China is the world leader in making structural steel because it has the largest production capacity, the most advanced manufacturing technologies, and the most cost-effective options for a wide range of industry needs. With more than 1 billion tons of steel produced every year, China is the world's biggest producer. As a result, Chinese manufacturers have developed advanced skills in making high-quality steel beams, columns, and custom-fabricated parts that meet international standards while keeping prices low enough to benefit procurement teams around the world.

Understanding Structural Steel and Its Manufacturing Landscape in China

China's steel industry environment is the world's largest and most highly advanced production network. The way the country makes steel uses a combination of modern metallurgy, precision manufacturing, and the acquisition of raw materials to ensure uniform quality across all steel types and standards.

Types and Applications of Chinese Steel Products

Chinese companies are experts at making a wide range of steel goods that are specifically designed to meet the needs of different industries. Hot-rolled steel pieces are the building blocks of many projects, while cold-formed steel parts are used in specific situations where exact measurements and better surface finishes are needed. For building projects in harsh locations, weathering steel types offer better rust protection, and high-strength steel grades are used for heavy-duty industry tasks.

The first step in making something is carefully choosing the raw materials. Next, steel is made in an electric arc furnace or a basic oxygen furnace. Continuous casting technology is used in Chinese factories to make sure that all of the products have the same chemical makeup and mechanical qualities.

Quality Standards and Certifications

International standards like ASTM, EN, JIS, and GB national standards are followed by Chinese steel producers for structural steel as part of their strict quality systems. Leading businesses keep their ISO 9001 quality management systems, ISO 14001 environmental management systems, and OHSAS 18001 health and safety at work guidelines up to date. These approvals make sure that goods meet the strict standards set by global markets for chemical makeup, mechanical features, measurement limits, and surface quality.

Core Competitive Advantages of China in Structural Steel Manufacturing

China's steel industry has a lot of basic benefits that make it a great deal for foreign buyers who want solid, low-cost steel options.

Manufacturing Scale and Cost Efficiency

China makes so much steel that it creates economies of scale that give buying teams direct cost benefits. China's yearly steel production makes up about half of the world's total. This helps producers get the best deals on raw materials, energy use, and production schedules. Because they are bigger, Chinese providers can offer competitive prices while still making enough money to keep investing in technology and quality improvements.

Over the past ten years, Chinese steel factories have become much more productive thanks to robotics and improved process control systems that lower the cost of labor per unit while also making the quality of the products more consistent. Modern Chinese steel plants use about as little energy as the world's best ones, which helps the country's total cost competitiveness.

Technological Innovation and Manufacturing Capabilities

Chinese steel companies have put a lot of money into new production methods that improve the quality of their products and make them easier to make. Some of the advanced features that are used in top centers are:

- Plasma and laser technology in automated cutting systems allow for precise tolerances of ±0.2mm for complicated shapes and unique requirements.

- Computer-controlled rolling mills that make sure the same level of surface quality and precision in measurements over long production runs

- Sophisticated heat treatment processes that optimize mechanical properties for specific application requirements

- Systems that keep an eye on chemical makeup, dynamic traits, and physical characteristics in real time during production

Because of these technological advances, Chinese makers can handle complicated custom manufacturing projects for structural steel while still benefiting from the cost savings of mass production. Integrating Building Information Modeling (BIM) systems makes it possible for design requirements and manufacturing processes to work together more smoothly. This cuts down on wait times and waste.

Supply Chain Infrastructure and Logistics

Through an integrated network of ports, trains, and interior transportation systems, China's extensive shipping infrastructure makes it easy to get steel to markets around the world. Areas that make a lot of steel have direct access to deep-water ports that can handle big bulk ships. This makes shipping goods across international borders cheaper and faster.

The country has a very large train network that makes it cheap to move raw materials to factories and produced goods to ports for sale. Because China has better facilities, they can offer competitive delivered prices to markets around the world while still keeping delivery dates.

How China's Structural Steel Meets Global B2B Procurement Needs?

Chinese steelmakers have come up with business models that are perfect for meeting the complicated needs of foreign buying teams. These models offer adaptable options that balance cost, quality, and delivery performance.

Quality Assurance and Compliance

The best steel manufacturers in China use complete quality control systems that go above and beyond what the industry requires for consistent and reliable products. These systems include checking arriving materials, keeping an eye on the work in progress, and testing the finished product with cutting-edge lab gear. There are many third-party inspection services that can independently check that a product meets worldwide standards and meets the requirements of its specs.

Case studies show how complicated projects like building infrastructure in Southeast Asia, mining facilities in Australia, and industrial sites in Africa were completed successfully. These projects show that Chinese makers can meet strict technical requirements while still following global rules for safety and the environment.

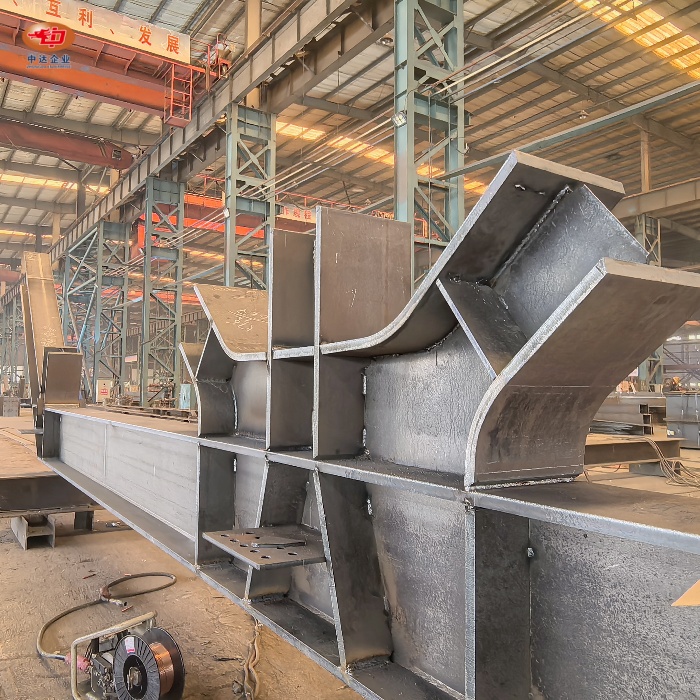

Flexible Manufacturing and Customization

Chinese steel factories are great at meeting the needs for structural steel of a wide range of buyers, including those with different budgets and order sizes. Manufacturers keep up with efficient production schedules that makes the best use of wait times and cost structures, whether they are making a lot of standard goods or a few unique ones.

Custom manufacturing includes complicated welding systems, unique surface treatments, and precise milling tasks that make steel production more valuable than just making steel. With this all-in-one service, buying teams can streamline their relationships with suppliers and get full answers for complicated projects.

Navigating Supplier Selection: How to Choose the Right Structural Steel Supplier in China

To buy steel from Chinese sources successfully, you need to carefully consider a lot of factors that can affect the success of the relationship and the project itself.

Evaluation Criteria and Due Diligence

A good way to evaluate a provider is to check their key manufacturing skills, quality licenses, and financial security. Some of the most important things that are used to judge someone are their production ability, the level of professional knowledge they have, and their track record with similar tasks. Financial health signs, like credit scores, bank relationships, and insurance coverage, show how stable a provider is and how well they can handle risks.

When you do a technical skills review, you should look at things like lab testing facilities, quality control processes, and engineering support tools. Suppliers with in-house design teams and technical experts can add more value by letting you work together to solve problems and find the best solutions.

Risk Management and Quality Verification

Strong proof methods, such as plant checks, sample testing, and ongoing quality tracking throughout the supply relationship, should be used by procurement teams. Set rules for tracking materials, what paperwork is needed, and how to talk to each other help make sure that work is always done correctly and that regulations are followed.

Key risk factors for structural steel should be included in contract arrangements, such as delivery dates, quality standards, payment terms, and ways to settle disagreements. Clear review and acceptance standards protect the buyer's interests and make it clear to providers what kind of work is expected of them.

Zhongda Steel: Your Trusted Partner in Advanced Steel Solutions

Zhongda Steel is a great example of the advanced skills and high quality standards that make China's top steel producers stand out. Zhongda was established in 2004 and has its main office in the Shenyang Economic-Technological Development Zone. It has become a globally recognized leader in precision steel solutions, with ISO 9001/14001/OHSAS 45001 and EN 1090 certifications proving our dedication to quality, safety, and environmental responsibility.

Manufacturing Excellence and Technical Capabilities

Our current 120,000-square-meter building can handle 60,000 tons of material every year and specializes in BIM-driven prefabrication, which speeds up project planning and cuts down on construction times. The -60°C Weathering Steel Anti-corrosion Technology that Zhongda has created works in even the harshest environments. We can also cut ultra-thick plates with precise limits of ±0.2mm, which is perfect for complex industrial projects.

Because of their advanced production skills, well-known companies like China Railway, CSCEC, BMW, and many others from around the world in different industries believe them. Our list of great projects includes building an Arctic bridge in Russia, providing Australia with specialized mining tools, and creating industry hubs all over Vietnam. This shows that we can provide technical excellence that has an effect all over the world.

Global Reach and Customer Success

Because Zhongda is dedicated to new ideas, quick work, and constant quality, we are often chosen as a partner for difficult projects that need high performance and dependability. Our experienced engineering team works closely with clients to create the best solutions that meet their unique technology needs while still being cost-effective and on time.

Conclusion

China has big benefits when it comes to making structural steel, which opens up great possibilities for global buying teams looking for solid, low-cost options for a wide range of industrial uses. Chinese providers are great for complicated projects around the world because they can make a lot of things, use cutting-edge technology, have thorough quality systems, and have good transport infrastructure. To make the most of these benefits, you need to carefully choose your suppliers, have strong quality control measures in place, and make sure that everyone involved in the buying process knows what you need and what you expect.

FAQs

China is known for making what kinds of steel products?

China makes a wide range of products, such as hot-rolled sections, cold-formed parts, weathered steel, high-strength grades, and custom-built kits that meet foreign standards like ASTM, EN, JIS, and GB.

How long does it usually take to get steel from Chinese suppliers?

Lead times usually run from two to six weeks, but they rely on how complicated the product is, how many orders there are, and any special needs, such as making the product or setting up foreign shipping.

How can people who buy steel from China make sure it is of good quality?

Before making big orders, you should check the quality by asking for up-to-date certifications (ISO, ASTM, GB/T), auditing the plant, getting inspection reports from a third party, and looking over material test certificates.

Partner with Zhongda for Superior Steel Solutions

Zhongda Steel has the advanced production skills and track record that global sourcing teams need to make sure that projects are completed successfully. Our complete method includes the latest technology, strict quality standards, and a range of customizable choices that can be used to meet the needs of a wide range of industries. Zhongda has a long history of working with foreign customers and is dedicated to building success. They can provide the dependability and knowledge you need for your most difficult projects. Get in touch with our skilled staff to talk about your unique needs and find out how our skills as a structural steel maker can help your next project. You can email us at Ava@zd-steels.com for full advice and cheap prices.

References

World Steel Association. (2023). "Global Steel Production Trends and Market Analysis." Steel Statistical Yearbook.

Liu, Jianhua and Wang, Ming. (2022). "Technological Advancement in Chinese Steel Manufacturing: A Comprehensive Review." Journal of Iron and Steel Research International, Vol. 29, Issue 8.

China Iron and Steel Association. (2023). "Quality Standards and Certification Practices in Chinese Steel Industry." CISA Annual Report.

Zhang, Weiming et al. (2022). "Supply Chain Optimization in Chinese Steel Manufacturing: Infrastructure and Logistics Analysis." Materials Science and Engineering Conference Proceedings.

International Trade Administration. (2023). "China Steel Industry: Production Capacity and Export Market Analysis." US Department of Commerce Steel Industry Report.

Thompson, Robert and Chen, Li. (2022). "Quality Management Systems in Chinese Steel Manufacturing: International Standards Compliance." Quality Engineering International, Vol. 15, Issue 3.