from 30 to 150 meters. Pratt trusses have vertical and lateral parts. These trusses work better for highways that need to support up to 100 tons.

Choosing between these settings relies on the needs of the project, such as span length, expected traffic loads, and environmental conditions. Engineers need to carefully study deflection patterns, stress hotspots, and load lines in order to make structures more efficient and use less material at the same time.

Material Selection and Properties

ASTM A709 Gr.50 steel has great strength-to-weight ratios that are useful for very tough uses. This high-performance metal mix has a yield strength of at least 50 ksi, and its Z35 Z-direction features keep it from tearing along layers when welding. Because of its high ductility and fracture toughness, the material is great for dynamic loading conditions that are typical in highway and railway uses.

Good steel suppliers give mill certificates that show the chemical makeup, mechanical properties, and manufacturing methods. These certifications make sure that foreign standards are met. They also help fabricators use the right welding and heat treatment methods.

Detailed Breakdown of the Steel Truss Bridge Fabrication Process

The fabrication method makes finished structural parts from raw materials by following a set of carefully controlled steps. Each step needs special tools, expert tradespeople, and strict quality checks to make sure that the dimensions and structure are correct.

Design and Engineering Phase

Computer-aided design software lets engineers make accurate drawings for fabrication, do finite element analysis, and make sure that members are the right size. Building Information Modeling (BIM) technology helps design teams, builders, and building crews work together more easily, which makes projects more efficient and lowers the chances of mistakes.

Structural research shows that all parts can handle the design loads with the right safety factors. To make sure the steel truss bridge will work well for its entire working life, the effects of wind, earthquakes, and temperature are carefully planned for.

Material Procurement and Preparation

Certified steel suppliers have to go through tough tests to show that they can make good products and handle their quality well. Material traceability paperwork follows each heat of steel from the mill to the final installation. This makes sure that people are responsible for their work and can quickly respond to any quality issues.

Plasma and flame cutting both give raw plates and structural forms exact dimensions. Computer-controlled cutting tools can get tolerances within ±0.2mm, which means that when the parts are put together, they will fit without any issues.

Welding and Fabrication Operations

Certified welders use methods that are known to work when they join solid parts. Before welding, between passes, and after welding, the temperatures and procedures must be followed to make sure the weld stays strong when it is used. Automated welding systems make sure that the welds are always deep and that the shape of the metal is not changed in important links.

Before parts are sent out, full-node checking with magnetic particle testing (MT) and ultrasonic testing (UT) technologies finds any issues. These non-destructive tests find flaws on and below the surface that could hurt the structure's performance.

Assembly and Erection of Steel Truss Bridges On-Site

On-site assembly transforms individual fabricated components into complete bridge structures. In this phase, several trades must work together very carefully. Specialized lifting tools and strict safety rules are needed to protect workers and the public.

Site Preparation and Logistics

As part of foundation preparation, anchor bolts must be set to exact heights and angles. Survey control sets up reference points that show how far away truss pieces can be from the ideal position and still be acceptable. Assembly sequences and material arrival schedules work together so that storage space and handling time are not wasted.

Component weights, lift angles, and site limitations all affect crane choice. Main truss sections are usually handled by mobile cranes with more than 100 tons of capacity. Secondary members and decking elements are then put in place by smaller machines.

Sequential Assembly Procedures

Modular design makes it easy to put together quickly pre-fabricated frame parts. How to connect it together uses either high-strength bolts or field welding, which depends on how it's designed and the conditions at the spot. During building, temporary supports keep everything stable, and they are only taken away once the final links are fully set.

Checking the dimensions at each stage of assembly stops errors from building up, which could change how the parts fit together at the end. Optical measurement tools keep an eye on deflections and make sure that geometric needs are met.

Emergency Bridge Applications

Emergency steel truss bridge systems that can be taken apart show how flexible steel truss technology can be used in many different ways. These specialized buildings make it possible to cross a 200-meter river in 48 hours. This creates an important way to get around when there are natural disasters or problems with infrastructure. Standardized link information and pre-designed parts make it easy for trained teams with portable tools to set things up quickly.

Maintenance and Durability Optimization Post-Assembly

Long-term performance relies on a corrosion protection, fatigue monitoring, and component replacement as needed. Proactive methods keep costs low and make sure that safe operation continues even when traffic demands rise.

Corrosion Protection Systems

In tough conditions, advanced anti-corrosion treatments keep surfaces safe for decades. Thermal spray zinc coatings (160μm thick) stop steel from oxidizing by creating sacrificial shields. Epoxy mica middle coats fill in gaps on the surface, and polyurethane top coats protect against damage from UV rays and chemicals.

Regularly checking the coating's state and noting where maintenance is needed. Before a lot of damage happens, touch-up methods restore protection. This makes the system last longer overall.

Structural Health Monitoring

Today’s bridges have sensor networks that keep an eye on the amounts of strain, the way vibrations move, and the weather at all times. Data analysis finds problems before they affect the capacity of the service, which makes focused maintenance possible.

Critical features that are prone to cracking under repeated loading should be carefully monitored. Based on the design codes' stress levels and detail categories, the time between inspections can change.

Selecting the Right Partners for Fabrication and Assembly

Bridge projects only succeed when they are done in partnership with skilled makers who show that they know a lot about the field, can handle quality, and can be counted on to deliver on time. The standards for evaluation should include both technical skills and business practices that make it possible for people to work together in the long run.

Quality Management Certifications

ISO 9001, ISO 14001, and OHSAS 45001 certifications show that you have a solid system in place to control the quality of your work, protect the environment, and keep your workers safe. The EN 1090 approval makes sure that the work done on structural steel complies with European technical standards that are being used around the world.

Regular checks by certification bodies make sure that ongoing compliance and attempts to improve are done. These tests from third parties show that the suppliers are capable and dedicated to doing great work.

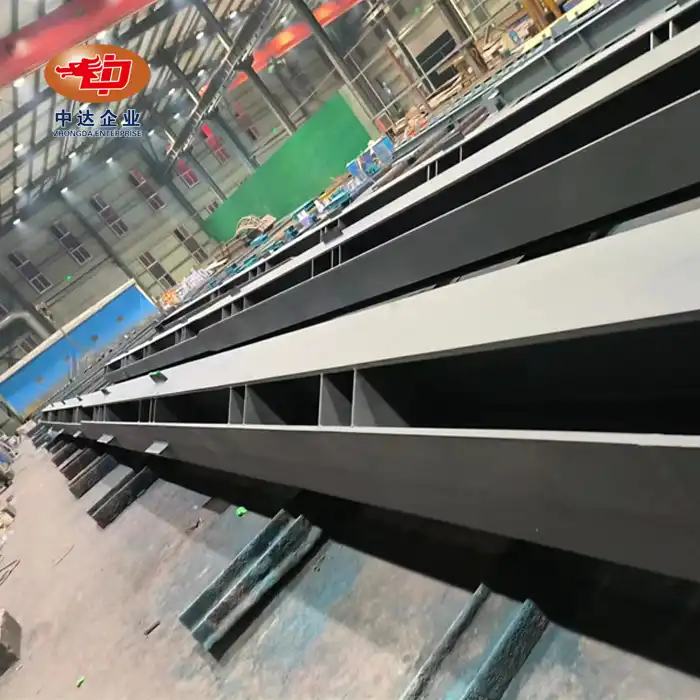

Production Capacity and Capabilities

Today's factories have special tools for moving and working with heavy parts. When it comes to moving big groups of parts around the factory floor, it works best to use cranes that can lift at least 50 tons. The ability to make more than 60,000 tons a year means that there are enough resources to work on big building projects.

With their 120,000 m² facility and operations that cover everything from planning to construction, Zhongda Steel Structure Engineering is a great example of a company that leads the industry. Their proven track record includes big projects for China's biggest infrastructure companies, like the 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge and several projects that made highways bigger.

Zhongda Steel Structure Engineering: Your Premier Heavy-Duty Steel Truss Bridge Manufacturer

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a top bridge builder and one of the best heavy-duty steel truss bridge makers. The company was started in 2004 and is based in the Shenyang Economic-Technological Development Zone. It has become a world-certified leader in precision steel products.

Advanced Manufacturing Capabilities

Our new facility has 120,000 m² of modern production room with the latest technology. The workshop with a 50-ton crane capacity makes it easy to work with heavy-duty materials, and BIM-based prefabrication methods make sure that parts are made exactly right. The ultra-thick plate cutting skills keep errors at ±0.2mm, which means that when you put the parts together, you don't have to worry about them not fitting.

The business can make 60,000 tons of product every year, which helps big building projects around the world. Vertically integrated capabilities from R&D to final building make sure that projects run smoothly and get great results at every stage.

Product Excellence and Innovation

Zhongda's heavy-duty steel truss bridges can be made with span lengths anywhere from 30 to 150 meters and can hold up to 100 tons of weight. Modular Warren and Pratt truss configurations make it easy to put things together and install them quickly, which cuts down on the time needed to complete a job.

The company's Weathering Steel Anti-Corrosion Technology, which works at temperatures as low as -60°C, gives great safety in tough settings. This high-tech system uses thermal spray zinc (160μm), epoxy mica, and polyurethane in such a way that the system lasts a long time and doesn't need to be taken care of very often.

Conclusion

Making and putting together steel truss bridges are complex engineering tasks that require technical knowledge, quality control, and a lot of attention to detail. Knowing these important steps helps you make smart choices during all stages of a project, from the first planning to the final commissioning. Using high-tech materials, manufacturing methods, and quality control systems in construction makes sure that the infrastructure will last for decades. Successful projects depend on relationships with qualified fabricators who show their skills, have a lot of certifications, and are dedicated to excellence. As the needs for infrastructure keep growing around the world, steel truss bridges will stay important for getting people and goods around, for factories, and for emergency response systems.

FAQs

How long in advance do you normally have to order a steel truss bridge so that it can be made in time?

The amount of time that fabrication leads depends on how complicated the project is and how far it needs to go. For standard plans, it usually takes between 12 and 20 weeks. If you need custom setups, you might need to spend more time engineering them, but our modular method can cut down on project length by 20–30% compared to standard ways of working. Early involvement with our tech team helps us use resources wisely and plan our time correctly.

How do you make sure the quality of the manufacturing process?

Magnetic Particle Testing (MT) and Ultrasonic Testing (UT) are two of the many quality control steps we take that check full nodes. Our ISO 9001-certified quality control system makes sure that the whole production process follows global guidelines. Before shipping, each part's dimensions are checked and its material source is recorded.

Can you make your bridges fit the needs of certain projects?

For sure. Our technical team is an expert at creating custom solutions using ASTM A709 Gr.50 steel with Z35 Z-direction properties. We can handle different environmental conditions, span lengths, and load needs. Using BIM in our planning process makes it possible to build complicated shapes exactly right. It also makes sure that the structure stays strong and the project doesn't go over budget.

Partner with Zhongda for Your Steel Truss Bridge Projects

With twenty years of experience in the field, Zhongda Steel Structure Engineering provides top-quality heavy-duty steel truss bridges. We can help with every step of a project, from the first planning to the last installation. We guarantee success by delivering on time and with great professional quality. We understand the tough needs of today's infrastructure projects because we have worked with big clients like China Railway, CSCEC, and BMW. Our steel truss bridge company can build an emergency bridge up to 200 meters in just 48 hours. If you want to talk about your exact needs and how our new ways of doing things can help your project, email us at Ava@zd-steels.com.

References

American Institute of Steel Construction. (2017). Steel Construction Manual, 15th Edition. Chicago: AISC Press.

Barsom, J.M. & Rolfe, S.T. (2018). Fracture and Fatigue Control in Structures: Applications of Fracture Mechanics, 4th Edition. Philadelphia: ASTM International.

Connor, R.J., Dexter, R., & Mahmoud, H. (2019). Inspection and Management of Bridges with Fracture-Critical Details. Washington, D.C.: Transportation Research Board.

Fisher, J.W., Kulak, G.L., & Smith, I.F.C. (2020). A Fatigue Primer for Structural Engineers, 2nd Edition. Bethlehem: Advanced Technology for Large Structural Systems.

Mertz, D.R. & Gillespie, J.W. (2021). Steel Bridge Design Handbook: Fabrication. Washington, D.C.: Federal Highway Administration.

Troitsky, M.S. (2018). Steel Truss Bridges: Theory, Behavior, and Design. New York: Engineering Press.

_副本_1760170327027.jpg)