Getting factory-direct steel box girders changes the way infrastructure is built by cutting out the middleman and giving builders direct access to top-notch building materials. This buying method follows international standards while cutting costs, improving quality control, and speeding up project timelines. Steel box girders made through factory-direct channels can be customized in more ways, have clearer prices, and offer more expert support. Because of this, they are the best choice for big building and infrastructure projects around the world.

Understanding Steel Box Girders and Their Role in Modern Construction

When it comes to building modern bridges and other important structures, steel box girders are the very best there is in structural engineering. These basic building blocks use modern metals and exact manufacturing methods to give unbeatable performance in big projects. The closed-box form has great strength-to-weight ratios and better resistance to twisting, making it better than other common structure options.

Superior Structural Performance Through Advanced Design

Today's steel girders use a fully welded box section form that better spreads weight than older I-beam styles. This new piece of engineering makes longer span structures possible while keeping them safe when heavy things are put on them. The empty box shape is the best mix of performance and cost because it uses less material while keeping the same strength. This is what infrastructure experts want.

Material Excellence in High-Strength Steel Applications

Today, steel box girders are made mostly of high-quality Q345D steel, which has a minimum yield strength of 345 MPa and an excellent ability to hold heavy weights. Q420D steel is used in important link places to make them more durable in areas that get a lot of stress. This planned choice of materials makes sure that the construction will work in a range of settings while also passing strict global building codes.

Why Choose Factory-Direct Supply for Steel Box Girders?

The factory-direct buying approach changes the way the supply chain normally works by creating direct ties between makers and end users. This method removes several middle-man price increases and makes sure that everyone can see and hear the discussion at all stages of the project. People who work in procurement get technical knowledge, the ability to customize, and quality testing methods that other sales outlets can't offer.

Significant Cost Advantages Through Supply Chain Optimization

The most common way to buy things can make a project more expensive by 15-25% compared to direct business ties. These saves are due to better transportation planning, lower handling fees, and getting rid of dealer profits. Also, factory-direct providers offer volume-based pricing models that are good for large-scale building projects while keeping prices low for smaller projects.

Enhanced Quality Control and Manufacturing Oversight

Factory-direct vendors use quality control systems that watch over every step of the production process, from checking the raw materials to the final delivery of steel box girder components. Using advanced CNC ultra-thick plate cutting technology allows for exact tolerances of ±0.2 mm, while automatic welding systems ensure consistent joint quality. This rigorous quality control approach simplifies on-site installation and significantly reduces long-term maintenance requirements.

Customization Capabilities for Project-Specific Requirements

Direct maker ties make a lot of different customization choices possible that normal wholesalers can't offer. Variable cross-section designs can handle beam heights from 1.25m to 8m. On the other hand, corrugated steel web choices can cut the weight of the structure by as much as 20% while still keeping it strong. The maximum single-span length that can be supported is 420 meters, which helps the most bold building projects around the world.

Comparing Factory-Direct Steel Box Girders with Other Girder Types

A deep study of performance shows that steel box girders are much better than other structure systems. Box girders regularly outperform plate girders, I-beams, composite designs, and concrete options in a variety of technical measures. It is especially clear how these relative benefits help long-span projects in which the economy of the structure directly affects the overall cost of the project.

Performance Superiority Over Traditional Steel Alternatives

Steel box girders have better load distribution and twisting strength than standard I-beam designs. The closed-section shape offers better side-to-side stability, which means that extra support systems don't have to be used. These systems would make the project more complicated and more expensive. This efficient design makes it possible to have longer spans that don't need extra support while still meeting the safety standards set by the building code.

Advantages Over Concrete and Composite Systems

Steel box girders have lower dead loads, speed up building, and are more flexible for complicated shapes than prestressed concrete options. The prefabrication method allows for quality control in the plant and cuts the time needed for on-site building in half. This early start is especially useful in cities where building time limits affect project planning.

Ensuring Optimal Performance Through Proper Maintenance and Structural Analysis

Long-term performance gains require preemptive repair plans and close tracking of the structure over the entire working life. Suppliers that sell directly to factories offer useful technical help that keeps equipment running longer and cuts down on repair costs. Advanced rust protection systems, like double-layer treatments through galvanizing or specialized paint techniques, can make things last more than 30 years in tough conditions.

Advanced Anti-Corrosion Technologies

Today's steel box girders use advanced methods to protect against rust that blend pickling with high-performance paint treatments. This two-layer method protects the surface from damage by the elements and cuts down on the need for long-term upkeep. The -60°C weathering steel technology was made for use in very cold places, and it is an example of how advanced materials science is used in today's building projects.

Structural Analysis and Load Optimization

Building Information Modeling (BIM) technology and advanced structure analysis tools are used together in modern industry to find the best ways to support weight and use less material. These computer tools can predict exactly how a part will work and find places where stress might build up before it is made. The outcome is an improved structure performance that meets or goes beyond the design requirements and also cuts down on the cost of materials.

Seamless Integration of Factory-Direct Supply into Your Procurement Strategy

In order to successfully work with factory-direct providers, you need to carefully consider their skills, licenses, and support infrastructure. Suppliers with experience in many countries must meet a number of standards, such as ISO 9001/14001/45001, EN 1090, AWS, and JIS. These licenses make people sure that the systems are good and help get approval from tech experts and government agencies around the world.

Global Logistics and Delivery Solutions

These days, factory-direct sellers offer a wide range of shipping options that can be tailored to different project needs and site limitations. Just-in-time building methods are supported by the ability to easily change delivery dates, and safe packing saves parts when they are shipped overseas. Global shipping networks make sure that materials get to faraway job sites quickly and at a low cost.

Technical Support and Engineering Collaboration

Top companies offer a lot of professional help during all stages of a project, from the first planning talks through the end of building and more. Engineering teams work with designers to make sure that their structure solutions are the best possible while still following local building rules and global guidelines. This method of working together on technical projects lowers risk and speeds up the time it takes to plan new projects.

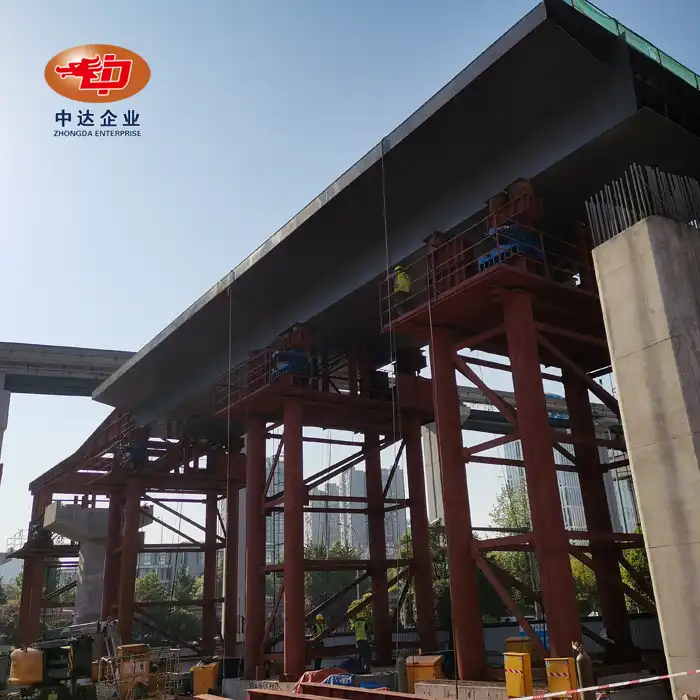

Zhongda Steel: Your Trusted Factory-Direct Steel Box Girder Manufacturer

The city of Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a top factory-direct steel box girder maker. We have been doing great engineering since our start in 2004 over 20 years ago. In the Shenyang Economic-Technological Development Zone, our 120,000-square-meter plant uses high-tech production and strict quality control to make sure our structure solutions are the best in the world.

With cutting-edge CNC tools and automatic welding systems, we can make up to 60,000 tons of product a year. Using BIM in precision manufacturing for building projects makes sure that they are done in 20-30% less time. We have completed many important projects, like the 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge, and have also worked on building projects in other countries.

Zhongda's promise to innovation goes beyond the norm to include specific uses, such as building bridges in the Arctic in Russia, supporting mining equipment in Australia, and building factories across Southeast Asia. Because our engineers have a lot of experience with projects in extreme environments and with cutting-edge anti-corrosion technologies, we have become the most trusted partner for difficult building projects around the world.

Conclusion

Getting factory-direct steel box girders is a new way of buying infrastructure that clearly helps with cost, quality, and speed. The advanced production, customizability, and great technology support create value propositions that can't be matched by standard sales methods. As the needs of infrastructure projects change in terms of longer lifespans, quicker building times, and better sturdiness, it becomes more and more important for factory-direct relationships with trusted makers. It's clear from the data that using this buying approach leads to better project results and lower overall costs for the lifetime of the project.

FAQs

What cost savings can organizations expect from factory-direct steel box girder procurement?

Getting goods straight from the factory instead of through normal shipping routes usually lowers the overall cost of a project by 15% to 25%. These saves are due to eliminating markups, optimizing transportation, and using volume-based price systems that are good for both big and small building projects.

How do steel box girders compare to concrete alternatives in construction timeline and maintenance requirements?

Steel box girders cut about 50% off of the time needed to build something because they can be made in parts that are easy to put together. Long-term upkeep needs are lower with improved anti-corrosion treatments that last more than 30 years with little work needed.

What customization options are available through factory-direct suppliers for project-specific requirements?

The best factory-direct makers give a range of beam heights (from 1.25m to 8m), web choices with beams that stay straight, and the ability to span up to 420 meters. They also offer beam shapes with different cross-sections and a 20% drop in weight for curved webs. With BIM interaction, you can do exact customizations and still make things quickly.

Partner with Zhongda for Your Next Infrastructure Project

Zhongda's factory-direct steel box girder solutions bring 20 years of technical experience and new production technology together to change your infrastructure projects. Our all-encompassing method provides individualized building fixes, adheres to global norms, and speeds up the time needed to complete projects. As a trusted steel box girder provider, we help with everything from planning to the end of building and beyond.

Enjoy the benefits of working directly with an internationally qualified maker that has completed major projects in a range of areas around the world. Because we are dedicated to quality, innovation, and our clients' success, we have formed long relationships with top building companies, government contractors, and engineering consultants around the world. To talk about your project needs and see how Zhongda's factory-direct method can help your next building project, email us at Ava@zd-steels.com.

References

American Institute of Steel Construction. "Design Guide 2: Design of Steel and Composite Beams with Web Openings." Third Edition, Chicago: AISC, 2018.

Chen, Wai-Fah and Lian Duan. "Bridge Engineering Handbook: Construction and Maintenance." Second Edition, CRC Press, 2014.

European Committee for Standardization. "EN 1993-2: Eurocode 3 - Design of Steel Structures - Part 2: Steel Bridges." Brussels: CEN, 2006.

Galambos, Theodore V. and Adrian E. Surovek. "Structural Stability of Steel: Concepts and Applications for Structural Engineers." John Wiley & Sons, 2008.

National Steel Bridge Alliance. "Steel Bridge Design Handbook: Construction." Highway Structures Design Handbook, Volume 18, Federal Highway Administration, 2015.

Taly, Narendra. "Highway Bridge Superstructure Engineering: LRFD Approaches to Design and Analysis." CRC Press, 2014.