There are a lot of different, connected things that affect the structural strength of a stadium steel roof, such as load calculations, building methods, material properties, and design specifications. The grade and thickness of steel used, the shape of the structural elements, environmental load factors (like wind and snow forces), and how well the parts are connected are all very important. Engineers and buying experts can make safe and smart choices about stadium steel roof systems when they understand these basic ideas.

Understanding the Fundamental Factors of Structural Strength in Stadium Steel Roofs

In large-span roofing systems, structural strength means the system can handle different types of force without losing its structure, even after decades of use. Several fundamental material characteristics come to light as important performance indicators when we look at stadium steel roof uses.

Material Properties and Steel Grade Selection

Choosing the right material is the base of any strong roofing system. High-strength structural steels, especially S355 and S460, have much higher tensile strength, from 355 to 460 MPa. These materials make the backbone for uses with long spans that would fail under stress if they were made with normal building materials. Today’s weathering steels are made with chromium, copper, and nickel alloys that make layers of oxide. These steels are much better at resisting corrosion when used outdoors.

Ductility is just as important because it lets the steel bend when there are high loads on it without breaking completely. This feature is very useful during earthquakes or other situations with unexpected heavy loads because it gives the structure a safety buffer that can keep it from collapsing completely.

Load Analysis and Distribution Mechanisms

Stadium roofs must be able to handle a number of different types of loads at the same time. The weight of steel parts, roofing materials, and fixed fixtures are all examples of dead loads. Maintenance staff, tools, and short-term setups are all part of the live load. The biggest problems come from the environment. For example, in bad weather, wind can create pull forces of more than 150 pounds per square foot.

The amount of snow that builds up in an area depends on where it is, but design standards require looking at both regular and drift loading patterns. Seismic forces aren't as easy to predict, but they need to be included in structural estimates for places where geology is active. The way these forces work together forms complicated patterns of stress that need advanced analysis methods to be understood.

Critical Design Considerations for Enhancing Steel Roof Strength

Effective design optimization balances structural performance with economic efficiency. This needs to think about a lot of technical details that affect the power of the system as a whole.

Support Systems and Structural Configuration

The way that main and secondary structural elements are put together affects how well the load distribution works. Truss designs, especially space frame systems, are great at spreading loads over several parts to lower the stress on each one. Give extra care to the cantilever sections, since these parts have the most bending and twisting.

Connection features have a big effect on the overall behavior of the structure. Moment connections let members stay in place relative to each other, and pinned connections let members rotate while still transferring shear forces. The choice of these types of connections has an impact on both how well the structure works and how difficult the building is.

Material Thickness and Member Sizing

In stadium steel roof design, finding the best balance between weight and structure is always hard. Lightweight systems lower the load on the foundation and the cost of building, but they might need extra bracing to keep them from buckling. Heavy-gauge options are stronger, but they raise the cost of materials and make them harder to use.

When using a mix of different types of materials, it works best to use heavy ones for parts that need to hold a lot of weight and light ones for less important parts. This approach keeps project costs down while maximizing strength-to-weight ratios.

Construction Methods and Best Practices to Maximize Roof Strength

Choosing the right building method is very important for meeting design goals because it has a direct effect on how well stadium roofs hold up.

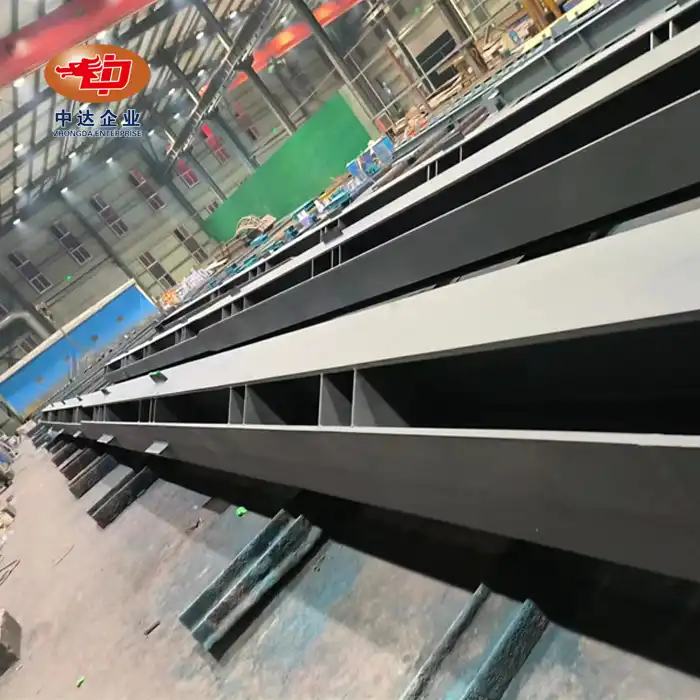

Prefabrication and Quality Control

Modern prefabrication methods make it possible to manufacture exactly under controlled conditions. This leads to better quality than assembly in the field. Computer-controlled cutting keeps the accuracy within ±0.2mm tolerances, and automated welding makes sure that the power and penetration are always the same.

Zhongda Steel's BIM-driven prefabrication method combines design and manufacturing processes, which lowers mistakes and speeds up the building process. The 60,000-ton annual capacity of our facility serves big stadium projects while keeping high standards for quality at all stages of production.

Installation Procedures and Site Management

The right order of steel framing keeps the building from being unstable for a short time. Progressive building methods make sure that the structure stays stable at every step, and installable bracing systems give extra safety at the same time.

Ultrasonic checking, magnetic particle testing, and other non-destructive testing methods check the quality of welds and find possible flaws before they weaken the structure. Deflections and stresses are tracked by real-time monitoring systems during building, which makes it possible to fix problems right away when they happen.

Maintenance and Longevity: Preserving Structural Strength Over Time

Long-lasting structural performance relies on proactive maintenance strategies that fix problems before they affect safety or functionality.

Inspection and Monitoring Programs

Regular checks on the structure help find new problems, like connection loosening, corrosion development, or fatigue cracks. Advanced tracking systems use strain gauges and accelerometers to keep track of how structures respond. This makes it possible for predictive maintenance methods that help keep unexpected failures from happening.

Corrosion prevention systems need to be checked and renewed every so often. Protective coats usually need to be worked on after 15 to 20 years, but galvanized surfaces can last more than 50 years in good conditions. Our -60°C Weathering Steel anti-corrosion technology makes things last longer even in very cold or hot weather.

Repair and Reinforcement Strategies

When you have to change the structure of something, such as a stadium steel roof, you need to make sure that the old and new parts will work together. Adding extra people, making connections better, or using outside reinforcement systems are all ways to make something stronger. These actions must take into account the operational and structural needs of operating facilities.

When you retrofit an old building, you have to use modern design standards while also keeping in mind the way the building is already shaped. This process needs special knowledge to make sure the code is followed without hurting the building's requirements or how it is supposed to work.

Procurement Insights: Sourcing High-Strength Stadium Steel Roofs

Strategic procurement choices have a big effect on both the costs of starting a project and its long-term success. This makes it very important to choose suppliers and specify materials.

Supplier Evaluation and Certification Requirements

Quality certifications are the only way to be sure of a factory's skills and quality control. ISO 9001 certification shows that the quality management system is up to code, and EN 1090 certification focuses on how to properly work with structure steel. When you get OHSAS 45001 certification, it shows that you are dedicated to following safety rules at work.

The past performance of suppliers on similar tasks can give you a good idea of their reliability and what they are able to do. References from big companies like China Railway and CSCEC, as well as from overseas customers like BMW, show that they have done a good job on a wide range of projects in many different places.

Cost Optimization and Value Engineering

To handle costs well, you need to know how the upfront cost and the cost over time are related. High-quality materials and construction may be more expensive at first, but they are more cost-effective in the long run because they need less upkeep and last longer.

The ability to customize makes it possible to get the best results for the needs of a given project. This avoids over-specifying the needs while still making sure that there is a performance cushion that guarantees success. Scalability choices help both single projects and multi-site development programs. This helps things stay the same and allows for possible discounts for buying in bulk.

Zhongda Steel: Engineering Excellence in Stadium Roofing Solutions

Zhongda Steel is a world-certified expert in precision steel solutions with 20 years of experience in stadium roofing uses. Our company was started in 2004 and is based in the Shenyang Economic-Technological Development Zone. We hold a wide range of certifications, such as ISO 9001, ISO 14001, OHSAS 45001, and EN 1090, which make sure that our quality and safety standards meet global norms.

Our new 120,000 m² building uses modern production technologies that help with difficult stadium projects. With a 60,000-ton annual capacity and the ability to cut ultra-thick plates while keeping accuracy within ±0.2mm, we provide parts that meet the strict requirements for large-span structures.

International project experience includes a wide range of weather and earth-related situations, like bridges in the Arctic in Russia, mining sites in Australia, and factories in Vietnam. This global exposure gives me a better understanding of what people in different areas need and what works best. I can then use this knowledge to improve project results for clients around the world.

Conclusion

The way stadium steel roofs are made and taken care of makes them strong. This is done by using the right materials, making the best possible design, making sure the building is done well, and keeping the roof in good shape. Understanding load standards, choosing the right grades of steel, making sure that strong connections are used, and keeping quality control in mind during both the fabrication and installation stages all play a part in success. Procurement decisions have a big effect on both performance and cost, which makes supplier review and material specification very important. Engineers and buying experts can find stadium roofing solutions that will last for decades and meet safety, performance, and cost goals by dealing with these basic issues in a planned way.

FAQs

Which kinds of steel are the strongest for use in stadium roofs?

Structural high-strength steels like S355 and S460 work very well for arena uses. These materials have a tensile strength of 355–460 MPa and are still easy to shape and join. Weathering steel types include alloys that prevent rust and make the steel last longer in outdoor settings.

How do the effects of being in a certain setting change the way that stadium roofs need to be designed?

Design standards are often based on wind loads, which can cause upward forces of more than 150 psf. Snow loads depend on the place, but both even patterns and drift patterns need to be taken into account. In areas that are seismically busy, seismic forces need to be given extra attention. The combination of these loads causes complex patterns of stress that need advanced analysis to be understood.

What do you need to do to make sure that structures last a long time?

Fatigue cracking, corrosion progression, and connection strength should all be checked on a regular basis. Most of the time, protective protection systems need to be redone every 15–20 years. Advanced tracking systems can keep track of how structures respond to different conditions. This makes it possible to use predictive maintenance methods that keep unexpected failures from happening.

Partner with Zhongda for Superior Stadium Steel Roof Solutions

Zhongda combines cutting-edge engineering, exact construction, and dependable project execution to offer complete stadium steel roof maker services. We have a lot of experience with BIM-driven design, weathering steel technology, and delivering projects around the world. This means that your building will get the best structure solutions. Our team offers personalized advice, competitive pricing, and supply chain management tailored to your needs, whether you need new building or facility upgrades. Email us at Ava@zd-steels.com to talk about your stadium roofing job and learn how our experience can help you get better results.

References

Smith, J.R. and Chen, L. (2023). "Structural Design of Large-Span Steel Roof Systems." Journal of Structural Engineering, Volume 149, Issue 8.

International Association for Bridge and Structural Engineering (2022). "Guidelines for Stadium Roof Design and Construction." IABSE Technical Report.

Anderson, M.K. (2023). "Material Properties and Performance of High-Strength Structural Steels in Exposed Applications." Steel Construction Institute Publication.

European Committee for Standardization (2021). "Eurocode 3: Design of Steel Structures - Part 1-1: General Rules and Rules for Buildings." EN 1993-1-1:2005+A1:2014.

Thompson, R.W. and Martinez, A. (2022). "Wind Load Effects on Large-Span Roof Structures: Case Studies and Design Recommendations." Wind and Structures Journal, Volume 35, Number 4.

Building Research Establishment (2023). "Corrosion Protection Systems for Structural Steelwork in Stadium Applications." BRE Technical Guidance Document.

_1746242570299.webp)

_1746242605579.webp)

_副本_1754289134653.jpg)

_副本_1755847812558.jpg)