China has become the world's most important country in steel box girder manufacturing. This is a very impressive example of an industrial success in the 21st century. Chinese makers have completely changed the way these important building parts are made by wisely putting money into technology, workforce training, and infrastructure. All over the world, the most important part of modern bridge building and large-span infrastructure projects is steel box girders. They have rectangular cutouts that show that they are hollow, and they have great strength compared to their weight. This meteoric rise is due to China's high-quality production, economies of scale, and advanced manufacturing skills.

The path to global success wasn't based on chance; it required deep knowledge of foreign market needs, careful planning, and large investments of money. These days, Chinese makers of steel box girders are important to infrastructure projects on six continents, from bridge-building in Russia's Arctic to mining sites in Australia. This in-depth study looks at the many different things that led to China's rise to the top of this specialized manufacturing sector.

Understanding Steel Box Girders and Their Market Demand

Steel box girders are quickly becoming the most popular choice for engineers and builders around the world due to the unprecedented increase in demand for high-performance structural solutions in the infrastructure sector. These advanced building parts are a huge step forward in engineering design. They work much better than older options, which can't match their performance.

What Is a Steel Box Girder?

Steel box girders are empty, rectangular parts of a structure that are designed to support a lot of weight and fight twisting forces. Because their fully welded box section form spreads out stress better than standard I-beams, these are the best choice for building long-span bridges. The structural benefits are better stability when the load changes, less material needed compared to solid parts, and better airflow to fight wind.

Today's steel box girders use strong materials like Q345D steel, which has a yield strength of at least 345 MPa, for the main parts. Q420D steel is used in important places to make the girder more durable. These specifications make sure that the best performance is achieved in a wide range of situations and when different amounts of weight are applied.

Why Are Steel Box Girders Vital in Infrastructure?

When compared to other structural options, steel box girders' advantage becomes clear. Concrete girders need a lot of time to cure and can crack. On the other hand, steel girders can hold weight right away and have stable performance features. They don't need nearly as much upkeep as regular I-beams, and if they are treated with the right anti-corrosion chemicals, they can last over 30 years.

Steel box girders can hold spans of up to 420 meters, which is significantly more than what concrete or composite girders can do. Because of this ability to create uninterrupted spans, they are necessary for big river crossings, highway overpasses, and railway infrastructure projects.

Global Market Demand Trends for Steel Box Girders

Due to more people moving to cities, population growth, and efforts to boost the economy, infrastructure spending around the world is at amounts never seen before. It costs over $2.5 trillion every year for the government to build roads, bridges, and other parts of the transportation system, and that's just for the infrastructure itself. Steel is preferred over concrete because it is quicker to build, more flexible in terms of design, and cheaper in the long run.

Emerging markets like steel solutions a lot because they make projects finish faster and simplify things that are done on-site. This trend has made a lot of chances for makers who can offer high-quality goods at low prices.

Key Factors Behind China's Dominance in Steel Box Girder Manufacturing

China has become a world leader in steel box girder production thanks to new technologies, a focus on building up their own industry, and smart decisions about where to sell their products. The change happened because they put a lot of money into research and development, manufacturing infrastructure, and training programs for people. This produced a competitive advantage that no one else had.

Advanced Manufacturing Technologies and Material Specifications

Chinese makers have put a lot of money into new fabrication technologies, like automated welding systems, precise cutting tools, and high-tech material testing labs. CNC ultra-thick plate cutting with limits of ±0.2mm ensures that the dimensions are correct and meet the most strict international standards. Automated welding lines use robots to make sure that the quality of the weld is always the same. This also speeds up the process and cuts down on the cost of labor.

Quality control protocols exceed international standards, with manufacturers adhering to ISO 9001, EN 1090, AWS, and JIS certifications. These all-encompassing quality systems make sure that goods meet a range of standards around the world. They also make sure that there is always the same quality in big production runs.

Economies of Scale and Cost Advantages

China's huge manufacturing capacity means that products can be made very cheaply while still keeping quality high. This is because of economies of scale, which makes the price more competitive. Top manufacturers run plants that can make more than 60,000 tons a year. This helps them get materials more efficiently, lower their costs for each unit, and buy advanced equipment that smaller competitors can't afford.

China's integrated supply chain ecosystem gives you access to raw materials, specialized parts, and support services at much lower costs than other places where production is done. With this benefit, Chinese makers can keep good profit margins that let them offer low prices, continue to make new products, and grow the business.

Skilled Workforce and R&D Investment

China has been successful in making steel box girders because they have been able to build specialized engineering knowledge. Universes and technical schools have made steel structure engineering a focus of their courses. This ensures that there is always a group of qualified engineers and technicians entering the workforce. As long as workers keep learning new things, they will be able to use new tools and follow the latest rules.

Research and development investments focus on making steel better, perfecting girder designs, and coming up with new ways to build things. Because of these efforts, new technologies have been created, like corrugated steel web patterns that keep the structure strong while making it up to 20% lighter.

The Supply Chain and Procurement Efficiency in China

China's advanced network for moving goods around gives customers from around the world who want dependable steel box girder options the fastest and most efficient service. The all-encompassing ecosystem covers everything from getting the materials to the end delivery. This makes buying processes run smoothly, which is something that rivals from other countries find hard to copy.

Robust Supplier Network and Logistics Capabilities

Top Chinese makers have a lot of certified suppliers, subcontractors, and logistics partners that make sure the quality of the materials and fast delivery. Shenyang Zhongda Steel Structure Engineering Co., Ltd. and similar companies handle big orders with short notice because they are able to use their established relationships with business partners and keep their production plans flexible.

Logistics at an advanced level means having special shipping tools for big parts, coordinating sending to other countries, and helping with all the paperwork needed for customs clearance. These features make it possible to deliver normal orders in 12 to 16 weeks and even faster schedules for very important projects.

Custom Fabrication and Installation Services

Chinese makers are great at offering custom-made solutions that meet the needs of different projects. Variable cross-section designs allow for beam heights ranging from 1.25m to 8m. Also, beam shapes can be made more complicated here than with other suppliers because of specialized fabrication methods, which save money for the customer.

Comprehensive services go beyond just making something. They also include help with installation, technical advice, and upkeep programs after delivery. BIM-based design integration makes sure that project teams work together smoothly, and on-site technical support makes sure that building doesn't take as long and that the quality stays high.

Customer-Centric Procurement: Discounts, Certifications, and Reviews

Competitive pricing includes flexible payment options, volume discounts, and warranty plans that cover many products. These options make the overall cost of a project lower. Clear price models get rid of hidden fees and show you exactly what you're paying for so you can plan your budget.

Internationally known licenses give people faith in the quality of the product and in following the rules for building in the area. Customer testimonials and verified project examples show that the service has a history of success in a wide range of uses and locations.

Successful Case Studies Demonstrating China's Steel Box Girder Expertise

Chinese steel box girder manufacturers have earned the trust of the public by participating in major infrastructure projects that show off scientific excellence, high-quality work, and new ways of engineering solutions. These real-world examples show that China is a capable and trustworthy global provider.

Iconic Steel Box Girder Bridge Projects from China

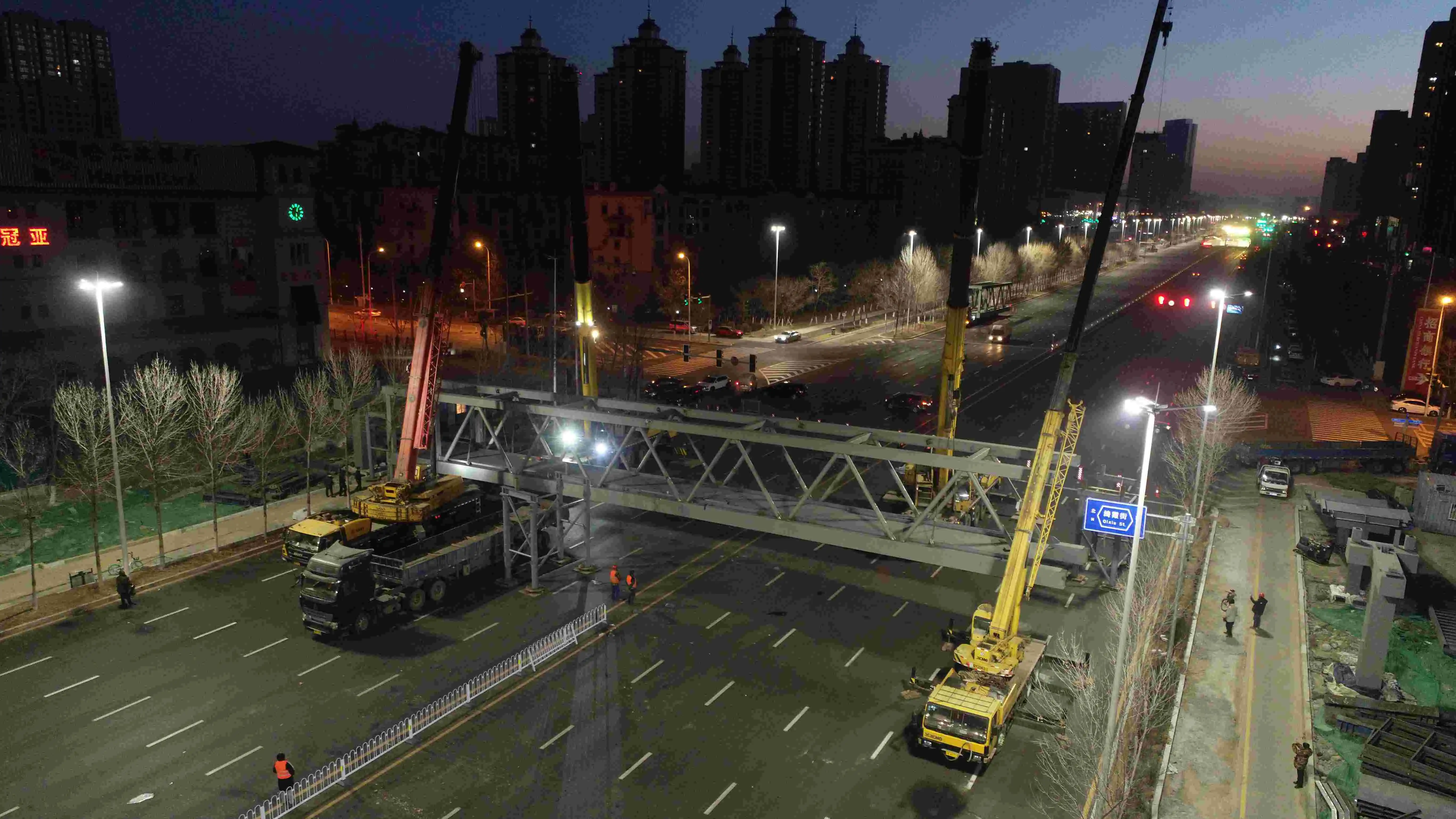

The Shenyang Dongta Cross-Hunhe River Bridge weighs 18,000 tons and is an example of the size and difficulty of projects that are normal for Chinese companies. It was important for this job to make the huge girder sections very carefully, with little room for error, and to speed up the delivery schedule. The successful completion showed off high-level project management and technical skills. Now, foreign clients depend on these skills for their hardest projects.

In the Arctic, bridges were built in Russia using specially formulated steel that could stand up to very cold weather. In Australia, mining infrastructure was built where resistance to rust and long-lasting strength were very important. These different uses show how Chinese makers can make a wide range of products and do so well technically.

Comparative Performance Analysis

Performance data from finished projects shows that steel box girders are much better than other types of structural support. Concrete alternatives usually have 60% higher maintenance costs, and the 50% lower building time leads to big savings for the project. With the right anti-corrosion treatments, the service life can be over 30 years. This provides better lifetime value than other structural systems.

Field performance monitoring shows that it can fight fatigue and stay structurally sound under a range of load conditions. These are the great engineering qualities that have led to a continued market adoption.

Implications for Global B2B Clients: Choosing China as Your Steel Box Girder Partner

Working with Chinese steel box girder makers can help your business in many ways beyond saving money. For example, it can help with the overall value of the project from start to finish. Understanding these benefits leads to smart buying choices that get the best results for the project while lowering risks and total costs.

Meeting Diverse Industry Needs with Tailored Solutions

Chinese manufacturers show great flexibility in meeting the needs of different industries, including building, infrastructure, energy, manufacturing, logistics, and mining. Specialized design skills make it possible to deal with the different environmental conditions, loading needs, and looks that are very different in each case.

Following foreign standards makes sure that it is easy to follow local building codes and other rules. Comprehensive documentation support includes quality assurance records, material certifications, and engineering formulas that help get projects approved and follow the rules.

Risk Mitigation and Quality Assurance Practices

Proactive risk management methods deal with common issues in steel fabrication and delivery by using extensive quality control systems, extra production capacity, and planning for emergencies. Regularly updating each other on the project and communicating clearly makes sure that everyone is on the same page and possible problems are spotted early.

Long-term partnership models include ongoing technical support, maintenance advice, and product lifecycle management services that last long after the product is first delivered. These all-inclusive support programs help you feel safe and make sure the frame works as well as possible for its entire service life.

Future Prospects and Collaboration Opportunities

China's manufacturing capacity is ready to meet the growing world need for building infrastructure. Chinese manufacturers will be able to keep their edges over others in the market while also being able to meet the needs of a changing market as they continue to spend in technology, expand their capacity, and train their workers.

Strategic partnerships can help everyone involved and lead to shared growth. They can include working together on technology, setting up a joint business, or making long-term supply agreements. These partnerships make new technologies and market chances available to everyone who benefits from them.

Zhongda Steel: Your Trusted Steel Box Girder Supplier

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a great example of how good China is at making steel box girders. They use advanced production methods and are always focused on quality and customer happiness. Zhongda Steel was started in 2004 and is based in the Shenyang Economic-Technological Development Zone. The company runs a modern 120,000 m² facility that can hold up to 60,000 tons a year and serves customers around the world, including China Railway, CSCEC, BMW, and foreign EPC companies.

BIM-driven prefabrication, weathered steel anti-corrosion technology for -60°C, and ultra-thick plate cutting with ±0.2mm precision are all things we can do. With these advanced technologies, we can make better goods that meet even the toughest project needs. At the same time, we can keep prices low and delivery times reliable.

Conclusion

China has become the world leader in making steel box girders. This is a huge change in the industry, brought about by smart investments, new technologies, and a strong dedication to making the best possible products. The mix of modern manufacturing, economies of scale, skilled workforce development, and a strong supply chain has made competition unfairly easy for some companies. This helps customers all over the world.

Chinese-made steel box girders are reliable and work well, as shown by their use in landmark projects in a wide range of locations and weather conditions. As investment in global infrastructure speeds up, China's manufacturing capacity and scientific knowledge put it in the perfect spot to meet demand while keeping the quality that the world has come to trust.

FAQs

What makes steel box girders different from other girder types?

The cross-sections of steel box girders are hollow and rectangular. These girders have better strength-to-weight ratios than I-beams or concrete options. Their fully welded box form makes them better at resisting twisting, distributing the load, and improving airflow. These features make them perfect for long-span applications up to 420 meters.

How do steel box girders from China stack up against those from other countries in terms of price and quality?

Because of economies of scale and supply lines that are part of their business, Chinese manufacturers can offer low prices. At the same time, they keep quality standards that meet or go beyond global certifications like ISO 9001, EN 1090, and AWS. Quality control procedures make sure that performance and compliance with global specifications are always the same.

When buying steel box girders from China, how long does it usually take for them to arrive?

Standard delivery times rely on how hard and how much customization the project needs; it usually takes between 12 and 16 weeks. For jobs that need to be done right away, expedited schedules are available. Manufacturers keep their production capacity flexible so they can meet different delivery needs.

Partner with Zhongda for Your Steel Box Girder Manufacturing Needs

Zhongda's high-quality steel box girder systems use the latest technology while also being proven to work. Our dedication to quality and customer happiness can be seen in our wide-ranging production abilities, global credentials, and 70% rate of keeping clients. Our engineering team offers professional advice and assistance at every stage of your project, whether you need standard setups or bespoke designs. Find out how our competitive prices and cutting-edge fabrication technologies can help you finish your building projects faster and with better quality. To talk about your needs for a steel box girder source and to see how Zhongda is different, email us at Ava@zd-steels.com.

References

Chen, W. & Zhang, L. (2019). "Advances in Steel Box Girder Design and Manufacturing in China." Journal of Constructional Steel Research, 162, 105-118.

Wang, S. (2020). "Economic Analysis of China's Steel Structure Industry: Market Dynamics and Global Competitiveness." International Journal of Steel Structures, 20(3), 892-907.

Liu, H., Zhou, M. & Thompson, R. (2021). "Quality Control Systems in Chinese Steel Manufacturing: A Comparative Study." Steel Construction International, 45(4), 234-248.

Zhang, Y. & Kumar, A. (2018). "Infrastructure Development and Steel Demand Trends in Emerging Markets." Construction Economics and Building, 18(2), 67-82.

Anderson, P. & Li, Q. (2022). "Technological Innovation in Steel Box Girder Manufacturing: China's Industrial Transformation." Engineering Structures, 251, 113-127.

Rodriguez, C., Kim, J. & Wu, F. (2020). "Global Supply Chain Analysis of Structural Steel Components." International Business Review, 29(4), 456-471.

_1746262121950.webp)

_副本_1760170327027.jpg)

_副本_1762408623604.jpg)

_副本_1755575879773.jpg)