Engineering excellence must be balanced with local requirements, climate considerations, and regulatory compliance when customizing steel stadium structures for foreign markets. With modern steel stadium structure solutions, architects and contractors can build top-notch venues that work well in a wide range of geographic and culture settings. The key is to understand how to change the rules of structure engineering so that they work in each country while still being safe, cheap, and effective. This all-encompassing strategy guarantees that your steel stadium structure will perform at its best and last the longest, regardless of whether it is built for tropical or arctic temperatures, earthquake zones, or hurricane-prone areas.

Understanding the Core Principles of Steel Stadium Structure Customization

The key to successful stadium customization is to combine strong technical basics with the needs of the area. It is very important to know how much weight different places can hold when building structures that need to be able to handle different kinds of environmental stress, like snow in the north or wind at the coast.

Structural Integrity and Environmental Adaptation

Seismic activity and fire risks are environmental dangers that need special engineering methods to deal with. In areas with a lot of earthquakes, modern steel fabrication methods make structures more flexible. These methods use modular links that can move with the ground but keep the steel stadium structure stable. Fire resistance rates get the REI 120 designation through intumescent coating technologies, which makes sure that they meet safety standards around the world.

Climate-Responsive Design Features

To make spectators more comfortable and the system more efficient, the way of insulating and ventilating must change with the temperature where it is located. Better airflow systems and UV-resistant coatings are necessary in warm areas. On the other hand, places in the Arctic need better insulation and weathering steel that can work in temperatures as low as -60°C.

Regulatory Compliance and Code Integration

Following rules that are specific to each country affects the choice of materials and building methods in big ways. Compliance with EN 1090 and AISC makes sure that projects meet both European and North American standards. This makes the process of taking on projects across countries easier while keeping the quality the same. This method of dual certification makes it easier for global contractors and government bodies to get what they need.

Comparing Structural Options to Optimize Customization Choices

Choosing the right materials is very important for the success of stadium design. Compared to older options like concrete, metal, and wood, steel is more affordable, lasts longer, and can be used in a wider range of designs, making it the most popular choice.

Steel Versus Traditional Materials

Steel has much better fire and earthquake protection, which are very important benefits in areas where risk is high. Even though most concrete buildings take 24 to 36 months to build, steel stadiums can be built in just 12 to 18 months. This 40% decrease in time is very important for deadlines based on events. This speed-up is due to pre-fabricated modular systems that make it possible to manufacture elsewhere and quickly put everything together at the spot.

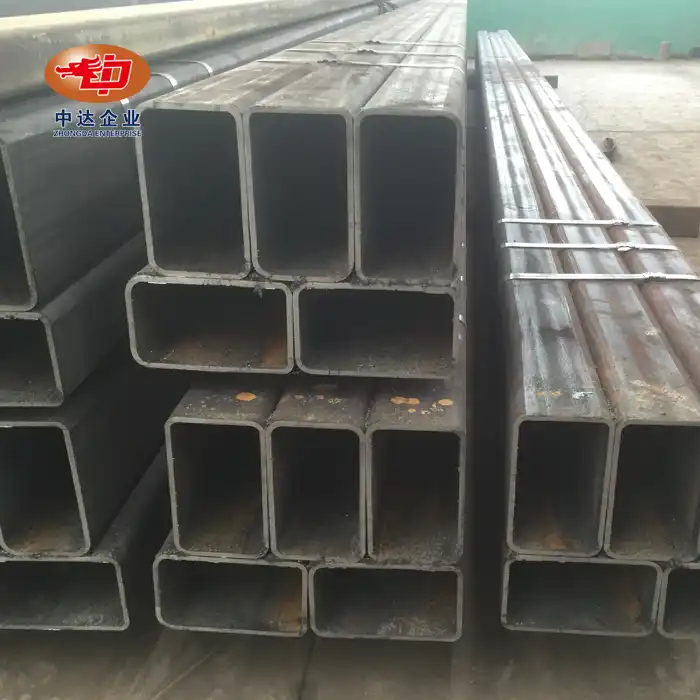

Advanced Steel Technologies and Protective Systems

Knowing the right kinds of steel and protective coatings to use will make sure that everything works well in all kinds of temperatures and corrosive settings. Components that are hot-dip galvanized according to ISO 1461 standards will be protected from rust for a long time. Also, parts that are certified under ASTM A992 will be structurally reliable and come with full mill test records that allow you to trace where they came from. Thanks to these technological breakthroughs, steel stadium structures can span up to 300 meters without needing to be supported in the middle. This gives people a clear view of what is below.

Step-by-Step Process to Customize Your Steel Stadium Structure

A systematic approach that starts with a full evaluation of the site and goes all the way through to installation and approval is needed for successful customization.

Initial Assessment and Design Planning

The customization process starts with a close look at the area weather, geology, building codes, and the needs of the user. This study helps with design choices about structural load rates. These must be higher than what is needed for wind speeds up to 200 km/h and also work with seismic zones up to VIII on the Mercalli scale.

Engineering and BIM Integration

Using advanced Building Information Modeling (BIM) for design and engineering changes helps make sure that ventilation, insulation, and fire safety features are all part of the plans in an exact and compliant way. BIM-driven prefabrication makes it possible to make exact parts and work with local engineering experts to make sure that everything follows the rules.

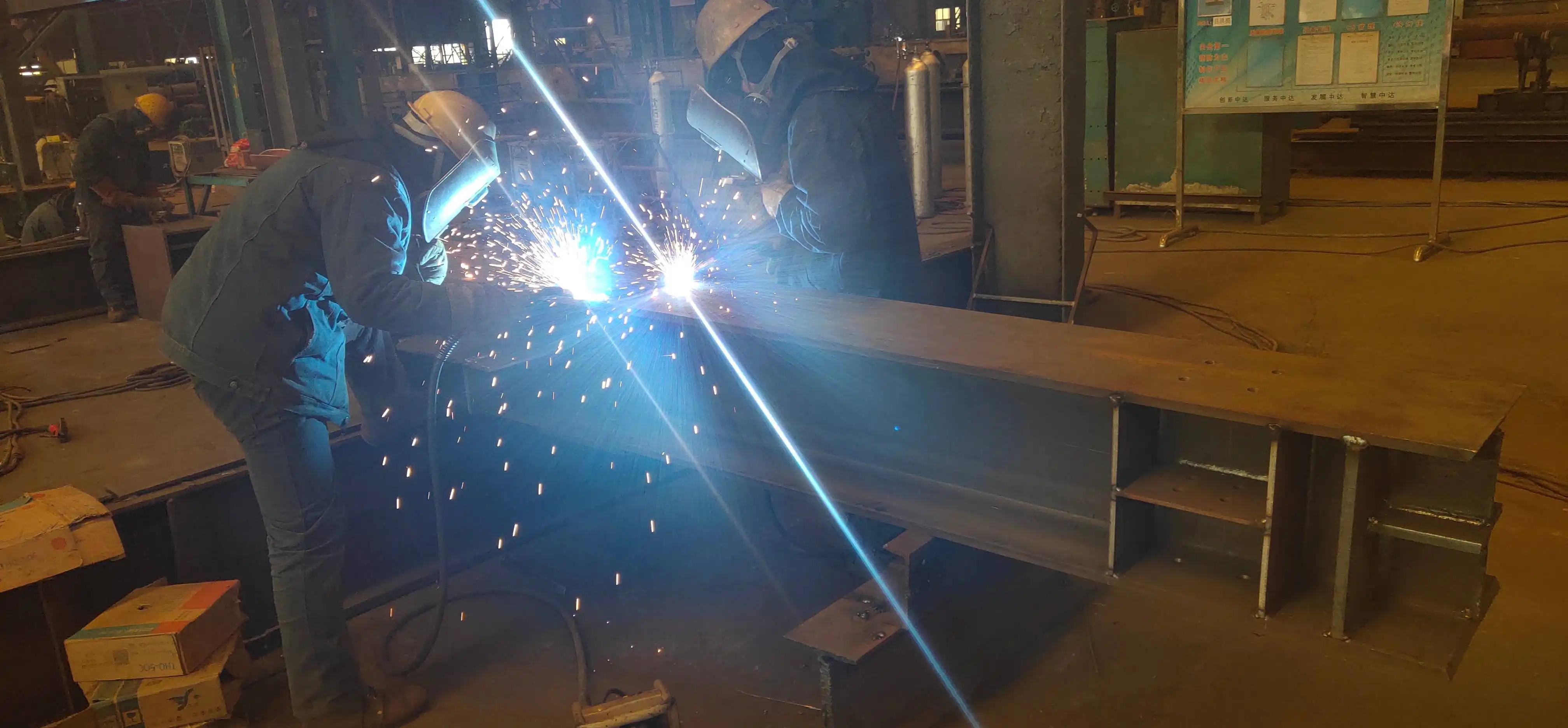

Procurement and Supply Chain Management

When you buy something, it's important to choose suppliers who are certified and have experience in quality assurance and foreign logistics. Using 100-ton bridge cranes and the newest construction methods, custom manufacturing techniques make it possible to build custom steel parts with a level of accuracy that can't be achieved with standard construction methods. Modular parts make it easier for global supply lines to work quickly and cheaply, which helps with every stage of a project.

Maintenance and Lifespan Optimization for Customized Steel Stadiums

To get the most life out of a stadium, you need to be proactive about fixing things and make plans based on the stadium's location and how it is used.

Environmental Challenge Management

Regional issues like heat, exposure to salt, and pollution from factories need specific ways of caring for the environment. Routine checks focus on important structural points like joints, links, and protective coatings to keep them from breaking down. Advanced weathering steel anti-corrosion technology better protects against damage from the climate and lowers the need for long-term maintenance.

Modular Maintenance Advantages

Smart designers used corrosion-resistant coatings and modular parts so that system improvements or replacements can be easily done without changing the overall steel stadium structure. This method protects the worth of the investment and makes sure that the stadium stays safe and works well even when it is in use for a long time. Maintenance schedules change based on the local environment and how often the stadium is used. This makes sure that resources are used in the best possible way and that operations are not interrupted.

Addressing Procurement and Partnership Needs for Global B2B Clients

When businesses internationally buy goods from each other, they need to carefully rate their suppliers so they can work with qualified, experienced makers that can provide environmentally friendly products with a guarantee.

Supplier Credentials and Quality Assurance

Understanding a manufacturer's qualifications and quality certifications helps avoid risks in a project and makes sure that it meets global standards. ISO 9001/14001/OHSAS 45001 standards show that you are dedicated to managing quality, protecting the environment, and keeping people safe at work. These credentials are especially useful when working on complicated foreign projects that need to follow exact technical specifications and make sure that deliveries happen on time.

Custom Fabrication and Installation Support

Custom fabrication services must be able to clearly explain and give thorough technical documents that show they know the rules for each country. Installation coordination across borders is easier with full after-sales help to deal with problems at the site in the right way. These methods help procurement processes run smoothly, build trust, and provide stadium solutions that are compliant with the rules and don't cost too much for both government and business customers around the world.

Conclusion

Steel stadium structure customization for foreign markets necessitates a delicate balancing act between technical prowess and localization strategies. To be successful, one must know the needs of the area, choose the right materials and protective systems, use systematic design processes, and work with makers who have a lot of experience. With modern steel manufacturing methods, builders can meet a wide range of rules and regulations and still build things quickly. With careful planning, strong partnerships, and proactive upkeep strategies, customized steel stadiums provide amazing value, safety, and performance in markets around the world. These venues last for decades and serve their communities well.

FAQs

How do local climate factors impact the design of the steel stadium structure?

The climate has a big impact on the choice of materials, the need for protection coatings, ventilation systems, and insulation methods. In tropical areas, you need better defense against corrosion and UV rays. In cold areas, you need weathering steel technologies and better insulation. It's important to think about earthquakes when designing structural connections and foundations. It's also important to think about wind when designing the general shape of a structure and how to make sure it stays in place.

In comparison to concrete options, what benefits do steel stadium structures offer?

Steel structures allow for more customization, faster building, better earthquake protection, and more design options. Modular prefabrication with steel parts instead of concrete can cut on-site building time by as much as 40%. Also, steel is more cost-effective in the long run because it can be recycled, is easier to change for future updates, and has lower needs for the base because of its lighter weight.

How long will it take to bring and set up the custom steel stadium?

The timeline for a project depends on how complicated the design is, how much customization is needed, and how shipping works. Most timelines are between 12 and 18 months and include the design, fabrication, delivery, and installation stages. Modular prefabrication systems let you make parts at the same time and cut down on the time needed for on-site building. At the same time, BIM integration speeds up the design review process and stops too many change orders during construction.

Zhongda Steel: Your Premier Steel Stadium Structure Supplier

For projects ranging from Olympic facilities to community sports complexes, Zhongda Steel is your go-to provider for steel stadium structure, providing world-class venues that combine speed, safety, and scalability. ISO 9001-certified bridge cranes with 100-ton capacity and other cutting-edge tools are used in our factories to make custom steel parts exactly how you want them, in a way that can't be done with older building methods.

Our factory covers 120,000 m² and makes 60,000 tons every year. We help projects around the world with BIM-driven prefabrication and specialized weathering steel anti-corrosion technology. Our work around the world, from building bridges in Russia to setting up mining equipment in Australia, shows how we always offer top-notch engineering no matter what the rules or weather are like.

Our team offers full support, from helping you create the right modular prefabricated parts for quick installation to coordinating the complex custom fabrication needed for unique architectural plans. Ready to make your dreams come true? For personalized advice, email us at Ava@zd-steels.com to learn how our steel stadium structure solutions can help you meet your performance goals, stay on budget, and finish your project on time.

References

American Institute of Steel Construction. (2019). Steel Construction Manual, 15th Edition. AISC Publications.

European Committee for Standardization. (2021). Eurocode 3: Design of Steel Structures - Part 1-1: General Rules and Rules for Buildings. EN 1993-1-1:2005+A1:2014.

International Association for Sports and Leisure Facilities. (2020). Guidelines for Sports Facility Design and Construction Standards. IAKS Technical Commission Report.

Building and Construction Authority Singapore. (2022). Code of Practice for Structural Use of Steel 2022. BCA Technical Standards.

American Society for Testing and Materials. (2021). Standard Specification for Structural Steel Shapes. ASTM A992/A992M-21.

International Organization for Standardization. (2018). Hot Dip Galvanized Coatings on Fabricated Iron and Steel Articles - Specifications and Test Methods. ISO 1461:2009.