Advanced structural engineering is very different from traditional building, and steel box girders are a good example of this. For heavy-duty uses, welded box girders are the best choice because they are made of continuous steel pieces that are joined together using complex welding methods. Modular box girders use premade pieces that are put together on-site, which makes shipping easier and speeds up the building process. Today, both types are used for different things in building infrastructure, and the choice depends on the needs of the project, the surroundings, and the logistics involved. Procurement pros can make choices that improve performance, cost-effectiveness, and project delivery plans by understanding these structure differences.

Understanding Steel Box Girders: Basics and Types

Steel box girders are hollow structural parts that are very strong for their weight. They are used to build bridges and other structures. The cross-sections of these designed parts are rectangular or trapezoidal, which makes them better at resisting twisting forces than standard I-beam options. Because they are hollow, they spread weight evenly and use as little material as possible, which makes them perfect for long-span uses where structural economy is very important.

Structural Design Principles

Modern bridge girders use advanced engineering techniques to keep the structure strong while increasing the load capacity. With the hollow box design, a closed piece is made that doesn't shift and is more stable when loads are applied dynamically. This way of designing works especially well when the span needs to be more than 100 meters, because regular beam structures would need too thick of a material.

Material Specifications and Performance

High-strength steel types like Q345D and Q420D are used in modern box girder building. These grades have yield strengths of more than 345 MPa and 420 MPa, respectively. Engineers can use these materials to cut down on weight while still meeting standards for structure performance. The choice between bonded and modular designs is usually based on how to best use materials and the makers' ability to make things.

Detailed Comparison of Welded and Modular Steel Box Girders

There is a big difference between bonded and modular methods for steel box girder in how they are put together and how the structures are built. Welded girders are made in a continuous process that makes buildings that are one piece, while modular systems use divided construction methods that focus on making assembly easier and shipping easier.

Fabrication Methods and Manufacturing Advantages

To make a welded box girder, constant welding methods are used to make structure parts that are smooth. With this method, producers can use automatic welding systems to get exact control over dimensions and better joint quality. Using continuous manufacturing lets you make beams with different cross-sections and heights, from 1.25 meters to 8 meters, so you can meet the needs of a wide range of projects.

Modular beam systems use pre-made pieces that are usually between 12 and 30 meters long. Before being sent to building sites to be put together for good, these pieces go through factory-controlled manufacturing processes. Compared to traditional methods, this method cuts down on building time on-site by about 50% while keeping quality standards through controlled factory settings.

Structural Performance Characteristics

It is better for girders that are welded to have consistency qualities that make load distribution better and stress concentrations lessen. Because the structure is one piece, there are no weak spots like there are with field links. This makes it more resistant to failure under repeated loading conditions. In bridge uses with a lot of traffic, where long-term reliability is important, this feature is especially useful.

Modular systems give you more options for how the spans are set up and how they are built. The divided method lets engineers make sure that each part works best in a certain set of pressure conditions while keeping the total performance of the structure high. Additionally, flexible designs make it easier to maintain and change parts throughout the structure's lifetime.

Application Scenarios and Decision-Making Criteria

The choice between bonded and modular designs is based on the needs of the project. The best choice for each application depends on the environment, the length of the span needed, the time it takes to build, and the cost of upkeep.

Long-Span Bridge Applications

Welded steel box girder works really well in long-span situations where keeping the structure the same is important for getting the best performance. These systems can make single spans up to 420 meters long while keeping the structure efficient by distributing materials in the best way possible. The continuous building method lets you make complicated geometric shapes that can fit bent lines and different grades.

Modular methods are very helpful for infrastructure projects that need to be built quickly. Prefabricated systems save time and are useful for projects like expanding highways, replacing railroad bridges, and rebuilding quickly after an accident. The factory-controlled setting makes sure that the standard is always the same, and it also cuts down on building delays caused by bad weather.

Environmental Considerations

Both bonded and modular systems have to choose the right materials and protect themselves from harsh environments. Modern anti-corrosion methods, like welding and special coatings, can extend the service life of metals by more than 30 years. The current frame design uses two types of safety methods to meet the tough needs of sea settings, manufacturing sites, and harsh weather.

Procurement Insights: How to Source the Right Steel Box Girders

For buying plans to work, they need to look at everything about the company, including their skills, quality standards, and the stability of their supply chain. To get the best project results, the decision method includes combining expert needs with business concerns.

Manufacturer Selection Criteria

The best companies that make steel structures have complete quality control systems that are certified by ISO 9001, EN 1090, and AWS. These qualifications make sure that the making process is always the same and that international standards are followed. When it comes to big projects, production ability is very important, and well-known producers can produce more than 60,000 tons per year.

Location affects shipping prices and arrival times, especially for flexible systems that need to be shipped in more than one package. Manufacturers that do business all over the world have established delivery networks and project experience working on projects in other countries, which can help with logistics. Being able to offer professional support and construction help in the local area makes the buying process much more valuable.

Customization and Technical Support

Today's buyers of steel box girder want more than just basic products; they also want to be able to fully customize them. Advanced makers offer design merging based on BIM, changeable cross-section optimization, and rust protection systems that are specially made for each climate. With these tools, buying teams can meet their performance goals while also cutting costs and speeding up the project.

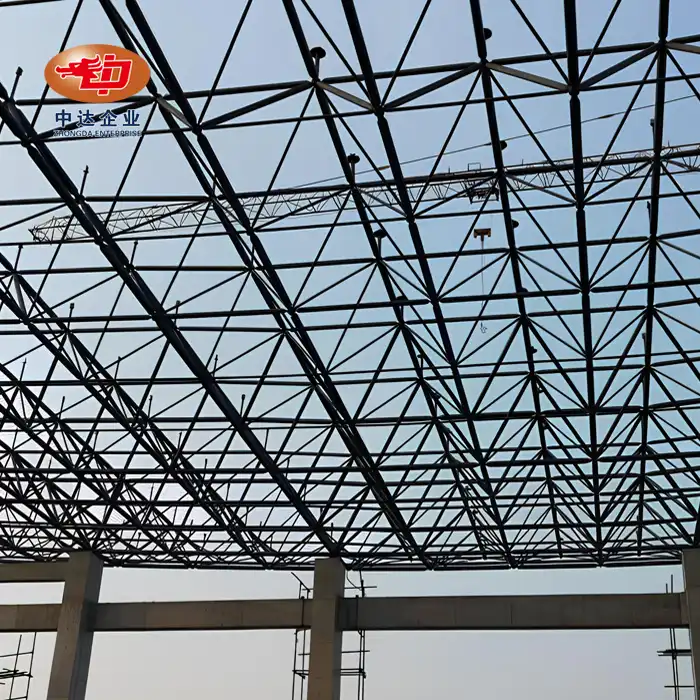

Company Introduction and Product & Service Information

Shenyang Zhongda Steel Structure Engineering Co., Ltd. has been making and selling high-tech steel box girders to building markets around the world since 2004. Our 120,000-square-meter factory in the Shenyang Economic-Technological Development Zone has cutting-edge CNC ultra-thick plate cutting systems and automatic welding lines that make sure our products are made precisely to within ±0.2mm limits.

Our wide range of products includes both bonded and flexible box girder systems that are designed to work in tough building situations. The fully welded box section design provides the best strength distribution for building a long-span bridge, and our modular systems allow for faster construction by prefabricating parts in the plant. Key production skills include cross-section designs that can be changed in size and shape, flexible steel web choices that can cut weight by 20%, and a maximum single span length of 420 meters.

Quality control is still the most important part of our manufacturing process, and we follow strict testing and checking rules at every stage of production. Our licenses include ISO 9001/14001/45001, Class I Steel Structure Professional Contracting Qualification, EN 1090, and AWS standards, which mean that the quality of our work is always the same and meets standards around the world. The yearly production capacity of 60,000 tons supports large-scale infrastructure projects and keeps delivery plans that cut project lead times by 20 to 30 percent.

Important project examples show that we can provide high-quality answers to a wide range of infrastructure problems. The 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge shows how good we are at building complicated, large-scale structures. Our work with global EPC firms shows how committed we are to building infrastructure around the world. Our 70% client return rate shows the long-term relationships we've built by always doing a great job and being technically proficient.

Conclusion

Whether to use welding or modular steel box girders relies on the needs of the project, such as the length of the span, the time it takes to build, the weather, and the need for long-term upkeep. Welded systems offer better structural consistency and performance improvement for complicated, long-span applications, while flexible methods make building faster and easier for projects that need to be finished quickly. To make sure the best project results, it's important to carefully look at the manufacturer's skills, quality certifications, and expert support services before making a purchase. Manufacturing technologies and material studies are always getting better, which means that both bonded and modular systems will work better and cost less in the future when building infrastructure.

FAQs

How are welded and flexible steel box girders structurally different from each other?

Welded box girders are made up of continuous steel pieces that are joined together using a variety of welding techniques. This creates a single, uniform frame that is better at spreading load. Modular systems use premade parts that are put together on-site, which makes shipping more flexible and speeds up the building process. The welding method gives the structure more continuity, while flexible designs make it easier to do upkeep and allow for faster assembly.

How are the upkeep needs for these two types of girders different?

Welded girders usually don't need to be maintained as often because they are made of one piece and have fewer connection spots. But when repair needs to be done, it can be harder to get to. Connection places in modular systems may need to be checked more often, but it's easy to change parts. Both types have improved anti-corrosion processes that make them last longer than 30 years.

Which type is more cost-effective for building big infrastructure projects?

Cost-effectiveness rests on things like the length of the span, how long it takes to build, and how easy it is to get to the spot. For complicated, long-span uses, welded girders often offer better long-term value because they need less upkeep. Most of the time, modular systems have lower starting costs and faster building plans. This means that total project costs are lower because construction takes less time and toll sites start making money sooner.

Partner with Zhongda for Your Next Infrastructure Project

We are the best company to get steel box girders from for your next building project because we have the most modern production tools and a track record of success. Our vertically integrated method includes everything from optimizing designs using BIM to helping with the final installation, making sure the project runs smoothly. Our -60°C weathering steel technology and 60,000-ton annual production capacity allow us to provide solutions that meet the strictest requirements while still meeting tight deadlines.

Our engineering team offers full technical support throughout the whole project lifetime, whether you need welded systems for building a long-span bridge or flexible solutions for quick deployment. Our list of global certifications and relationships with major infrastructure builders show that we are dedicated to quality and dependability. Email us at Ava@zd-steels.com for full specs and quotes that are made just for your job.

References

Chen, W.F. and Duan, L. (2014). "Bridge Engineering Handbook: Construction and Maintenance." CRC Press, Second Edition.

Troitsky, M.S. (2019). "Steel Box Girder Bridge Design: Principles and Applications." Engineering Publications International.

American Institute of Steel Construction. (2017). "Steel Construction Manual." AISC 360-16, Fifteenth Edition.

European Committee for Standardization. (2018). "Eurocode 3: Design of Steel Structures - Part 2: Steel Bridges." EN 1993-2.

Xanthakos, P.P. (2020). "Theory and Design of Bridges: Steel and Composite Construction Methods." John Wiley & Sons, Third Edition.

International Association for Bridge and Structural Engineering. (2019). "Guidelines for the Design of Steel Box Girder Bridges." IABSE Structural Engineering Documents.

_副本_1754115287719.jpg)

(1)_副本_1760321095013.jpg)

_副本_1758525665999.jpg)

_副本_1755847812558.jpg)