There are a number of important things that you should think about when you are choosing structural steel material for your building project if you want to make sure that it works well and saves you money. The quality of the steel types and whether they meet global standards such as ASTM A36 and A992 have a direct effect on the success of a project. Corrosion resistance, strength-to-weight ratios, material composition, and delivery capabilities are basic factors that affect both the short-term results of building and the long-term strength of the structure. Understanding these key factors gives procurement workers the power to make choices that are informed, balance technical needs with budget issues, and keep safety and quality standards high.

Understanding Structural Steel Materials: Properties and Standards

Steel manufacturing has changed a lot over time, making materials that meet the needs of different types of construction in a range of businesses. Modern structural steel encompasses various grades intended for specific load-bearing applications, each having unique mechanical properties that determine their suitability for different projects.

Steel Grade Classifications and Their Applications

ASTM A36 is the most popular grade because it is easy to weld and works well for general building. ASTM A572 is stronger and better for demanding structural needs. ASTM A992 especially targets beam and column applications in high-rise construction. Each grade has different yield strength, tensile strength, and elongation properties that are directly linked to how well the project is expected to do.

The amount of carbon in steel has a big effect on its mechanical qualities. Low-carbon steels are more ductile and easier to weld, but medium-carbon steels are stronger. Adding alloys like manganese, silicon, and copper changes the materials even more, making them better suited for certain situations or structural needs.

International Standards and Compliance Requirements

Compliance with recognized standards ensures material reliability and facilitates smooth procurement processes across global markets. In North America, ASTM specs are most important. In Europe, it's EN standards, and in Asia, it's JIS standards. Understanding these differences helps procurement professionals do a good job with foreign supply chains.

Mill test certificates, chemical composition reports, and mechanical property documentation prove compliance with specified standards. These papers give you the basic quality assurance and traceability that protect against material defects and make sure that all parts of a project follow the rules.

Core Factors for Selecting Structural Steel Material

Choosing the right structural steel material involves a lot of thought about a number of technical and practical factors that affect both the speed of the construction process and the long-term performance of the building.

Mechanical Properties and Performance Characteristics

Yield strength tells you the most stress steel can take before it bends or breaks in a way that can't be fixed, and tensile strength shows you the ultimate load-bearing capacity. These features are directly related to the building code and safety rules that engineers must follow.

Strength-to-weight ratio calculations make the best use of material, which is especially important for lightweight and strong uses. High-strength low-alloy steels work better in situations where weight matters, like bridges and tall building construction. In these cases, lowering the dead weight makes the structure more efficient.

Environmental Resistance and Durability Factors

How resistant a material is to corrosion greatly affects how long it lasts and how much care it needs, especially in difficult environments. Weathering steels form protective oxide layers that make it unnecessary to coat them again and again. This lowers lifecycle costs in applications that are exposed.

Temperature performance changes how materials act in extreme conditions. Some specialized grades of material will keep their mechanical properties in very cold or very hot settings. Knowing these rules makes sure that the right materials are used in the right project settings.

Comparison of Structural Steel with Alternative Materials

Material selection includes comprehensive analysis of available options, comparing performance characteristics, cost implications, and construction efficiency across different materials.

Steel Versus Concrete Performance Analysis

Compared to concrete, structural steel has better torsional strength and allows for faster building. Because of its light weight, steel requires less support from the foundation. This lowers the cost of building and makes it possible to build in areas with difficult soil.

Concrete excels in compressive strength applications and provides natural fire resistance, making it perfect for specific applications like foundations and fire-rated assemblies. But for commercial and industrial projects, steel's ability to be prefabricated and the benefits of modular building are usually more important than concrete's benefits.

Alternative Metal Comparisons

Aluminum provides excellent corrosion resistance and lightweight characteristics but lacks the strength needed for major load-bearing applications. Its higher cost per unit strength makes it economically viable only in specialized applications where weight reduction justifies the premium.

Stainless steel has much better resistance to corrosion, but it is much more expensive, so it can only be used in certain cases where outstanding environmental resistance is needed. Knowing these pros and cons makes it possible to choose the right materials for a project based on cost and other specific needs.

Procurement Considerations for Structural Steel Materials

To ensure project success and risk minimization, structural steel material procurement must carefully consider supplier skills, delivery logistics, and quality assurance processes.

Supplier Qualification and Certification Verification

Honest businesses use full quality management systems that meet ISO 9001 standards. This shows that they use the same quality control methods during production and delivery. Checking welding certificates like EN 1090 makes sure that suppliers can meet the standards of fabrication quality.

The ability to deliver on time and provide long-term help are directly affected by a supplier's financial stability and production capacity. Looking at suppliers' past work on similar projects gives useful information about their ability to meet strict quality standards and project deadlines.

Logistics and Delivery Optimization

Lead time management requires coordination between steel production schedules and building timelines. If suppliers offer flexible delivery options and smart inventory management, they can adapt to changing project needs and avoid delays that cost a lot of money.

Custom cutting and fabrication services are very helpful because they reduce the amount of work that needs to be done on-site and speed up the fitting process. ±0.2mm precision cutting tolerances guarantee that parts fit together correctly and there is less need to change things in the field.

Practical Guide to Evaluating and Buying Structural Steel Materials

Systematic evaluation processes make sure that technical requirements, supplier capabilities, and economic factors that affect procurement choices are all carefully considered.

Technical Requirements Assessment

The project specifications spell out the least amount of material needed for things like performance characteristics, grade designations, and dimensional tolerances. Making detailed technical matrices that show how each provider meets these needs makes it easier to judge each one fairly and lowers the risk of making the wrong choice.

Structural analysis and load calculations find the right section sizes and material grades for different uses. When design engineers work together with procurement experts, they make sure that the materials they choose meet both technical needs and cost goals.

Economic Evaluation Framework

The cost of everything, including possible waste, materials, transportation, and processing, is called total cost accounting. Long-term supply deals and volume pricing can help big projects or building programs with ongoing work save a lot of money.

Value engineering opportunities emerge through collaboration with suppliers who understand project requirements and can suggest alternative materials or manufacturing methods that maintain performance while reducing costs.

Zhongda Steel: Your Trusted Structural Steel Material Partner

Zhongda Steel stands as a globally certified leader in precision steel solutions, offering two decades of manufacturing excellence to projects worldwide. Since 2004, our commitment to innovation and quality has earned certifications including ISO 9001, ISO 14001, and OHSAS 45001, along with EN 1090 welding certification that demonstrates our fabrication capabilities.

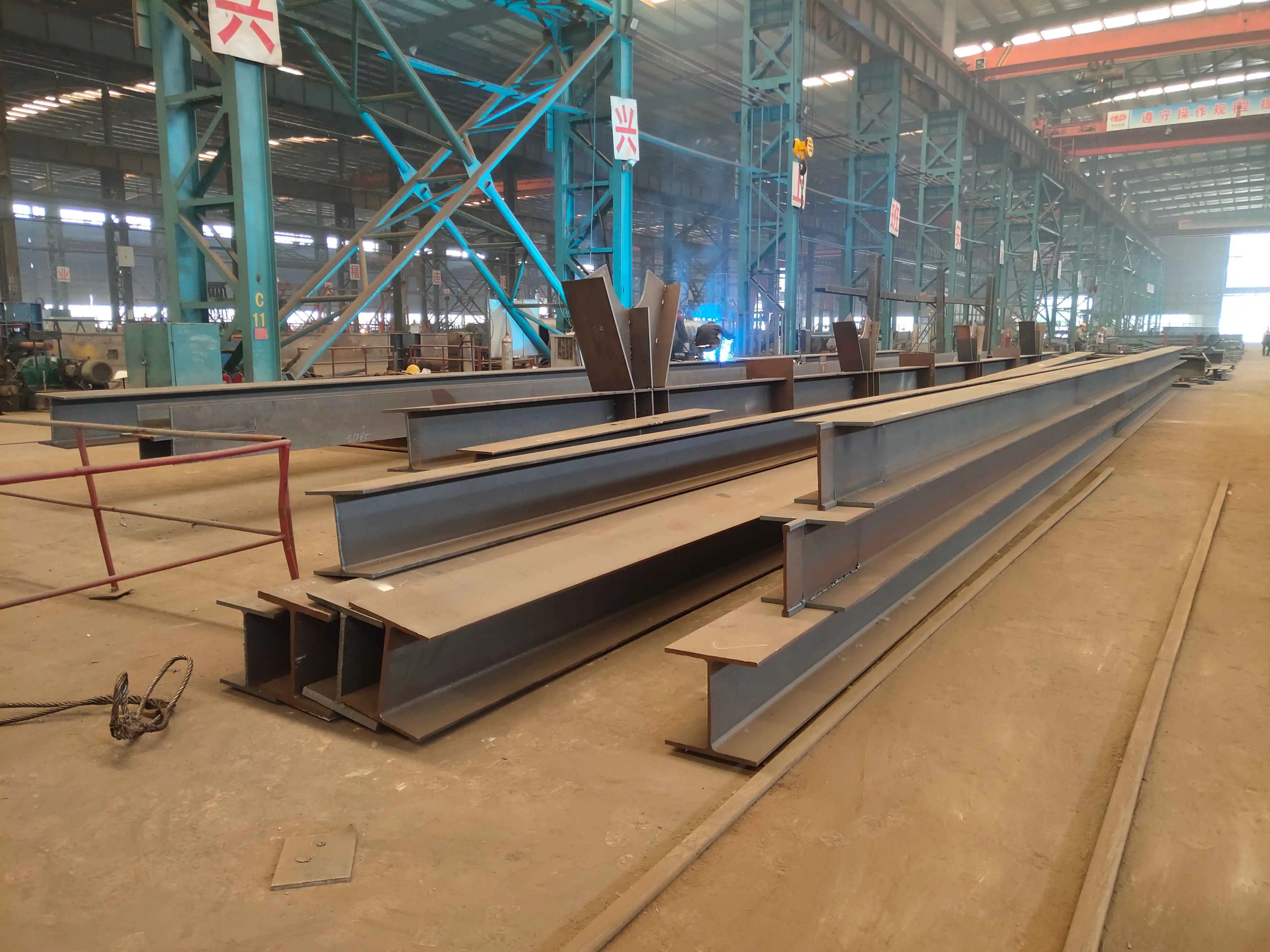

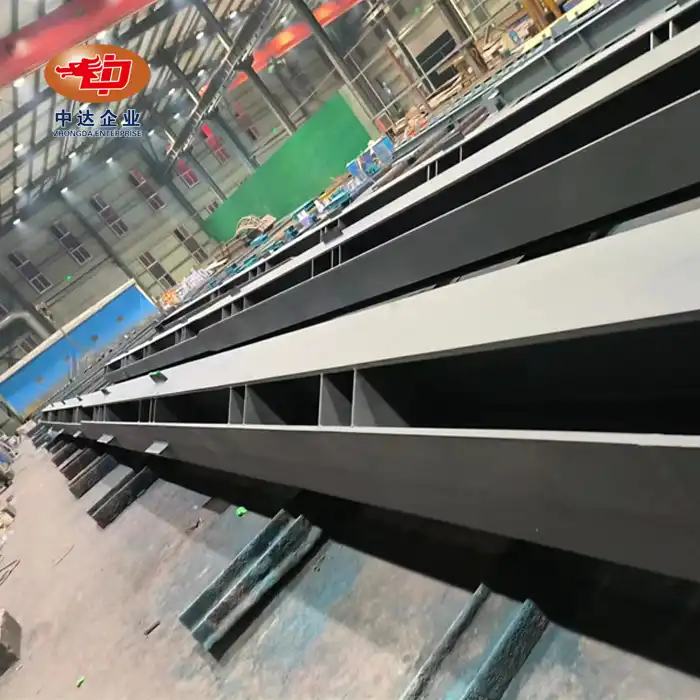

Our new building in the Shenyang Economic-Technological Development Zone is 120,000 square meters and has a yearly capacity of 60,000 tons. It uses cutting-edge BIM-driven prefabrication technology and a unique method of using weathering steel that can withstand temperatures as low as −60°C. These capabilities allow us to deliver specialized solutions for challenging environments, from Arctic bridge building in Russia to mining equipment structures in Australia.

Our promise to quality and reliability is shown by the relationships with China Railway, CSCEC, BMW, and other industry leaders we have built over time. When we cut ultra-thick plates, we keep ±0.2mm precision tolerances. This guarantees a perfect fit and fewer changes in the field. Whether your project needs standard structural grades or specialized weathering steel materials, our technical knowledge and global logistics capabilities support your success.

Conclusion

To evaluate structural steel materials, you need to do a deep study of technical specs, what the seller is able to do, and costs that affect the results of the project. Understanding steel grades, compliance requirements, and performance characteristics helps you make smart purchasing choices that are best for both short-term and long-term building and structural performance.

Good procurement methods focus on supplier dependability and quality assurance while balancing technical needs with economic goals. Because construction has become so complicated, it is important to work with suppliers who know what the industry needs and can always deliver high quality on time.

FAQs

What structural steel material grade is best for business building projects?

ASTM A992 is the best grade for commercial building because its chemistry makes it easy to weld and it has very strong properties. ASTM A36 is still a good choice for general structural uses that don't need a lot of strength. It is easy to weld and doesn't cost much.

How can I check that a structural steel source is certified?

Ask for copies of mill test certificates for certain material lots, quality management certificates like ISO 9001, and welding certificates like EN 1090. Third-party inspection records and customer references provide additional verification of supplier capabilities and quality performance.

What affects structural steel prices the most?

Raw material costs, steel grade specifications, order volume, processing requirements, and market supply conditions mainly decide pricing. The total cost of procurement is also affected by supply times, transportation costs, and value-added services such as fabrication or cutting.

Partner with Zhongda for Premium Structural Steel Material Solutions

Zhongda provides exceptional structural steel material quality backed by decades of manufacturing expertise and global project experience. Our wide range of skills, which include everything from working with raw materials to precision fabrication, makes sure that your project gets the best solutions suited to its exact needs.

Besides just supplying materials, we also offer value-added services like BIM-driven prefabrication, custom cutting with precise tolerances, and specialized anti-corrosion processes that make materials last longer in tough conditions. Our history of success with foreign projects shows that we can meet tight deadlines and high standards.

Ready to talk about what you need in terms of structural steel materials? Our technical experts are ready to meet with you one-on-one and come up with ways to make your projects more successful. To start the procurement process with a reputable structural steel material supplier dedicated to engineering excellence and global effect, email us at Ava@zd-steels.com.

References

American Institute of Steel Construction. "Steel Construction Manual, 15th Edition." AISC, 2017.

Chen, Wai-Fah, and Eric M. Lui. "Handbook of Structural Engineering, Second Edition." CRC Press, 2005.

Galambos, Theodore V., et al. "Structural Steel Design: LRFD Approach." Pearson Education, 2016.

Salmon, Charles G., and John E. Johnson. "Steel Structures: Design and Behavior." Harper & Row Publishers, 2009.

Segui, William T. "Steel Design, Sixth Edition." Cengage Learning, 2018.

Trahair, Nicholas S., et al. "Steel Member Design for Buildings." Australian Institute of Steel Construction, 2014.

(1)_副本_1760321095013.jpg)