The price of a steel box girder project depends on many factors that are all linked and need to be carefully considered by buying professionals. The final project cost depends on the types of materials used, the complexity of the design, the production process, the logistics of shipping, and the fitting needs. When engineering teams know about these factors, they can make smart choices that meet performance needs and stay within budget. To get good steel box girder options, you need to plan ahead, choose the right provider, and think about the long-term value as well as the starting costs.

Key Factors Influencing the Cost of Steel Box Girder Projects

One of the main things that affects the cost of any structural steel job is the material specs. Choosing between different types of steel has a direct effect on both the cost of the material and how well it works. Knowing about these important factors helps project managers set costs correctly.

Material Grade and Quality Standards

When it comes to important parts, high-strength steel types like Q345D (≥345MPa) and Q420D work better than regular structural steel, but they cost more. These materials are better at holding weight and lasting longer, which is especially important for long-span uses. The higher cost of luxury materials usually means less upkeep and a longer working life, which makes them cost-effective over the span of the project.

Design Complexity and Customization Requirements

Because they make production more complicated, variable cross-section shapes have a big effect on manufacturing costs. For projects that need beam heights between 1.25m and 8m, you need special tools and skilled workers. Corrugated steel web technology, on the other hand, can help improved designs lose up to 20% of their weight. This could make up for higher manufacturing costs by saving money on materials and shipping.

Manufacturing Processes and Lead Times

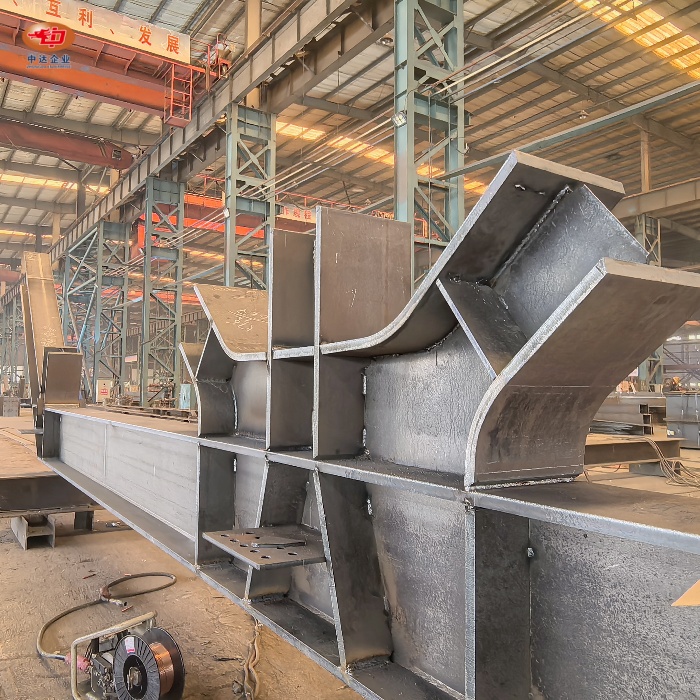

Advanced industrial methods, like CNC ultra-thick plate cutting with ±0.2mm accuracy and automatic welding systems, make sure that the quality is always the same, but they need a lot of money to buy the right tools and trained workers to run them. These methods help makers get better surface finishing and tighter standards, which cuts down on the time and effort needed for modifications in the field. The fully welded box building method gives the best spread of strength, but it needs special welding skills and quality control processes.

Comparative Analysis: Steel Box Girder vs Other Girders and Cost Implications

When buying workers look at different building choices for steel box girder, they need to think about both the short-term costs and the long-term benefits. Depending on the needs of the project, the surroundings, and the expected performance, each type of frame has its own benefits.

Performance Advantages Over Traditional I-Beams

I-beams are not as efficient as steel box girders when it comes to building structures, especially when the spans are long (up to 420 meters). The closed-section design makes the structure more rigid in the torso and less likely to buckle in the side, so it doesn't need as many extra supporting elements. While the original prices may be higher than those of I-beam options, the better structural performance often makes the investment worth it by lowering the total amount of steel that needs to be used.

Lifecycle Cost Considerations

Modern anti-corrosion methods, like welding or special covering systems that provide double protection, make things last longer and require less upkeep, up to 30 years or more. This advantage of stability is especially useful in tough settings where regular materials might need to be fixed or replaced more often. When considering different building options, these long-term rewards must be factored into the total cost of ownership estimate.

Procurement Considerations Impacting Project Cost

The choice of supplier has a big effect on project prices that go beyond the cost of materials. When looking at possible partners, it's important to think carefully about their manufacturing skills, quality certifications, and service offers, all of which affect the overall value of the project.

Manufacturing Capabilities and Certifications

Certified makers with ISO 9001, EN 1090, and AWS credentials show that they are dedicated to quality standards that lower the risk of a project. With the ability to produce 60,000 tons per year, advanced factories can handle big projects while keeping wait times low. Offering technical help and BIM-based design integration throughout the entire project lifecycle is a big plus that goes beyond just supplying products.

Prefabrication and Delivery Optimization

Factory prefabrication of steel box girder parts that are 12 to 30 meters long makes it possible to quickly put them together on-site, which can cut building time by up to 50%. This method cuts down on the need for welding in the field and delays caused by bad weather while maintaining uniform quality control. But moving big parts around needs special planning for handling, and it might raise the overall cost of the job based on how easy it is to get to the spot and the rules for transportation in the area.

Cost Optimization Strategies for Steel Box Girder Projects

To control costs effectively, you need to use strategic methods that look at how to make designs more efficient, how to make production more efficient, and how to build partnerships with suppliers. These methods help project teams get the most out of their resources while still meeting quality standards.

Design and Engineering Optimization

Using advanced modeling tools and collaborative design methods, it is possible to find ways to improve the performance of materials without affecting the structure itself. Working closely with experienced makers during the planning phase lets you add features that are easy to make, which lowers the cost and complexity of production. When people work together, they often come up with new ideas that improve performance and cut costs.

Strategic Supplier Relationships

When you form long-term relationships with qualified makers of steel box girder, you can get better technical help, lower prices, and faster timing. Suppliers who have worked on big projects before, like the 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge, can help you avoid having to make expensive changes to the plan or delays in building. Because of better planning and organization, these ties often cut project lead times by 20 to 30 percent.

Zhongda Steel: Your Trusted Steel Box Girder Manufacturer

The steel box girder products made by Shenyang Zhongda Steel Structure Engineering Co., Ltd. are of the highest quality and meet international engineering standards. We have been in business since 2004 and are based in the Shenyang Economic-Technological Development Zone. With ISO 9001/14001/OHSAS 45001 and EN 1090 standards, we are the world's leading provider of precision steel products.

Our 120,000 m² modern factory has cutting-edge tools for making things, like CNC ultra-thick plate cutting with ±0.2mm accuracy and automatic welding systems. We serve global B2B clients in the building, energy, and industry sectors with a production capacity of 60,000 tons per year. Our experience includes building bridges across the Arctic in Russia and supporting mining equipment in Australia. This shows that we can handle a wide range of difficult tasks.

Our steel box girder options have many benefits, such as a fully welded box structure for even strength distribution, beam heights that can be changed from 1.25m to 8m, and improved anti-corrosion processes that guarantee over 30 years of service life. Our method to prefabrication, which is based on BIM, cuts building plans by 50% while keeping high quality standards. We provide full OEM and ODM services, with flexible cross-section designs that can cut weight by up to 20% thanks to new folded steel web technology.

Conclusion

When buying workers know what factors affect the cost of steel box girder projects, they can make decisions that are best for both performance and budget. Specifications for materials, the difficulty of the design, the methods used to make the product, and the supplier's skills all affect the total cost of the project in different but linked ways. Instead of just looking at the original prices, it's important to look at the project's total lifetime value. When you think about long-term upkeep needs, strategic partnerships with suppliers, and design optimization are some of the reasons why it's often worth spending more on high-quality materials and manufacturing methods. Engineering teams can get the best results on projects that meet both professional needs and financial goals by carefully weighing these factors.

FAQs

How long does it usually take to make a handmade steel box girder?

Depending on the difficulty of the design, the amount of production, and the factory's ability to make the product, lead times are usually between 4 and 12 weeks. Projects that need special materials or complicated shapes may go beyond this range. Planning ahead and involving suppliers early on help keep delays to a minimum and guarantee on-time project performance.

How does the lifetime cost of a steel box girder affect the total cost of ownership?

Superior resilience greatly lowers the need for upkeep and increases the service life, which results in lower lifetime costs even if the initial investment is higher. With proper anti-corrosion treatments, high-quality materials can last for over 30 years with little upkeep, saving you money in the long run.

Can steel box girders meet the needs of complicated buildings?

Modern production techniques allow for a lot of customizing, such as different cross-sections and unique shapes. Using advanced design tools and integrating BIM lets architects and engineers make the most of both the function and appearance of a building while keeping costs low.

Partner with Zhongda for Your Next Steel Box Girder Project

Are you ready to improve your infrastructure project with strong, dependable building solutions? Zhongda's special steel box girder production skills, along with our advanced construction skills and global project knowledge, make sure that your investment is well spent. Our team offers full support from the first planning meeting to the final installation. They do this by drawing on decades of experience working on large building projects around the world.

As one of the biggest companies that sells steel box girders, we can offer you affordable options that are made to fit the needs of your project. Our engineering team works with you to find the best options that meet your needs in terms of performance, cost, and delivery, whether you need long-span bridge parts, industrial building frames, or unique structure elements. Email us at Ava@zd-steels.com to set up a personal meeting and get a full quote.

_1756188318306.png)

_副本_1758525876027.jpg)

_1755137539095.png)