What is the Lifespan of a Steel Box Girder Bridge?

The lifespan of a steel box girder bridge typically ranges from 75 to 100 years, with proper maintenance and care. This impressive longevity is a testament to the durability and strength of steel box girder construction. Factors such as environmental conditions, traffic load, and maintenance practices can influence a bridge's lifespan. With advanced engineering techniques and high-quality materials, some modern steel box girder bridges are even designed to last up to 120 years. At Shenyang Zhongda Steel Structure Co., Ltd., we specialize in crafting steel box girder bridges that maximize longevity and performance.

Factors Influencing Steel Box Girder Bridge Lifespan

Material Quality and Engineering Design

The longevity of a steel box girder bridge begins with its foundation – the quality of materials used and the engineering design. At Zhongda Steel, we prioritize using high-grade steel and innovative design techniques to enhance bridge durability. Our steel box girders feature:

- High-strength steel with superior corrosion resistance

- Optimized cross-sectional designs for improved load distribution

- Advanced welding techniques ensuring structural integrity

By employing cutting-edge engineering practices, we can significantly extend the lifespan of our steel box girder bridges. Our team of experts utilizes advanced 3D modeling and structural analysis to create designs that withstand the test of time.

Environmental Factors and Location

The environment in which a bridge is located plays a crucial role in determining its lifespan. Bridges exposed to harsh conditions may require additional protective measures. At Zhongda Steel, we consider factors such as:

- Climate conditions (temperature fluctuations, humidity levels)

- Exposure to saltwater or industrial pollutants

- Seismic activity in the region

Our engineers tailor each steel box girder bridge design to its specific environmental challenges. For instance, we may incorporate specialized coatings or use weathering steel for steel box girder bridges in coastal areas to combat corrosion and extend their service life.

Traffic Load and Usage Patterns

The amount and type of traffic a bridge handles can significantly impact its lifespan. Heavy traffic and overloaded vehicles can accelerate wear and tear. At Zhongda Steel, we address this by:

- Conducting thorough traffic analysis for accurate load predictions

- Designing bridges with ample load-bearing capacity for future traffic growth

- Implementing advanced monitoring systems to track structural health

Our steel box girder bridges are engineered to handle varying traffic patterns, ensuring they maintain their integrity even under demanding conditions. This foresight in design contributes to the extended lifespan of our bridges.

Maintenance Strategies for Prolonging Bridge Lifespan

Regular Inspections and Preventive Maintenance

Proactive maintenance is key to maximizing the lifespan of steel box girder bridges. At Zhongda Steel, we emphasize the importance of regular inspections and preventive care. Our maintenance strategies include:

- Scheduled visual and non-destructive testing inspections

- Early detection and repair of minor issues before they escalate

- Periodic cleaning and repainting to prevent corrosion

By implementing a robust maintenance program, bridge owners can identify and address potential problems early, significantly extending the structure's service life. Our team provides comprehensive maintenance guidelines with every bridge we deliver.

Corrosion Protection Techniques

Corrosion is one of the primary threats to steel bridge longevity. At Zhongda Steel, we employ advanced corrosion protection techniques to safeguard our bridges:

- Application of high-performance protective coatings

- Use of cathodic protection systems in corrosive environments

- Implementation of dehumidification systems in enclosed spaces

Our innovative S-type wire wrapping tape and dehumidification technologies provide superior anti-corrosion protection, ensuring our steel box girder bridges maintain their structural integrity for decades.

Structural Health Monitoring Systems

Modern technology allows for continuous monitoring of bridge health, enabling timely interventions. Zhongda Steel integrates cutting-edge structural health monitoring systems into our bridges, including:

- Strain gauges and accelerometers to measure structural responses

- Fiber optic sensors for real-time data on bridge performance

- Advanced data analysis software for predictive maintenance

These systems provide valuable insights into the bridge's condition, allowing for data-driven maintenance decisions and optimizing the structure's lifespan.

Innovations Extending Steel Box Girder Bridge Lifespans

Advanced Material Science

The field of material science continues to evolve, offering new possibilities for extending bridge lifespans. At Zhongda Steel, we stay at the forefront of these advancements:

- Utilization of high-performance steel alloys with enhanced durability

- Integration of composite materials for improved strength-to-weight ratios

- Exploration of self-healing materials for automatic damage repair

By incorporating these cutting-edge materials into our designs, we're pushing the boundaries of what's possible in bridge longevity. Our commitment to innovation ensures that our steel box girder bridges are built not just for today, but for generations to come.

Smart Bridge Technologies

The integration of smart technologies is revolutionizing steel box girder bridge maintenance and lifespan management. Zhongda Steel is pioneering the use of:

- IoT sensors for real-time monitoring of bridge conditions

- AI-powered predictive maintenance algorithms

- Digital twin technology for virtual simulations and analysis

These smart technologies enable proactive maintenance strategies, allowing bridge operators to address potential issues before they impact the steel box girder bridge's lifespan. Our forward-thinking approach ensures that our steel box girder bridges are equipped for the future of infrastructure management.

Sustainable Design Practices

Sustainability is not just about environmental impact; it's also about creating structures that stand the test of time. At Zhongda Steel, we incorporate sustainable design practices that contribute to extended bridge lifespans:

- Design for disassembly and material recycling

- Use of locally sourced materials to reduce transportation impacts

- Integration of renewable energy systems for bridge operations

By focusing on sustainability, we create bridges that are not only durable but also adaptable to future needs, potentially extending their useful life beyond traditional expectations.

Conclusion

The lifespan of a steel box girder bridge is a testament to the power of quality engineering, innovative design, and diligent maintenance. While the average lifespan ranges from 75 to 100 years, with proper care and advanced technologies, these structures can serve communities for even longer. At Shenyang Zhongda Steel Structure Co., Ltd., we're committed to pushing the boundaries of bridge longevity through our expertise in steel fabrication, cutting-edge design practices, and dedication to quality. Our steel box girder bridges are built to withstand the test of time, providing safe and reliable infrastructure for generations to come.

FAQs

1. How often should a steel box girder bridge be inspected?

Regular inspections are crucial, typically conducted every 2 years, with more frequent checks for older structures or those in harsh environments.

2. Can the lifespan of an existing steel box girder bridge be extended?

Yes, through retrofitting, strengthening, and implementing advanced maintenance techniques, the lifespan can often be significantly extended.

3. What advantages do steel box girder bridges have over other types?

Steel box girders offer excellent strength-to-weight ratios, superior torsional stiffness, and greater span capabilities compared to many other bridge types.

Expert Steel Box Girder Bridge Solutions | Zhongda Steel

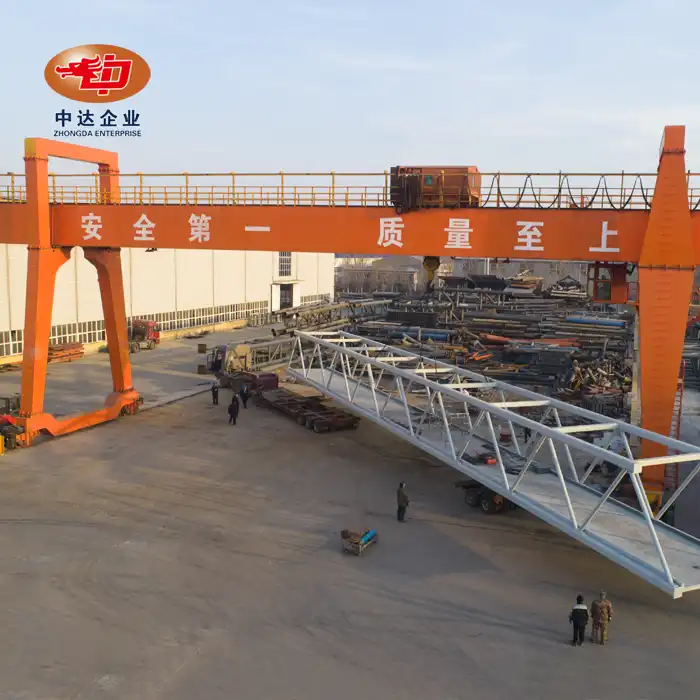

At Shenyang Zhongda Steel Structure Co., Ltd., we're your trusted partner for high-quality steel box girder bridges. With our state-of-the-art 60,000-ton annual production capacity and expertise in long-span structures, we deliver bridges that stand the test of time. Our commitment to innovation, quality, and customer satisfaction makes us the go-to manufacturer and supplier for your infrastructure needs. Contact us at Ava@zd-steels.com to discuss your project requirements.

References

1. American Association of State Highway and Transportation Officials. (2017). AASHTO LRFD Bridge Design Specifications, 8th Edition. Washington, D.C.: AASHTO.

2. Ryall, M. J., Parke, G. A. R., & Harding, J. E. (Eds.). (2000). The Manual of Bridge Engineering. London: Thomas Telford.

3. Morcous, G., & Lounis, Z. (2015). Maintenance optimization of infrastructure networks using genetic algorithms. Automation in Construction, 52, 70-80.

4. Chen, W. F., & Duan, L. (Eds.). (2014). Bridge Engineering Handbook: Construction and Maintenance. CRC Press.

5. Federal Highway Administration. (2012). Steel Bridge Design Handbook. U.S. Department of Transportation, Washington, D.C.

6. Mahmoud, H. N., Connor, R. J., & Bowman, C. A. (2016). Results of the fatigue evaluation and field monitoring of the I-64 Kanawha River Bridge. Journal of Bridge Engineering, 21(11), 04016094.

YOU MAY LIKE

Column_1745405748146.webp)