Compared to common options, custom steel box girders make the structure more efficient by spreading the load more evenly, making better use of the material, and allowing for more design freedom. Their fully welded box design gives them better resistance to twisting and better strength-to-weight ratios. This makes them great for complex infrastructure projects and long-span bridges. Custom engineering makes it possible to exactly fit specific loading conditions, environmental factors, and project limitations. This leads to buildings that perform at their best while also minimizing material waste and construction time.

Understanding Steel Box Girders and Their Customization

Steel box girders are a basic but important step forward in structural engineering. Their cross-section looks like a box, which makes them very strong and useful in many different situations. As the basic support of today's infrastructure, these building blocks have given engineers the chance to make quick and long-lasting fixes for difficult projects in a range of fields.

Defining Steel Box Girder Construction

These girders are different from regular I-beams and other building options because of the fully welded box form. This setup makes a closed section that spreads the weight around the frame better. Single box designs are good for medium spans, but multi-cell setups are better for longer distances and bigger loads. By changing the cross-section along the length of the girder, tapered designs use material more efficiently by putting more material where stresses are strongest.

Choosing the right material is very important for how well customization works. The main material is high-strength Q345D steel, which has a yield strength greater than 345 MPa. Q420D steel is used to make important joints and links stronger. This planned placement of materials makes sure that the best work is done while also keeping an eye on costs.

Customization Advantages Over Standardized Solutions

The main advantages of customization can be seen when looking at the needs of a certain job. Variable cross-section shapes let beams be anywhere from 1.25 to 8 meters high, which works for a range of structural needs. With this kind of flexibility, engineers are able to keep the strength of a structure while making it up to 20% lighter. With the help of customization, projects can be scaled up to cover lengths of up to 420 meters.

Custom engineering also looks at natural factors like earthquakes, high winds, and changes in temperature. Engineers can add curved steel webs to keep projects light while maintaining strength, or they can change the thickness of walls to handle different types of weight for each project.

Comparing Steel Box Girders with Other Girder Types for Structural Efficiency

To understand structural economy, you need to look at how different kinds of girders hold up in different situations. This analysis shows why custom steel box girders often work better for tough building projects.

Steel Box Girders Versus Traditional Alternatives

Steel box girders offer major construction time savings when compared to concrete girders. With pre-fabrication, parts can be made somewhere else with lengths of 12 to 30 meters. This cuts the time needed to put everything together at the spot in half. This speed means that projects get done faster and labor is cheaper.

I-beams and truss girders are easier to make, but the sealed box section can better resist twisting. The box shape spreads out the weight more widely, which lowers stress in certain areas that could cause early failure. This better spread of the load makes it possible to have longer spans with less material, which directly makes the structure more efficient.

It is more difficult and expensive to use composite and prestressed girders because they need special building methods. Steel box girders work similarly by choosing the right materials and optimizing geometry. They also make the building and installation of structures easier.

Dynamic Load Performance and Environmental Resistance

When used in bridges or for industrial purposes, steel box girders work well when loads are constantly changing. The enclosed part can better withstand vibration and fatigue than open areas. This feature is especially useful in train bridges, walkways for people, and buildings that hold up machines that are moving.

Advanced anti-corrosion treatments, like specialized coats or double protection through galvanizing, can make something last more than 30 years. This lasts longer than many other materials, which greatly lowers costs over the entire duration.

The Fabrication and Construction Process of Customized Steel Box Girders

Modern ways of building make it possible to make exact, custom-fit parts for any structure. Using advanced technology to integrate makes sure that the quality is always the same while keeping the ability to change things for project-specific needs.

Advanced Manufacturing Technologies

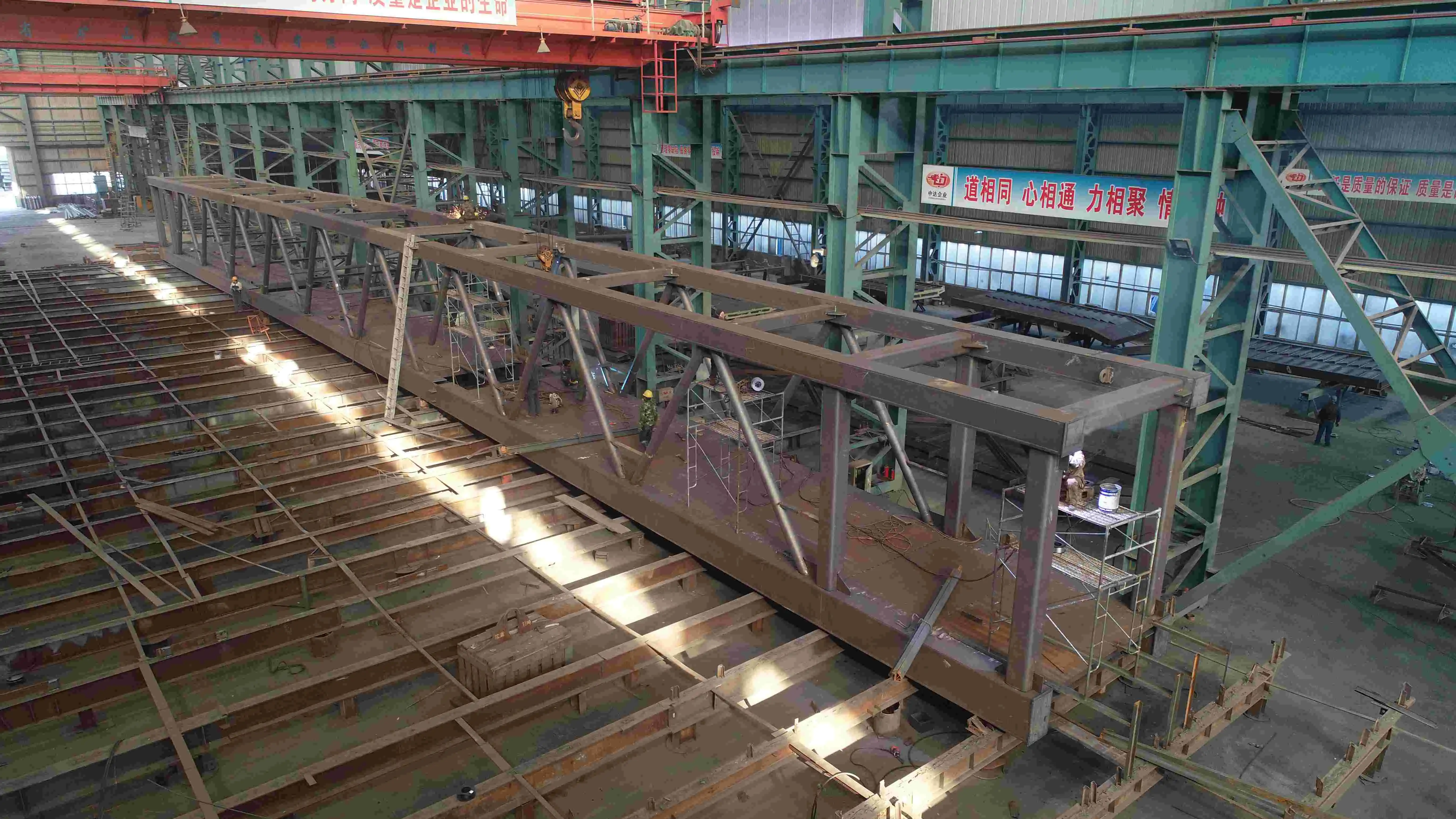

CNC ultra-thick plate cutting technology can cut plates with errors of only ±0.2 mm, which makes sure that the pieces fit together perfectly during assembly. This level of accuracy shortens the time needed for soldering and makes the structure better. Automated welding lines keep the quality of the welds the same during the whole production process, getting rid of the differences that come with doing things by hand.

Modular fabrication makes it possible to build complicated beams in sections that are easier to work with. This plan takes transportation issues into account while keeping the structure intact with well-planned splice links. Quality control systems keep an eye on every step of the production process to make sure they meet foreign standards like ISO 9001, EN 1090, and AWS.

Construction and Installation Strategies

Prefabrication has a big effect on both the time it takes to complete a job and the quality of the finished product. Making girders in a controlled workplace setting gets rid of delays caused by weather and makes sure that the working conditions are always the same. Transportation planning looks at the route limitations and girder dimensions and weight in order to make efficient transport plans.

On-site building methods keep the structure efficient by making sure the parts are lined up and connected correctly. While quality checks make sure that the work was done right, temporary braces and lifting gear place the steel box girders in the right spot. These methods make sure that the finished building works the way it was supposed to and lowers the risks involved in building it.

Procurement Insights for Customized Steel Box Girders

Procurement is only done right when people know what the market is like, what the project needs, and what the suppliers can do. Choosing the right suppliers strategically affects the results of a project. This makes the choice very important for getting the structure to work well.

Supplier Evaluation and Selection Criteria

Effective supplier evaluation looks at technical knowledge, production capacity, and quality systems. The number of tons that can be produced in a year, the size of the building, and how advanced the equipment is are all examples of production capacity indicators. Suppliers with a 60,000-ton yearly capacity show that they can work on the big infrastructure projects that are needed.

Quality management systems, welding qualifications, and standards that are specific to the business are all part of the certification process. ISO 9001/14001/45001 are examples of international certifications that show a consistent focus on quality, and EN 1090 and AWS certifications are examples that show a high level of knowledge about welding. These standards make sure that suppliers can get goods that meet the needs of projects all over the world.

Cost Optimization and Risk Management

Procurement plans find a balance between the cost, quality, and time that needs to be taken into account. Getting suppliers involved early in the planning process can help with value engineering, which makes the best use of materials and time when making parts. When planned projects are taken into account, bulk buying can lower the cost of each item and make sure there is enough stock on hand.

Looking at a supplier's financial stability, output capacity, and backup plans is part of risk mitigation. A variety of suppliers lowers the risk of dependency, and performance tracking makes sure that capability is always maintained. These methods keep projects on time and within price, even when unexpected things happen.

Maintenance Tips and Longevity of Customized Steel Box Girders

Long-term structural efficiency relies on planning and carrying out the right kind of maintenance. Custom designs can include things that make upkeep easier and increase the product's lifespan, which is the best way to get a return on investment.

Preventive Maintenance Strategies

Routine inspection plans find possible problems before they have an impact on how well the structure performs. Visual inspections look at the state of the coating, the strength of the connections, and any signs of trouble. When visual methods aren't enough, ultrasonic testing, magnetic particle inspection, and other advanced techniques can find flaws below the surface.

Corrosion protection care keeps the anti-corrosion systems that were used during fabrication in good shape. Double protection systems that use both galvanizing and specialty coatings protect the system twice and lengthen the time between maintenance sessions. As long as you clean often, you won't have anything on your surfaces that could damage the systems meant to protect them.

Design Features for Reduced Maintenance

Customization makes it possible to add features that make maintenance easier during the design process. Access provisions make sure that people who need to do repair or inspections can safely get to important parts of the system. Systems for drainage stop water from building up and speeding up rust, and smooth surfaces make it easier to clean and apply coatings.

The upkeep needs are greatly affected by the choice of material. Weathering steel choices form layers of oxide that protect the steel and lower the need to maintain the protection. If you use these materials in the right places, you can keep lifetime costs low and structural performance high.

Zhongda Steel Box Girder Solutions

Shenyang Zhongda Steel Structure Engineering Co., Ltd. focuses on providing custom structure solutions that make projects more efficient and dependable. Our all-encompassing method includes planning consultation, exact fabrication, logistics organization, and installation help to make sure that the project runs smoothly.

We have cutting-edge CNC technology for cutting, systems for automated welding, and strict quality control methods that make sure everything is made correctly. Our 120,000-square-meter plant can produce 60,000 tons a year, and we work on projects from building up the local area to huge projects with lots of countries involved. Our BIM-driven design integration makes project coordination easier and cuts down on building time by 20–30%.

Our ability to work on complex applications is shown by the notable successes of our projects. The 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge shows that we know how to build big bridges, and our work on projects in Russia, Australia, and Vietnam shows that we can adapt to different situations around the world.

Conclusion

Custom steel box girders offer better structural efficiency by using optimized design, advanced materials, and exact manufacture. Their fully welded design spreads the weight more evenly and resists twisting better than other options. Using strong materials, variable cross-sections, and modern building methods together makes it possible to lower weight while increasing span possibilities. The benefits of prefabrication include a big decrease in the time needed for building, and full anti-corrosion systems guarantee reliable service for decades. If you plan your maintenance and strategic buying, you will get the most out of these benefits, which will create value throughout the project lifecycle.

FAQs

What determines how much custom-made steel box girders cost?

The cost is based on the level of material, the size of the order, the difficulty of the fabrication, and the number of items ordered. Q345D and Q420D steels are examples of high-strength materials that cost a lot of money. Complex shapes add to the time needed to make the parts. Getting involved with suppliers early on in the planning process can help you find value engineering opportunities that make the best use of materials and lower costs.

How does making steel box girders unique help them hold more weight?

Wall thicknesses, internal stiffening, and custom sizes make load paths better for the needs of each job. Variable cross-sections put material where the stresses are strongest, and corrugated steel webs keep strength while lowering weight. This focused method can lower weight by 20% while keeping the load capacity the same or improving it.

How long does it usually take to send custom steel box girders?

It takes anywhere from a few weeks to a few months to deliver based on the complexity of the project, the size of the girder, and the number of orders. For normal jobs, pre-made parts that are 12 to 30 meters long usually take 6 to 12 weeks. Complex changes or big orders might take more time, so early planning and working with suppliers is important to keep on schedule.

Partner with Zhongda for Superior Steel Box Girder Solutions

Zhongda's custom structural solutions can help you get more done on your next infrastructure job. Our engineering team uses new manufacturing technology with decades of experience to make girders that exceed performance goals while lowering the cost and length of time needed for projects.

As a top maker of steel box girders, we offer a lot of different ways to customize your order. For example, you can choose cross-sections that are anywhere from 1.25m to 8m tall, spans that reach 420 meters, and special anti-corrosion treatments for places that are tough on materials. We can be counted on to deliver anywhere in the world because of our ISO-certified quality processes and experience with projects around the globe.

Are you ready to make your project's structure as efficient as possible? Get in touch with our professionals to talk about your needs and learn how personalized options can improve your project's success. For more information on product specs and project case studies, you can email us at Ava@zd-steels.com. Zhongda's proven skill should help make your project a success.

References

Chen, W.F. and Duan, L. "Bridge Engineering: Seismic Design." CRC Press, 2003.

Galambos, T.V. "Guide to Stability Design Criteria for Metal Structures." John Wiley & Sons, 1998.

Narayanan, R. "Steel Box Girder Bridges: Design and Construction." Applied Science Publishers, 1982.

Xanthakos, P.P. "Theory and Design of Bridges." John Wiley & Sons, 1994.

Wright, R.N. and Walker, W.H. "Criteria for the Deflection of Steel Bridges." American Institute of Steel Construction, 1971.

Zhou, F. "Web Crippling of Steel Girders under Concentrated Loading." Journal of Constructional Steel Research, 2005.

_副本_1754364944578.jpg)

(1)_副本_1760321095013.jpg)