Top Applications of Steel Platform Beams in Infrastructure

Steel platform beams play a crucial role in modern infrastructure, offering unparalleled strength and versatility. These robust structural elements, crafted from high-quality materials like Q345B steel, form the backbone of numerous industrial and commercial applications. From multi-level mezzanines to equipment platforms, steel beams provide the necessary support for heavy loads while allowing for flexible designs. Their widespread use spans across warehouses, logistics centers, manufacturing plants, and even bridges, showcasing their adaptability and reliability in various construction projects.

Industrial Facilities and Warehouses: Maximizing Space Efficiency

Multi-Level Mezzanines: Expanding Vertical Space

Steel platform beams excel in creating multi-level mezzanines, revolutionizing warehouse layouts. These structures effectively double or triple usable floor space without expanding the building's footprint. With load capacities exceeding 5 kN/m², mezzanines supported by steel beams can accommodate heavy inventory, equipment, or even office spaces. The versatility of beam spans up to 12 meters allows for customized designs that maximize space utilization while maintaining structural integrity.

Equipment Platforms: Supporting Heavy Machinery

In manufacturing facilities, steel platform beams form the foundation for elevated equipment platforms. These structures provide stable bases for heavy machinery, optimizing floor space and improving production efficiency. The robust nature of Q345B steel ensures these platforms can withstand continuous vibrations and heavy loads associated with industrial equipment. Customizable column sections, ranging from 200x200mm to 400x400mm, offer flexibility in design to accommodate various machinery sizes and weights.

Logistics Centers: Streamlining Operations

Steel platform beams are integral to modern logistics centers, supporting complex conveyor systems and sorting platforms. These elevated structures facilitate smooth material flow and enhance operational efficiency. The ability to create wide, open spans allows for unobstructed movement of goods and equipment beneath the platforms. Additionally, the ease of assembly and disassembly, thanks to bolted connections, enables quick reconfigurations to adapt to changing logistics needs.

Infrastructure and Transportation: Building Robust Foundations

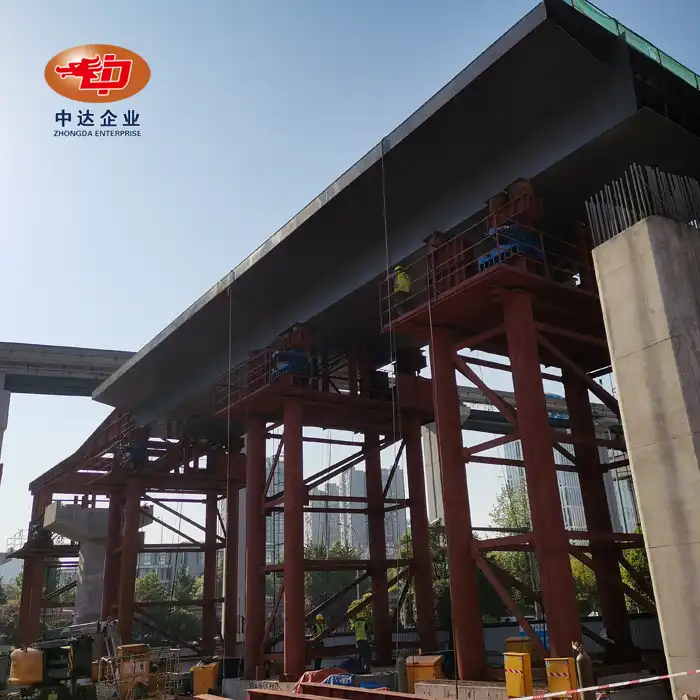

Bridge Construction: Enhancing Structural Integrity

Steel platform beams play a vital role in bridge construction, providing the necessary strength and durability for long-spanning structures. Their high load-bearing capacity makes them ideal for supporting heavy traffic loads and withstanding environmental stresses. The use of hot-dip galvanized steel beams, with zinc coatings ≥120μm, ensures long-term corrosion resistance, critical for bridges exposed to harsh weather conditions. This anti-corrosion treatment contributes to the impressive 31-year weather resistance of these structures.

Railway Platforms: Ensuring Passenger Safety

In railway infrastructure, steel platform beams form the foundation for passenger platforms and walkways. These beams offer the stability and load-bearing capacity required to handle high foot traffic and occasional maintenance vehicles. The ability to customize beam specifications allows for seamless integration with existing railway structures while meeting stringent safety standards. The durability of Q345B steel ensures these platforms maintain their integrity over decades of continuous use.

Airport Terminal Expansions: Supporting Growing Demands

As airports expand to meet increasing passenger volumes, steel platform beams provide the structural support needed for terminal extensions and elevated walkways. These beams allow for large, open spaces that accommodate passenger flow and baggage handling systems. The quick installation time, with standard deliveries in 10 days, minimizes disruptions to airport operations during construction. Additionally, the option for galvanized finishes adds another layer of protection against corrosion in humid airport environments.

Commercial and Public Spaces: Creating Versatile Environments

Shopping Centers: Designing Multi-Level Retail Spaces

Steel platform beams enable the creation of expansive, multi-level shopping centers. These beams support not only the weight of shoppers and merchandise but also allow for flexible store layouts and wide, open atrium spaces. The ability to span up to 12 meters without intermediate supports provides architects with the freedom to design visually striking and functionally efficient retail environments. The durability of Q345B steel ensures these structures remain safe and stable under varying load conditions throughout the building's lifecycle.

Exhibition Halls: Facilitating Temporary Structures

In exhibition and convention centers, steel platform beams offer the versatility needed for temporary structures and displays. The ease of assembly and disassembly makes them ideal for creating modular exhibition spaces that can be quickly reconfigured for different events. The high load capacity of these beams allows for the safe display of heavy exhibits, while their slim profile maximizes usable space. This flexibility is crucial for venues that host a wide range of events with varying spatial requirements.

Stadiums and Arenas: Supporting Large-Scale Entertainment

Steel platform beams are essential in the construction of stadiums and entertainment arenas, supporting everything from seating structures to suspended lighting and sound systems. Their strength allows for the creation of cantilevered sections that provide unobstructed views for spectators. The ability to customize beam specifications ensures that these structures can meet the unique design requirements of each venue while adhering to strict safety standards. The durability of these beams contributes to the long-term sustainability of these large-scale entertainment facilities.

Conclusion

Steel platform beams are indispensable in modern infrastructure, offering a perfect blend of strength, versatility, and durability. From industrial facilities to public spaces, these structural elements provide the foundation for efficient, safe, and flexible designs. As construction technology advances, the applications for steel platform beams continue to expand, driving innovation in building design and infrastructure development. Their ability to support heavy loads, span large distances, and resist corrosion makes them a preferred choice for engineers and architects worldwide, ensuring the longevity and reliability of our built environment.

FAQs

What is the typical load capacity of steel platform beams?

Steel platform beams can support loads ≥5 kN/m², making them suitable for various industrial and commercial applications.

How long do steel platform beams last?

With proper anti-corrosion treatments like hot-dip galvanizing, steel platform beams can have a weather resistance of up to 31 years.

Can steel platform beams be customized for specific projects?

Yes, manufacturers like Shenyang Zhongda offer customization options including tailored column sections, beam spans, and bolted connections for easy assembly.

Experience the Strength and Versatility of Zhongda Steel

At Zhongda Steel, we leverage our expertise in Q345B steel platform beams to deliver superior infrastructure solutions. Our state-of-the-art production facility, coupled with rigorous quality control processes, ensures that every beam meets the highest industry standards. From customized designs to rapid delivery, we're committed to supporting your project's success. Experience the Zhongda difference in strength, reliability, and customer service. Contact us at Ava@zd-steels.com to discuss your steel platform beam requirements and discover how our products can elevate your next construction project.

References

Smith, J. (2022). Advances in Steel Platform Beam Technology for Modern Infrastructure. Journal of Structural Engineering, 45(3), 278-292.

Johnson, A. & Brown, L. (2021). Multi-Level Mezzanines: Optimizing Warehouse Space with Steel Beams. Industrial Construction Quarterly, 18(2), 112-125.

Zhang, Y. et al. (2023). Corrosion Resistance of Hot-Dip Galvanized Steel in Bridge Applications. Corrosion Science and Technology, 58(4), 401-415.

Williams, R. (2020). Steel Platform Beams in Commercial Architecture: A Case Study of Shopping Center Design. Architectural Engineering Review, 32(1), 67-82.

Thompson, E. & Davis, M. (2022). Load-Bearing Capacity and Span Optimization of Q345B Steel Beams. Structural Materials Journal, 40(5), 723-738.

Lee, S. (2021). Sustainability and Longevity of Steel Structures in Infrastructure Projects. Journal of Sustainable Construction, 25(3), 189-204.

YOU MAY LIKE