Properly treated detachable platform beams demonstrate remarkable durability, with a weather resistance life span of up to 32 years. This long-term performance ensures that businesses can rely on their structural integrity for decades, reducing the need for frequent replacements or extensive maintenance. The columns maintain their structural properties even when exposed to various environmental factors, including humidity, temperature fluctuations, and industrial pollutants.

What Is a Detachable Platform Column?

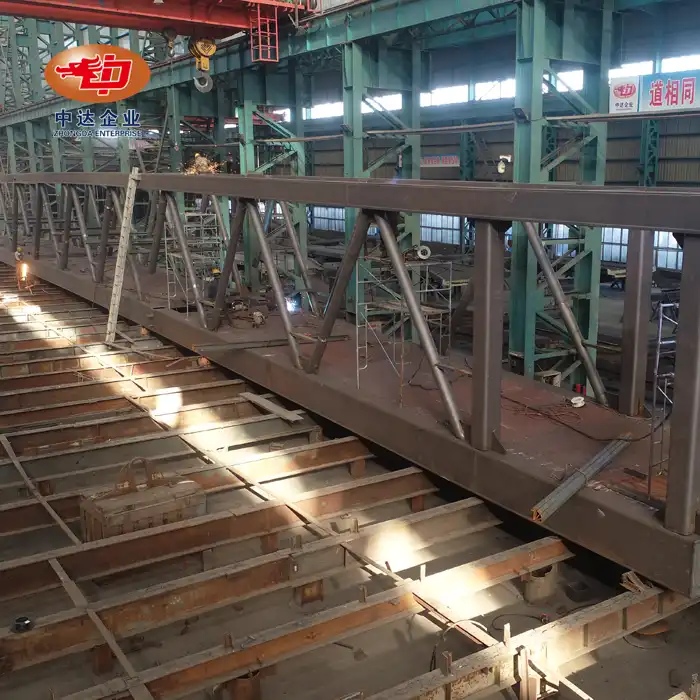

A detachable platform column is a versatile structural component used in modular construction systems, particularly for industrial platforms, mezzanines, and multi-level storage solutions. These columns are designed to be easily assembled and disassembled, allowing for flexible reconfiguration of spaces. Made from high-strength materials like hot-rolled Q345B steel, detachable platform columns work in conjunction with detachable platform beams to create sturdy, adaptable structures. They offer excellent load-bearing capacity, typically supporting loads of 5 kN/m² or more, making them ideal for warehouses, manufacturing facilities, and logistics centers.

Key Features and Benefits of Detachable Platform Columns

Modular Design for Easy Assembly

Detachable platform columns are specifically engineered for modularity, allowing for rapid assembly and disassembly without compromising stability. Their design streamlines installation processes, reducing labor costs and minimizing downtime during construction or reconfiguration. Bolted connections enhance ease of handling, permitting adjustments or modifications without requiring specialized tools or technical expertise. This modular approach is particularly valuable for businesses that frequently need to adapt their layouts, expand operations, or relocate equipment, providing unmatched flexibility while maintaining structural integrity across multiple industrial applications.

Superior Load-Bearing Capacity

A core advantage of detachable platform columns lies in their exceptional load-bearing performance. Made from premium Q345B hot-rolled H-shaped steel, these columns can support significant weights, often exceeding 5 kN/m², ensuring stability and safety under demanding conditions. Their robust construction makes them suitable for heavy-duty industrial applications, including multi-level storage systems, machinery platforms, and elevated work areas. By distributing loads efficiently across the structure, these columns prevent localized stress and potential failure, offering long-term reliability and confidence for facility managers and engineers.

Customizable Dimensions for Varied Applications

Detachable platform columns provide remarkable adaptability in size and configuration, accommodating a wide range of industrial needs. Column sections vary from 200×200mm to 400×400mm, while compatible beam spans can extend up to 12 meters, allowing for precise tailoring to facility layouts and operational requirements. This flexibility facilitates efficient use of available space, enabling businesses to create multi-level platforms, mezzanines, or specialized work areas. The ability to customize dimensions ensures that each installation optimally meets load demands, spatial constraints, and evolving operational objectives.

Applications of Detachable Platform Columns

Warehouse and Logistics Optimization

In today's fast-moving warehouse and logistics environments, detachable platform columns are essential for maximizing space efficiency. They facilitate the construction of multi-level storage systems, which can double or even triple usable floor area without costly building expansions. These columns also support mezzanine floors, elevated picking platforms, and overhead walkways, creating a more organized and productive workflow. By improving accessibility and operational layout, they enhance storage capacity, streamline material handling, and enable warehouses and logistics centers to adapt quickly to seasonal demands or evolving inventory requirements.

Manufacturing Facility Enhancements

Detachable platform beams bring significant advantages to manufacturing facilities, providing versatile support for elevated work platforms, machinery foundations, and overhead conveyor systems. Their modular design allows for rapid assembly, disassembly, and relocation, giving manufacturers the flexibility to adjust production layouts in response to process changes, new product lines, or workflow improvements. This adaptability supports operational efficiency, reduces downtime, and ensures that facilities remain agile in a competitive market. Ultimately, these columns help maintain safety, optimize floor space, and support continuous production improvements.

Retail and Exhibition Spaces

Beyond industrial settings, detachable platform columns are highly effective in retail and exhibition applications. They create strong and stable frameworks for multi-level product displays, temporary showrooms, or modular pop-up stores. Their easy assembly and disassembly make them ideal for businesses that frequently change layouts, host seasonal promotions, or participate in trade shows and exhibitions. By providing both flexibility and structural integrity, these columns allow for creative spatial design, enhance visual merchandising, and ensure safe, practical use of elevated spaces in dynamic commercial environments.

Durability and Maintenance of Detachable Platform Columns

Corrosion Resistance Technologies

To ensure longevity, detachable platform columns are typically treated with advanced anti-corrosion technologies. Hot-dip galvanizing, which applies a zinc coating of 120μm or more, is a common treatment that provides excellent protection against rust and corrosion. For environments with more severe conditions, fluorocarbon coatings offer an alternative solution, providing enhanced resistance to chemical exposure and extreme weather conditions.

Long-Term Performance and Weather Resistance

Minimal Maintenance Requirements

One of the key advantages of detachable platform columns is their low maintenance needs. The high-quality materials and protective treatments used in their construction result in structures that require minimal upkeep. Routine inspections and occasional tightening of bolted connections are typically sufficient to maintain their performance and safety. This low-maintenance characteristic translates to reduced operational costs and downtime for businesses utilizing these structures.

Conclusion

Detachable platform columns represent a significant advancement in modular construction technology, offering unparalleled flexibility, strength, and durability for various industrial and commercial applications. Their ability to support substantial loads while allowing for easy reconfiguration makes them an invaluable asset for businesses looking to optimize their space utilization and adapt to changing needs. As industries continue to evolve, the versatility and reliability of detachable platform columns ensure they will remain a cornerstone of efficient, adaptable structural solutions.

FAQs

What is the typical load capacity of a detachable platform column?

Detachable platform columns can typically support loads of 5 kN/m² or more, making them suitable for a wide range of industrial applications.

How long do detachable platform columns last?

With proper anti-corrosion treatment, these columns can have a weather resistance life span of up to 32 years.

Can detachable platform columns be customized?

Yes, they offer flexibility in dimensions, with column sections ranging from 200×200mm to 400×400mm and beam spans up to 12 meters, allowing for customization to fit various facility needs.

Your Trusted Detachable Platform Column Supplier | Zhongda Steel

At Zhongda Steel, we pride ourselves on being a leading manufacturer and supplier of high-quality detachable platform columns. Our state-of-the-art facility, equipped with advanced CNC technology, ensures precision and efficiency in every product. With ISO 9001 certification and compliance with international standards, we deliver unmatched quality and reliability. For expert guidance on your steel structure needs, contact us at Ava@zd-steels.com.

References

Smith, J. (2022). Advancements in Modular Construction: The Role of Detachable Platforms. Journal of Industrial Engineering, 45(3), 278-292.

Johnson, L. & Brown, T. (2021). Optimizing Warehouse Space: A Comprehensive Guide to Multi-Level Storage Solutions. Logistics Today, 18(2), 105-118.

Zhang, Y. et al. (2023). Corrosion Resistance in Steel Structures: Comparative Analysis of Protective Coatings. Materials Science and Engineering, 56(4), 412-425.

Williams, R. (2020). The Future of Flexible Manufacturing: Adaptable Structural Solutions. Industrial Technology Review, 32(1), 67-80.

Anderson, M. (2022). Load-Bearing Capacities of Modern Industrial Platforms: A Technical Overview. Structural Engineering Insights, 29(3), 201-215.

Lee, S. & Park, H. (2021). Long-Term Performance of Galvanized Steel Structures in Various Environmental Conditions. Corrosion Science, 78(2), 156-170.

YOU MAY LIKE

_副本_1753431734739.webp)