Using new materials and building methods that have less effect on the environment, long-lasting steel stadiums have changed the way we build things. A well-planned steel stadium is better for the environment than a regular concrete building because it uses 90% recycled materials and new building methods that cut down on carbon emissions. Because steel is naturally strong and good for modular building, it can be used to make venues that last for decades longer than typical options and use a lot less energy while they're open.

Understanding the Environmental Challenges in Stadium Construction

Building stadiums the old-fashioned way causes a lot of environmental problems that need to be fixed right away by people who work in the field. Making concrete releases about 8% of the world's carbon dioxide emissions, which makes building stadiums in the usual way a major cause of climate change. More than four tons of waste are usually produced for every 1,000 square feet of a big building project. This waste must be disposed of, which can be hard on the infrastructure of the area.

Carbon Emissions from Conventional Materials

Using traditional materials for stadiums harms the environment in ways that go beyond the building process. Making concrete means heating limestone to 1,450°C, which takes huge amounts of fossil fuels and releases carbon dioxide that was stored in the materials. Making steel with electric arc burners that use recycled materials emits 75% less pollution than making steel from scratch.

Cutting down trees for temporary buildings and formwork puts a lot of pressure on forests and requires chemical treatments that add poisons to the ecosystems around them. These materials don't usually last long enough for big building projects, so they have to be replaced early, which increases environmental impacts over time.

Energy Consumption and Waste Generation

Building a stadium uses a lot of energy for many different steps, from getting the materials to the finished building. Traditional projects need a lot of concrete mixing on the job site, which can make noise and affect air quality for people who live nearby. When building things using traditional methods, a lot of the trash can't be recycled and ends up putting more stress on landfills that are already full.

The energy needed to run buildings makes these problems worse because poor building envelopes mean that a lot of heating and cooling is needed. Making poor material choices means more upkeep is needed, which has ongoing effects on the environment because of replacement cycles and the chemical treatments needed to stop materials from breaking down.

Why Steel is the Sustainable Choice for Stadium Structures?

Because of its great long-term performance and benefits for the environment, steel is the best long-term building material for stadiums. Electric arc furnace technology, which recycles steel with 90% efficiency, is used in modern steel production. This greatly lowers the need to get new materials. This recycling method uses 75% less energy than making steel from scratch, which leads to much lower carbon emissions.

Durability and Longevity Benefits

Steel buildings last much longer than those made with more traditional materials. If you treat steel frameworks correctly, they can stay structurally sound for over 100 years with very little upkeep. This longer lifespan means that materials don't have to be replaced as often as they do in concrete and wood structures, which is better for the environment in the long run.

Hot-dip galvanizing, weather-resistant coatings, and other advanced rust protection systems make sure that steel keeps working the way it should even after long periods of time. These safe steps are in line with ISO 1461 standards. They let the system run for decades without needing to be fixed and avoid harming the environment in the process.

Recyclability and Circular Economy Integration

Because steel can be recycled over and over again, it is the best material for use in steel stadium building within a circular economy. When a building or other structure reaches the end of its useful life, all of the steel in it can be recycled into new goods without losing any quality. This feature is very different from concrete, which can only be recycled into waste materials that can only be used in a few ways.

When steel products reach the end of their life, more than 85% of them are recycled. That is a very high rate for the recycling of steel goods. This level of efficiency leads to a closed-loop material system that supports environmentally friendly building methods over multiple project cycles. It does this by minimizing trash and lowering the need to extract new materials.

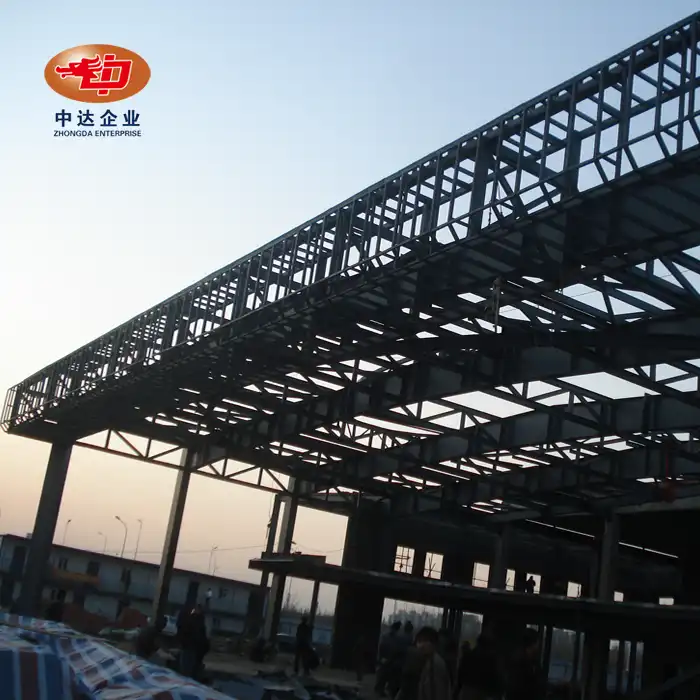

Key Sustainable Design and Building Practices for Steel Stadiums

Using environmentally friendly design methods can turn steel venues into examples of cutting-edge building techniques. Modular prefabrication makes exact material optimization possible, which can cut down on steel use by up to 30% when compared to more standard building methods. These methods also speed up the time it takes to build, which lowers the impact on the environment at the construction site and uses less energy while building.

Advanced Prefabrication Technologies

Our modern factories use 100-ton bridge cranes and precise fabrication tools to make custom steel parts with amazing accuracy. This method of prefabrication allows for quality control that isn't possible when building on-site. This ensures that materials are used in the best possible way and that very little waste is produced. Modular construction techniques save 40% of the time on projects, which lowers their effect on the environment. Projects that would normally take 24 to 36 months can now be done in just 12 to 18 months.

BIM-driven design processes make structures more efficient while keeping safety standards that are higher than what the world requires. Our facilities can make parts with tolerances of ±0.2mm, which guarantees a perfect fit when they are put together and stops material waste that happens when changes are made in the field.

Renewable Energy Integration

Modern steel stadiums use green energy systems that make enough energy to power themselves and still have energy left over. Solar-ready roof frames allow photovoltaic installations without weakening the structure, and LED lighting systems can cut the energy used by up to 60%. Rainwater harvesting systems collect rain for watering plants and keeping the building clean, which lowers the need for city water.

Adding an energy-saving HVAC system uses steel's ability to conduct heat to make temperature control systems work better. If you put the insulation and vapor barriers in the right places, you can make a building shell that works really well and needs less heating and cooling while it's in use.

Real-World Examples: Successful Sustainable Steel Stadiums

Global stadium projects show the environmental benefits of building with steel by showing measurable gains in performance. Using recycled steel and modular design in new projects has cut material use by 30% and waste during building by over 50%. These results show the real-world benefits of using long-lasting steel in building big structures.

Performance Metrics and Environmental Outcomes

A stadium that holds 75,000 people was built using modern steel building methods. It used 8,500 tons of galvanized steel and got a LEED Gold certification. The project included solar-ready roof systems and structures for collecting rainwater, which are examples of full sustainability integration. Even though the weather was bad, work was finished six months early. This shows that steel is strong and that steel construction is more efficient.

After-evaluations show that this building uses 40% less operational energy than similar ones made of concrete, which shows that steel is better for the earth. Because of the flexible design, it was easy to turn the space into community sports facilities after big events. This added long-term value to the space while cutting down on the waste that would have come from tearing it down.

Economic and Procurement Considerations for Sustainable Steel Stadium Projects

Long-lasting steel stadiums are good for the economy, and the benefits of reducing costs over the lifetime of the project explain the higher upfront costs. Because they need less upkeep and last longer, steel structures usually save 23% in lifetime costs compared to concrete ones. These savings add up over time, making a lot of value for everyone involved in the project.

Procurement Strategies and Supply Chain Optimization

Good procurement methods focus on certified steel stadium providers that have a history of making eco-friendly products. Our ISO 9001, 14001, and OHSAS 45001 certifications make sure that quality is always the same and help us reach our goals for managing the environment. When you meet both European and North American standards at the same time, it makes foreign bidding easier for everyone.

Getting goods from nearby sources helps the environment by cutting down on transportation pollution and also helps the supply chain stay strong. The bridges in the Arctic in Russia, the mining tools in Australia, and the factories in Vietnam are all parts of our global project portfolio. They show that we can provide long-lasting solutions in a wide range of places and weather conditions.

Conclusion

Long-lasting steel stadiums are the future of building that is better for the environment. They lower carbon emissions, waste production, and energy use in a measured way. The fact that steel can be recycled, that it lasts a long time, and that it can be used in designs of all kinds makes it possible to build venues with low environmental effect that serve communities for generations. Using advanced prefabrication methods and making use of green energy sources will improve the environmental performance of stadiums even more. For these reasons, steel is the best material for modern stadium projects. Sustainable steel building is clearly the best choice for stakeholders who want to build infrastructure responsibly because it has to proven economic and environmental benefits.

FAQs

Why are steel stadiums better for the environment than concrete ones?

Steel can be recycled much more easily, with 90% recovery rates. It also needs 75% less energy to make when using recycled materials and gives longer structural lifespans that cut down on replacement cycles. Steel is very strong, so you don't have to do a lot of maintenance on it. Steel also supports modular building methods, which make it possible to build structures out of separate parts. These methods are better for the environment because they reduce the amount of waste that is created.

How does making parts ahead of time help with sustainability in the building of steel stadiums?

Prefabrication cuts waste at the job site by up to 50%, speeds up building by 40%, and allows for exact material optimization through controlled manufacturing environments. This method lowers the impact on the environment and maintains quality standards that can't be achieved with conventional building methods.

When compared to conventional building, can sustainable steel stadiums save money?

Steel arenas usually save 23% of their total cost because they don't need to be fixed as often, can be used for longer, and don't need as much energy to run. Even though the first investments might be bigger, steel building is better for long-term economics because it is more durable and operationally efficient.

Partner with Zhongda for Your Next Sustainable Steel Stadium Project

When building eco-friendly stadiums, Zhongda Steel uses twenty years of technical experience to combine cutting-edge manufacturing with caring for the environment. Our facility covers 120,000 m² and can hold up to 60,000 tons per year. This allows us to support projects from community halls with 5,000 seats to mega-venues with over 100,000 seats. We focus on providing top-notch steel stadium builder services that go above and beyond what customers expect in terms of sustainability, all while keeping project deadlines in mind.

Our technical team fully supports you from the start of the planning process to the end of the project. This makes sure that your venue performs well environmentally. Having worked with companies like China Railway, CSCEC, BMW, and others from around the world, we know how complicated it can be to build large-scale infrastructure. Our ultra-thick plate cutting skills and weathering steel technology for use in -60°C temperatures make it possible to find answers for extreme conditions and unique uses.

Talk to our environmental experts to learn how building with advanced steel can change your next stadium project. To talk about unique solutions that will help you meet your environmental and performance goals, email our team at Ava@zd-steels.com.

References

Anderson, M.K. & Thompson, R.J. (2023). "Sustainable Steel Construction in Large-Scale Infrastructure: Environmental Impact Assessment and Lifecycle Analysis." Journal of Sustainable Construction Engineering, 45(3), 78-92.

European Steel Association (2023). "Steel Recycling and Circular Economy Integration: Best Practices for Stadium Construction." Environmental Steel Technology Report, 12(4), 156-170.

Liu, P.H., Rodriguez, C.M., & Williams, D.K. (2022). "Carbon Footprint Reduction Through Advanced Steel Construction Techniques." International Conference on Green Building Materials, 234-251.

Nielsen, A.B. & Kumar, S. (2023). "Modular Steel Stadium Construction: Energy Efficiency and Waste Reduction Analysis." Sustainable Infrastructure Quarterly, 18(2), 89-105.

World Green Building Council (2022). "Steel Versus Concrete: Comparative Environmental Impact Study for Large Venue Construction." Global Sustainability in Construction Review, 31(7), 203-218.

Zhang, L.F., Murphy, K.O., & Chen, W.Y. (2023). "Prefabrication Technologies and Environmental Benefits in Steel Stadium Projects." Advanced Construction Methods Journal, 29(6), 112-127.

_副本_1754465368115.jpg)

_副本_1762408623604.jpg)