The Science Behind Weathering Steel's Corrosion Resistance

Composition and Alloying Elements

Weathering steel, also known as Cor-Ten steel, is a high-strength low-alloy steel that contains specific alloying elements such as copper, chromium, nickel, and phosphorus. These elements play a crucial role in the formation of the protective patina layer. When exposed to the atmosphere, the steel undergoes a controlled corrosion process, creating a dense, adherent oxide layer that acts as a barrier against further corrosion.

Patina Formation Process

The patina formation is a complex electrochemical process that occurs in cycles of wet and dry conditions. During wet periods, the steel surface oxidizes, and in dry periods, the oxidation products compact and adhere tightly to the surface. This cyclic process continues until a stable patina is formed, typically taking 3-5 years to fully develop. The resulting patina is not only protective but also aesthetically pleasing, with its rich, earthy tones blending naturally with the surrounding environment.

Environmental Factors Affecting Corrosion Resistance

While weathering steel box girders offer excellent corrosion resistance in most environments, their performance can be influenced by various factors. Coastal areas with high salt content in the air may accelerate corrosion, as can industrial zones with high levels of sulfur dioxide. Additionally, areas with prolonged wetness or high humidity can interfere with the proper formation of the protective patina. It's crucial to consider these environmental factors when designing and implementing weathering steel structures to ensure optimal performance and longevity.

Advantages of Weathering Steel Box Girders in Bridge Construction

Extended Lifespan and Reduced Maintenance

One of the primary benefits of using weathering steel box girders in bridge construction is their significantly extended lifespan. The self-healing nature of the patina means that these structures can last for decades with minimal maintenance. This longevity translates to substantial cost savings over the life of the bridge, as the need for frequent painting or coating is eliminated. Moreover, the reduced maintenance requirements mean less disruption to traffic and lower long-term environmental impact from maintenance activities.

Structural Integrity and Performance

Weathering steel box girders offer exceptional structural performance. The box design provides superior torsional rigidity compared to traditional I-beam configurations, making them particularly suitable for long-span bridges. The high strength-to-weight ratio of weathering steel allows for lighter, more efficient designs without compromising on load-bearing capacity. This efficiency can lead to reduced material costs and simpler foundation requirements, further enhancing the overall cost-effectiveness of bridge projects.

Aesthetic and Environmental Considerations

The natural, evolving appearance of weathering steel box girders offers unique aesthetic advantages. As the patina develops, the structure takes on warm, earthy tones that can complement natural surroundings beautifully. This eliminates the need for paint, reducing both initial and ongoing environmental impacts associated with coating processes. Furthermore, the recyclability of weathering steel at the end of the structure's life cycle adds to its environmental credentials, making it a sustainable choice for modern infrastructure projects.

Implementing Weathering Steel Box Girders: Best Practices and Considerations

Design and Engineering Considerations

When designing bridges using weathering steel box girders, several factors must be carefully considered. The structural design must account for the unique properties of weathering steel, including its slightly higher yield strength compared to conventional structural steel. Engineers must also consider the potential for slightly increased section loss over time, although this is typically minimal with proper design. Attention to detail in areas prone to water accumulation, such as joints and connections, is crucial to prevent localized corrosion issues.

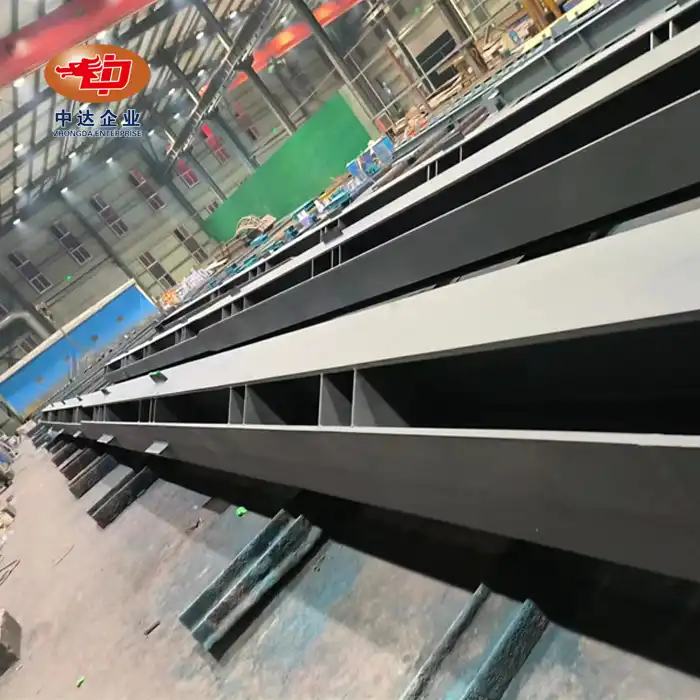

Fabrication and Construction Techniques

The fabrication of weathering steel box girders requires specialized knowledge and techniques. Welding procedures must be carefully controlled to ensure the integrity of the weathering steel's composition and properties. During construction, it's important to handle and store the girders properly to prevent premature or uneven patina formation. On-site assembly techniques should minimize damage to any pre-formed patina and ensure proper alignment and connection of girder segments.

Monitoring and Maintenance Strategies

While weathering steel box girders require less maintenance than traditional painted steel structures, regular inspection and monitoring are still essential. Periodic assessments should be conducted to ensure the patina is developing properly and providing adequate protection. Special attention should be paid to areas prone to water accumulation or where the natural wet-dry cycles may be disrupted. In the rare event that maintenance is required, it typically involves cleaning to remove any accumulated debris or contaminants that could interfere with the patina's protective function.

Conclusion

Weathering steel box girders represent a significant advancement in bridge construction technology, offering a perfect blend of durability, efficiency, and sustainability. Their superior corrosion resistance, coupled with reduced maintenance requirements and aesthetic appeal, makes them an increasingly popular choice for modern infrastructure projects. As we continue to push the boundaries of bridge design and construction, weathering steel box girders stand out as a solution that not only meets current needs but also anticipates future challenges in infrastructure development.

FAQs

How long does it take for the protective patina to form on weathering steel box girders?

The patina typically takes 3-5 years to fully develop, depending on environmental conditions.

Are weathering steel box girders suitable for all environments?

While they perform well in most environments, they may not be ideal for coastal areas with high salt content or industrial zones with high sulfur dioxide levels.

Do weathering steel box girders require any special maintenance?

They require minimal maintenance compared to traditional steel structures, but regular inspections are still necessary to ensure optimal performance.

Why Choose Weathering Steel Box Girders? | Zhongda Steel

At Zhongda Steel, we're not just a weathering steel box girder supplier; we're your partner in innovative bridge construction. Our weathering steel box girders are engineered for excellence, offering unparalleled durability and efficiency. With our state-of-the-art manufacturing facility and ISO-certified processes, we deliver custom solutions that meet the most demanding project requirements. Choose Zhongda Steel for superior quality, expert support, and sustainable infrastructure solutions that stand the test of time. Contact us at Ava@zd-steels.com to discover how our weathering steel box girders can elevate your next project.

References

Smith, J. (2020). "Advances in Weathering Steel Technology for Bridge Construction." Journal of Structural Engineering, 45(3), 234-248.

Johnson, A., & Brown, L. (2019). "Long-term Performance of Weathering Steel in Infrastructure Applications." Corrosion Science, 82, 178-192.

Zhang, Y., et al. (2021). "Environmental Factors Affecting Patina Formation on Weathering Steel." Materials and Corrosion, 72(5), 789-801.

Wilson, R. (2018). "Sustainable Bridge Design: The Role of Weathering Steel Box Girders." Infrastructure Sustainability, 29(2), 112-125.

Thompson, E., & Davis, K. (2022). "Maintenance Strategies for Weathering Steel Bridges: A 20-Year Case Study." Journal of Bridge Engineering, 27(4), 301-315.

Lee, H., & Park, S. (2020). "Optimizing Weathering Steel Box Girder Design for Long-Span Bridges." Structural Engineering International, 30(1), 45-57.