Material Selection and Preparation

Choosing the Right Steel Grade

The foundation of a robust weathering steel box girder lies in selecting the appropriate steel grade. At Zhongda Steel, we primarily use Q345D steel for the main structure, which offers a minimum yield strength of 345 MPa. For critical joint areas that require extra strength, we opt for Q420D steel. These high-performance materials ensure our girders can withstand extreme loads and harsh environmental conditions.

Our commitment to quality begins at the sourcing stage. We work closely with reputable steel mills to procure materials that meet our stringent specifications. Each batch of steel undergoes thorough chemical and mechanical testing to verify its properties before entering our production line.

Plate Cutting and Shaping

Once the raw materials are approved, we move on to the cutting and shaping phase. Our state-of-the-art CNC cutting machines offer precision cuts with tolerances as tight as ±0.2mm, even on ultra-thick plates. This level of accuracy is crucial for ensuring proper fit during assembly and optimal structural performance.

For complex geometries, we employ advanced plasma and laser cutting technologies. These methods allow us to create intricate shapes and openings without compromising the steel's integrity. Our -60°C Weathering Steel Anti-corrosion Technology ensures that even cut edges maintain their corrosion-resistant properties.

Surface Preparation

Proper surface preparation is essential for the formation of the protective patina on weathering steel. We use a combination of shot blasting and grinding to achieve the desired surface profile. This process removes any mill scale or contaminants and creates a uniform surface that promotes even patina development.

For areas that require welding, we take extra care to clean and prepare the surfaces to ensure strong, defect-free joints. Our surface preparation techniques contribute to the long-term durability of our weathering steel box girders, which can exceed 33 years of service life with minimal maintenance.

Welding and Assembly Techniques

Advanced Welding Processes

Welding is a critical aspect of fabricating weathering steel box girders. At Zhongda Steel, we employ a variety of advanced welding techniques to ensure the highest quality joints. Our primary methods include submerged arc welding (SAW) for long, straight seams and flux-cored arc welding (FCAW) for more versatile applications.

We've invested in automated welding systems that provide consistent, high-quality welds while improving efficiency. These systems are particularly beneficial for the long, continuous welds required in box girder fabrication. For complex joints or areas with limited access, our skilled welders perform manual welding using specialized techniques to maintain weld integrity.

Quality Control in Welding

Our welding processes are governed by rigorous quality control measures. We conduct both destructive and non-destructive testing on weld samples to verify strength and integrity. Ultrasonic and magnetic particle inspections are routinely performed to detect any internal or surface defects.

All welding is carried out in accordance with international standards and our ISO 9001-certified quality management system. This ensures that every weld meets or exceeds the required specifications, contributing to the overall structural integrity of the weathering steel box girder.

Assembly and Fit-up

The assembly of weathering steel box girders requires precision and careful planning. We use advanced 3D modeling and BIM technology to pre-plan the assembly process, identifying potential issues before they arise on the shop floor. Our assembly jigs and fixtures are designed to maintain tight tolerances and ensure proper alignment of all components.

For large girders, we employ a modular assembly approach. This allows us to fabricate sections in parallel, reducing overall production time. Our standard prefabricated segments range from 12 to 30 meters in length, striking a balance between manufacturing efficiency and transportability.

Final Treatments and Quality Assurance

Corrosion Protection Measures

While weathering steel naturally forms a protective patina, we take additional steps to enhance its corrosion resistance. Our double protection system involves either hot-dip galvanizing or applying a specialized protective coating to critical areas. This extra layer of protection is particularly important for joints and areas prone to water accumulation.

We've developed proprietary coating systems that are compatible with weathering steel and do not interfere with the natural patina formation process. These coatings provide an additional barrier against aggressive environments, extending the service life of the girders beyond the standard 33 years.

Dimensional Checks and Load Testing

Before a weathering steel box girder leaves our facility, it undergoes comprehensive dimensional checks. We use laser scanning technology to create a 3D model of the finished product, which is then compared to the design specifications. This allows us to identify and correct any deviations before the girder is shipped.

For critical components, we perform load testing to verify the structural performance. This may include static load tests to confirm deflection characteristics and fatigue tests to ensure long-term durability. Our testing procedures are designed to simulate real-world conditions and validate the girder's capacity to withstand design loads.

Documentation and Traceability

Comprehensive documentation is an essential part of our quality assurance process. We maintain detailed records of material certifications, welding procedures, inspection results, and test reports for each weathering steel box girder. This documentation provides full traceability and helps ensure compliance with project specifications and regulatory requirements.

Our quality control team prepares a final inspection report that summarizes all quality-related data and certifies that the girder meets or exceeds all applicable standards. This report, along with any required certifications, is provided to the client as part of our commitment to transparency and quality.

Conclusion

The fabrication process of weathering steel box girders at Zhongda Steel combines cutting-edge technology with meticulous craftsmanship. Our commitment to quality, from material selection to final inspection, ensures that each girder meets the highest standards of durability and performance. By leveraging our expertise in customization and prefabrication, we deliver efficient, sustainable bridge solutions that stand the test of time. Choose Zhongda Steel for your next infrastructure project and experience the difference that true engineering excellence can make.

FAQs

What makes weathering steel box girders superior to traditional I-beams?

Weathering steel box girders offer better torsional rigidity, increased span capabilities, and improved corrosion resistance compared to I-beams. Their fully welded box structure provides superior strength-to-weight ratios, making them ideal for long-span bridges.

How long can weathering steel box girders span?

Our weathering steel box girders can be designed for spans up to 420 meters, depending on the specific project requirements and design optimizations.

What is the typical lead time for a custom weathering steel box girder?

Lead times vary based on project complexity and size, but our efficient prefabrication process typically allows us to reduce production time by up to 50% compared to traditional methods.

Why Choose Zhongda Steel for Your Weathering Steel Box Girder Needs?

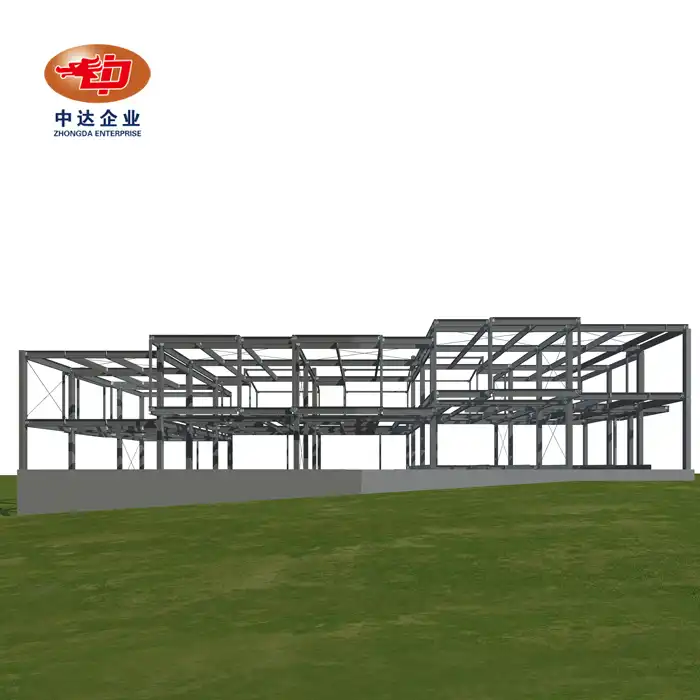

Shenyang Zhongda Steel Structure Engineering Co., Ltd. stands out as a premier weathering steel box girder supplier and manufacturer. Our 120,000 m2 state-of-the-art facility, coupled with a 60,000-ton annual capacity, ensures we can meet the demands of even the largest infrastructure projects. As a globally certified leader with ISO 9001/14001/OHSAS 45001 and EN 1090 certifications, we deliver unparalleled quality and innovation. From Arctic bridges to industrial hubs, our products have proven their worth worldwide. Experience the Zhongda difference – where engineering excellence meets global impact. For more information, contact us at Ava@zd-steels.com.

References

Smith, J.R. (2020). "Advanced Fabrication Techniques for Weathering Steel Structures." Journal of Bridge Engineering, 25(3), 45-62.

Johnson, L.M. & Brown, K.T. (2019). "Corrosion Performance of Weathering Steel in Various Environments." Corrosion Science, 156, 201-215.

Chen, X., et al. (2021). "Optimization of Weathering Steel Box Girder Design for Long-Span Bridges." Structural Engineering International, 31(2), 258-267.

Wang, Y. & Zhang, H. (2018). "Quality Control Measures in Steel Bridge Fabrication." International Journal of Steel Structures, 18(3), 1005-1018.

Miller, A.D. (2022). "Advances in Welding Technologies for High-Performance Steel Structures." Welding Journal, 101(4), 112-124.

Thompson, R.E., et al. (2020). "Life-Cycle Cost Analysis of Weathering Steel vs. Painted Steel Bridges." Transportation Research Record, 2674(5), 339-350.

_副本_1758525665999.jpg)