Sustainability and Resource Conservation

Recyclability of Steel

One of the most significant environmental advantages of steel structures is the material's exceptional recyclability. Steel can be recycled indefinitely without losing its strength or quality, making it a truly sustainable building material. This characteristic significantly reduces the demand for raw materials and minimizes waste in the construction industry.

According to the World Steel Association, the recycling rate for steel from demolished buildings is as high as 98% for structural elements. This high recycling rate translates to substantial energy savings and reduced CO2 emissions compared to producing new steel from raw materials.

Reduced Material Waste

Steel structures are typically prefabricated off-site, allowing for precise measurements and minimal waste during the manufacturing process. This approach significantly reduces on-site material waste, which is a common issue with traditional construction methods. The controlled factory environment also enables better quality control and optimization of resources.

Studies have shown that steel construction can reduce on-site waste by up to 70% compared to traditional building methods. This reduction in waste not only benefits the environment but also leads to cost savings for construction projects.

Long-Term Durability

Steel structures are known for their exceptional durability and longevity. The strength and resilience of steel allow buildings to withstand harsh environmental conditions, natural disasters, and the test of time. This durability translates to fewer repairs, replacements, and renovations over the structure's lifetime, reducing the overall environmental impact.

With proper maintenance, steel structures can last for several decades, sometimes even centuries. This long lifespan reduces the need for frequent rebuilding and the associated environmental costs of demolition and new construction.

Energy Efficiency and Carbon Footprint Reduction

Improved Thermal Performance

Modern steel structures incorporate advanced insulation techniques and materials, resulting in superior thermal performance. This enhanced insulation helps maintain consistent indoor temperatures, reducing the energy required for heating and cooling. As a result, steel buildings can significantly lower their carbon footprint and operational costs.

Research indicates that well-designed steel buildings can achieve energy savings of up to 50% compared to conventional structures. This reduction in energy consumption directly translates to lower greenhouse gas emissions over the building's lifetime.

Integration of Renewable Energy Systems

Steel structures provide an excellent framework for integrating renewable energy systems such as solar panels and wind turbines. The strength and versatility of steel allow for easy installation of these systems, promoting the use of clean energy and further reducing the building's environmental impact.

For instance, large-scale steel-framed warehouses and industrial buildings offer ideal surfaces for extensive solar panel installations, potentially generating enough energy to power the entire facility and even feed excess electricity back into the grid.

Lightweight Construction

Steel's high strength-to-weight ratio allows for lighter construction compared to traditional materials like concrete. This lightweight nature reduces the overall mass of the building, leading to smaller foundations and less material usage. Consequently, the carbon footprint associated with material production and transportation is significantly lowered.

Studies have shown that steel-framed buildings can be up to 50% lighter than equivalent concrete structures, resulting in substantial reductions in foundation size and associated carbon emissions.

Environmental Impact During Construction and Demolition

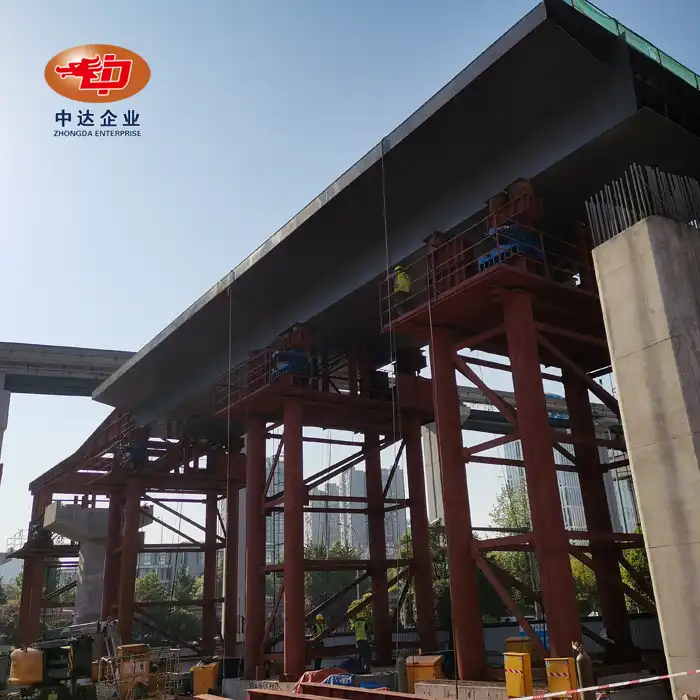

Reduced Construction Time

Steel structures can be assembled much faster than traditional building methods, leading to shorter construction periods. This speed translates to reduced on-site energy consumption, fewer vehicle emissions from construction equipment, and minimal disruption to the surrounding environment.

According to industry reports, steel construction can reduce overall project timelines by up to 40% compared to conventional methods. This efficiency not only benefits the environment but also leads to significant cost savings for project stakeholders.

Lower Noise and Air Pollution

The prefabrication of steel components off-site results in quieter and cleaner construction sites for steel structures. This approach minimizes dust, noise, and air pollution typically associated with on-site construction activities, creating a more environmentally friendly building process and reducing the impact on neighboring communities.

Studies have shown that prefabricated steel construction can reduce on-site noise levels by up to 50% and dust emissions by up to 90% compared to traditional construction methods.

Easier Demolition and Material Recovery

When a steel structure reaches the end of its life cycle, the demolition process is typically cleaner and more efficient than that of traditional buildings. Steel components can be easily separated and recycled, minimizing landfill waste and promoting a circular economy in the construction industry.

Research indicates that up to 99% of structural steel can be recovered and recycled during demolition, significantly reducing the environmental impact of building removal and supporting sustainable construction practices.

Conclusion

The environmental benefits of using steel structures are numerous and significant. From sustainability and resource conservation to energy efficiency and reduced environmental impact during construction and demolition, steel emerges as a superior choice for eco-conscious building projects. As global leaders in steel solutions, Shenyang Zhongda Steel Structure Co., Ltd. is committed to driving innovation in sustainable construction, providing cutting-edge steel structures that not only meet the highest quality standards but also contribute to a greener, more sustainable future for our planet.

FAQs

1. How does steel compare to other building materials in terms of environmental impact?

Steel is highly recyclable and energy-efficient, often outperforming traditional materials like concrete in terms of sustainability and carbon footprint reduction.

2. Can steel structures be energy-efficient?

Yes, modern steel structures incorporate advanced insulation techniques and can easily integrate renewable energy systems, leading to significant energy savings.

3. What is the lifespan of a typical steel structure?

With proper maintenance, steel structures can last for several decades, sometimes even centuries, reducing the need for frequent rebuilding.

Sustainable Steel Solutions for a Greener Future | Zhongda Steel

At Shenyang Zhongda Steel Structure Co., Ltd., we're committed to providing environmentally friendly steel solutions for global projects. As a leading steel structure manufacturer and supplier, we combine innovation with sustainability to deliver high-quality, eco-conscious products. For expert guidance on your next green building project, contact us at Ava@zd-steels.com.

References

1. World Steel Association. (2021). Steel's Contribution to a Low Carbon Future.

2. Green Building Council. (2020). Environmental Benefits of Steel in Construction.

3. Journal of Sustainable Architecture and Civil Engineering. (2019). Comparative Analysis of Steel and Concrete Structures' Environmental Impact.

4. International Journal of Construction Management. (2018). Energy Efficiency in Steel-Framed Buildings: A Comprehensive Review.

5. Environmental Science & Technology. (2022). Life Cycle Assessment of Steel Structures in Green Building Design.

6. Structural Engineering International. (2021). Innovations in Sustainable Steel Construction: Current Trends and Future Prospects.

_副本_1753431734739.webp)