China has great industrial skills and advanced production technologies. It also offers reasonable prices and has a history of providing high-quality construction materials. Because of this, countries around the world are increasingly getting their infrastructure steel from China. Chinese companies such as Zhongda Steel have become reliable sources for global infrastructure projects, offering specialized options that meet strict international standards and are cheaper than the ones offered by other countries' companies.

Understanding Infrastructure Steel and Its Global Demand

What is Infrastructure Steel? Key Types and Properties?

Infrastructure steel is a type of structural material that is used in very big building projects like roads, trains, bridges, and public buildings. These materials are not like regular building steel; they are tested and made in very strict ways to make sure they work well in harsh circumstances. The main ones are high-strength low-alloy steel, weathering steel, and corrosion-resistant kinds made for certain environmental problems.

Today's infrastructure steel has much higher tensile strength, usually between 345 and 690 MPa. This lets builders make lighter, stronger buildings. These materials are also easier to weld and make, which is important for complicated building plans and quick construction schedules.

Uses and Benefits of Infrastructure Steel in Modern Infrastructure Projects

For building bridges, railways, and highway overpasses, specific steel types are very important to the transportation infrastructure. Power production plants use high-quality steel for things like transmission poles, substations, and green energy setups. Logistics centers and port facilities need steel buildings with long spans that can hold up big machinery and automatic systems.

The benefits go beyond making the structure more sound; they also include shorter building times, safer gaps, and less need for upkeep. Advanced steel materials keep working well and don't break down in the surroundings.

Steel Standards and Grades Essential for Global Infrastructure Requirements

Infrastructure steel specs are governed globally by international standards like ASTM A572, EN 10025, and JIS G3106. Grade 50 steel (with a minimum yield strength of 345 MPa) is the standard for most highway and bridge uses. For tougher structural needs, higher grades like Grade 65 (with a 450 MPa yield strength) are used.

Chinese makers follow these global standards and also meet the requirements for the CE marking in Europe and AISC guidelines in the United States. This agreement makes sure that no matter where you are, you can easily be a part of foreign projects.

Overview of Infrastructure Steel Durability and Corrosion Resistance

Weathering steel is a big step forward in building materials. It forms protected layers of metal that stop rust without needing to be coated again. Zhongda Steel's unique -60°C Weathering Steel Anti-corrosion Technology is an example of this kind of innovation. It lets buildings survive the harshest Arctic weather without losing their shape.

The galvanized and zinc-aluminum covered choices give extra security in the sea and industrial areas. With these surface treatments, the service life gets extended to 50-75 years under normal conditions. This lowers the costs for infrastructure owners and means they don't have to do as much upkeep.

Comparing China's Infrastructure Steel Supply with Global Competitors

Infrastructure Steel vs Construction Steel: Differentiation in Global Markets

Infrastructure steel needs to meet better performance standards than steel used in construction more generally. While building steel is mostly about basic structural needs, infrastructure grades have to deal with changing loads, exposure to the elements, and earthquakes for decades of use. Chinese producers have focused on these difficult uses and have built up metalworking skills that go beyond the usual qualities of building steel.

Infrastructure steel requires more rigorous testing methods, such as Charpy impact testing at low temperatures and fatigue resistance evaluation under cycle loading conditions, which goes to quality control processes.

Comparing Infrastructure Steel from China and Other Leading Manufacturers

China's ability to produce steel tops 1 billion tons a year, which is about 57% of the total output worldwide. This level of production allows companies to buy the newest technology and keep the quality the same on all of the big sales. European and American makers make high-quality goods, but they work on much smaller scales, which makes their prices per unit higher.

When you look at the quality, you can see that Chinese companies always meet foreign standards while also making things faster and being more flexible with special orders. Computer-controlled processes are used in advanced production facilities to make sure that the dimensions are correct within ±0.2mm. This meets or goes beyond the standards used around the world.

Cost, Quality, and Sustainability: China's Competitive Edge in High-Strength Steel

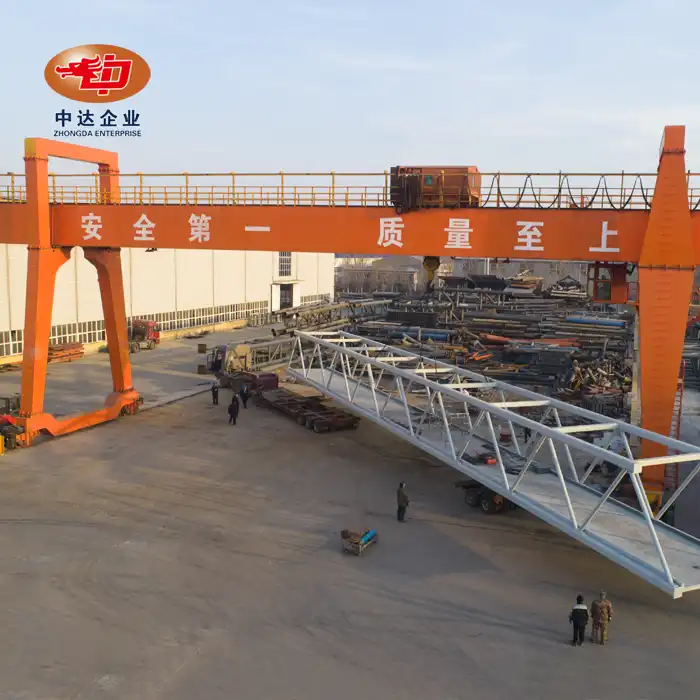

China's ability to get ahead in business comes from linked supply lines, improved technology, and economies of scale. Zhongda Steel's 120,000 m² complex is an example of a manufacturing facility that processes raw materials and makes finished products all in one place. This saves money and helps with quality control at every stage of production.

Using energy-efficient electric arc burner technology, salvaged materials, and carbon impact reduction projects are all ways to help the environment. Chinese makers keep their costs low compared to standard providers while having similar or better effects on the environment.

Case Studies: Successful International Projects Using Chinese Infrastructure Steel

Chinese weathering steel that can handle big changes in temperature and exposure to water was used in the Kerch Strait Bridge, which goes from Russia to Crimea. This 19-kilometer-long building shows that Chinese infrastructure steel can be trusted to work well in tough conditions.

Australian mines have been able to get processing equipment frames and conveyor support structures made in China to work quickly and cheaply, with no problems with safety or performance. These projects show that Chinese infrastructure steel is of high quality and can be relied on for difficult industry uses.

Why China is the Preferred Choice for Infrastructure Steel Procurement?

A Lot of Manufacturing Space and High-Tech Steelmaking

China uses the most advanced ways to make steel in the world, with basic oxygen furnaces, electric arc technology, and continuous casting systems. Modern plants meet strict quality standards with automatic tracking and control systems. These plants produce more than 10 million tons a year, per plant.

New breakthroughs in metallurgy are only possible because companies keep putting money into research and development. For example, Chinese makers are coming up with new ways to make and mix alloys. With BIM-driven prefabrication, parts can be made exactly how they are shown in the digital model. This helps the project stay on schedule by cuttng the time needed for on-site installation.

Competitive Pricing and Economies of Scale Influencing Procurement Decisions

Chinese producers can offer reasonable prices without lowering quality or service because they make infrastructure steels in large amounts. Chinese sellers are appealing to buying teams that are focused on saving money because they can get even better prices on big projects when they buy in bulk.

Economies of scale aren't just about making things; they also include optimizing transportation, managing supplies, and providing expert support. This all-encompassing method lowers the overall cost of the project and makes sure that there is always enough building material on hand during the construction stages.

Comprehensive Supplier Network and Efficient Logistics Solutions in China

China's wide network of suppliers gets raw materials, does specialty processing, and gets finished products to customers. With the help of well-known shipping lines and transportation partnerships, goods can be sent to places around the world on time and at a low cost.

Today's ports and shipping systems make it easy for big steel goods to get from factories to markets around the world. This benefit in logistics makes the arrival time more predictable and helps with project preparation for clients from other countries.

High Compliance with International Steel Standards and Certifications

Chinese makers have a lot of different kinds of licenses. For example, they have ISO 9001 for quality management, ISO 14001 for environmental standards, and EN 1090 for approvals in their own industries, like structure steelwork. Regular checks by people outside the company make sure that the business keeps following rules from around the world that may change.

Statistical process control, material tracking, and thorough testing methods are all parts of quality assurance systems. These steps make foreign customers sure they can count on the products to work well and be the same every time.

Navigating the Procurement Process: How to Source Infrastructure Steel from China

Key Considerations When Choosing Chinese Infrastructure Steel Suppliers

When you want to work with a good source, you need to look at their knowledge, quality standards, and how they make their products. It is safer to buy things from companies that have been around a long time and has experience with similar applications because they are sure to work well. Technical knowledge of certain types of steel and how they can be used should be in line with what the project needs.

Getting to know a business by visiting it and checking out its facilities can give you a lot of information about how they make things and how they make sure that everything is high quality. For complicated building projects, directly talking to engineering teams helps figure out how much expert knowledge and problem-solving skills they have.

Bulk Purchase and Delivery Options for European and American B2B Clients

For normal steel goods, container shipping is the cheapest way to transport them. It usually takes between 15 and 25 days for shipments to reach major ports in Europe and America. Break bulk shipping can handle large structure parts that are longer or wider than the containers they are normally shipped in.

Buyers can save money on shipping costs and balance risk better when delivery terms are flexible and include FOB, CIF, and DDP choices. When you have a good relationship with a freight forwarder, customs clearance and transfer to the end location go smoothly.

The online shopping sites, lead times, and price transparency

It usually takes 4 to 8 weeks to make standard infrastructure steel goods, based on how many are ordered and how they are supposed to be made. Custom-made options might take longer to get, up to 10-12 weeks, but they will work better for certain uses.

Honest price lists show the cost of materials, the fee for handling, and the cost of shipping without any secret costs. During the buying process, digital tools allow people to track orders and communicate in real time. This helps with project planning and teamwork.

Ensuring Reliability: Understanding Supplier Certifications and Reviews

Due research that is thorough and complete checks on financial security, business licenses, and export qualifications. Project files and customer examples show how well someone has done in the past instead of how well they say they can do.

Third-party certification services check the skills and production powers of suppliers on their own. These tests make buying safer and make sure that the project needs are met and the quality standards are followed.

Company Introduction and Product & Service Information

Overview of Our Expertise in Supplying High-Quality Infrastructure Steel

Founded in 2004 and based in the Shenyang Economic-Technological Development Zone, Zhongda Steel has provided outstanding precision steel services for twenty years. Our businesses, certified around the world, have ISO 9001, ISO 14001, OHSAS 45001, and EN 1090 certifications, which show our dedication to quality and safety standards.

Our modern building covers 120,000 square meters and has high-tech machines for making goods that can handle a yearly 60,000-ton capacity. Some of the specialized skills are BIM-driven prefabrication, cutting ultra-thick plates with ±0.2mm accuracy, and unique Weathering Steel Anti-corrosion Technology at -60°C, which is meant for extreme conditions.

Customized Solutions Tailored for Diverse Global Infrastructure Projects

Our specialty is making unique infrastructure steel for a wide range of uses, such as Arctic bridges, mining equipment, and industrial hubs. Our engineering team works with customers to make sure that material specs, structure designs, and assembly methods are the best possible fit for each project's needs.

Complex shapes and exact precise assembly are possible with advanced manufacturing. This cuts down on building time and project total efficiency at the job site. Computer-controlled cutting and shaping tools make sure that all product lines have the same level of consistency in their dimensions.

Commitment to Quality Assurance, Sustainable Practices, and Customer Support

Quality assurance covers all parts of our business, from choosing the right materials to the final review and delivery. Mechanical property proof, physical inspection, and surface quality rating are all part of comprehensive testing methods.

Using less energy when making things, recycling, and programs that cut down on waste are all examples of sustainable practices. Our customer support team helps with tech issues, gives advice on projects, and offers ongoing service for the entire life of the product.

How to Initiate Inquiry and Cooperate with Our Professional Sales Team?

Our knowledgeable sales team knows the specific needs of building projects and helps people buy what they need at every stage of the process. First meetings help people understand the details of the job, when it needs to be done, and how good it needs to be.

Working together on project planning makes sure that the needs of the design and the skills of the manufacturing are in line with each other. During the project lifecycle, regular contact and progress updates keep everyone on the same page and make it possible to solve problems before they happen.

Conclusion

China's infrastructure steel supply is so big because it has improved production, low prices, and a good reputation in global markets. Zhongda Steel is an example of the construction industry's dedication to quality, creativity, and customer service while meeting the tough needs of today's building projects. China is the most popular place for buying workers around the world because of its wide range of suppliers, good shipping options, and compliance with global standards. As infrastructure development grows around the world, Chinese producers are still in the best spot to provide the high-quality steel that is needed to build the important infrastructure systems of the future.

FAQs

What are the key differences between infrastructure steel and construction steel?

Infrastructure steel needs to meet higher performance standards, such as better resistance to stress, defense against rust, and long-lastingness in different weather conditions. These products have to pass tougher quality tests compared to regular building steel. Infrastructure apps also need to be certified and follow international technical rules.

How does China ensure the quality and durability of its infrastructure steel products?

Statistical process control, material tracking, and third-party testing proof are all parts of the broad quality management systems that Chinese companies use. Automated tracking systems are used in advanced production sites to make sure that the qualities stay the same during the whole manufacturing process. ISO 9001 and EN 1090 are examples of international standards that ensure higher quality by regularly checking compliance.

What are typical lead times and pricing factors when buying infrastructure steel from China?

It usually takes 4 to 8 weeks to make standard goods and up to 12 weeks for custom built solutions. Specifications for steel grades, order sizes, surface treatments, and shipping times are all factors that affect the price. The cost of shipping depends on the location, the shipping method, and the amount of goods. For normal items, sending by container is the cheapest way to go.

Contact Zhongda Steel for Premium Infrastructure Steel Solutions

Zhongda Steel's proven knowledge and state-of-the-art manufacturing skills can change your next building project. Our team focuses on providing tailored infrastructure steel options that are better than the quality standards used around the world, all while keeping prices low. Having worked with customers from around the world, such as China Railway, CSCEC, and BMW, for twenty years, we know what it takes to build modern infrastructure. To talk about your project's exact needs and learn why top infrastructure steel makers trust Zhongda as their partner, email us at Ava@zd-steels.com.

References

World Steel Association. "Steel Statistical Yearbook 2023: Global Steel Production and Trade Analysis." Brussels: World Steel Association, 2023.

American Institute of Steel Construction. "Specification for Structural Steel Buildings: AISC 360-22." Chicago: AISC, 2022.

European Committee for Standardization. "Hot Rolled Products of Structural Steels: EN 10025-2:2019." Brussels: CEN, 2019.

McKinsey Global Institute. "Infrastructure Productivity: How to Save $1 Trillion a Year." McKinsey & Company, 2023.

International Association for Bridge and Structural Engineering. "Use of High Performance Steel in Bridge Construction: Technical Guidelines." Zurich: IABSE, 2022.

China Iron and Steel Association. "Development Report on China's Steel Industry: Quality and Innovation Trends." Beijing: CISA Publishing, 2023.