Design Standards for Weathering Steel Box Girder Bridges

Design standards for weathering steel box girder bridges encompass a comprehensive set of guidelines that ensure structural integrity, durability, and efficiency. These standards address material specifications, load-bearing capacities, corrosion resistance, and construction methodologies. By adhering to these rigorous standards, engineers can create bridges that withstand harsh environmental conditions, reduce maintenance costs, and provide long-lasting infrastructure solutions. Shenyang Zhongda Steel Structure Engineering Co., Ltd., a leading weathering steel box girder manufacturer, consistently exceeds these standards, offering superior products for modern bridge construction projects worldwide.

Material Specifications and Structural Design

Steel Grade Selection

Choosing the right steel grade is crucial for weathering steel box girder bridges. High-strength low-alloy (HSLA) steels, such as ASTM A709 Grade 50W or equivalent, are commonly specified. These steels offer excellent corrosion resistance and mechanical properties, with yield strengths typically ranging from 345 MPa to 485 MPa. At Zhongda Steel, we use Q345D as the main material (≥345MPa) and Q420D for joints, ensuring optimal strength and durability.

Cross-Section Optimization

The cross-section of weathering steel box girders plays a vital role in their performance. Design standards recommend variable cross-sections to optimize weight distribution and load-bearing capacity. Our engineering team at Zhongda Steel offers customizable cross-sections ranging from 1.25 to 8 meters in height, allowing for a 20% weight reduction compared to traditional designs while maintaining structural integrity for spans up to 420 meters.

Fatigue Resistance

Fatigue resistance is a critical factor in bridge design, especially for structures subject to repetitive loading. Design standards specify minimum fatigue life requirements and detail categories for various welded connections. Our weathering steel box girders undergo rigorous fatigue testing to ensure they meet or exceed these standards, providing long-term durability and safety.

Corrosion Protection and Maintenance

Protective Patina Formation

Weathering steel's inherent ability to develop a protective patina is one of its most significant advantages in bridge construction. This naturally forming oxide layer shields the steel from further corrosion when environmental conditions are properly managed. Design standards provide guidance on wet-dry exposure cycles, air circulation, and surface preparation to optimize patina development. Zhongda Steel carefully engineers box girders to encourage uniform and effective patina formation, reducing the need for coatings or paints while ensuring long-term durability and resistance to atmospheric corrosion.

Drainage and Moisture Control

Proper management of water and moisture is critical for extending the lifespan of weathering steel structures. Design standards define slope requirements for horizontal surfaces and recommend drainage strategies to prevent water accumulation within box girders. Zhongda Steel integrates advanced drainage channels, vents, and airflow paths into our designs, ensuring that water does not pool and humidity is minimized. These features protect structural components from rust, limit corrosion risks, and maintain the integrity and load-bearing capacity of girders under varying environmental conditions over decades.

Inspection and Maintenance Protocols

Routine inspections and maintenance are essential to preserve the performance and safety of weathering steel box girder bridges. Design standards provide clear guidance on inspection intervals, procedures, and critical areas to monitor, such as welds, joints, and internal cavities. Zhongda Steel's girders are designed with inspection accessibility in mind, incorporating internal access points and visual indicators of structural condition. Regular monitoring and timely maintenance allow these box girders to achieve a service life of 33 years or more, ensuring long-term reliability and safety in demanding infrastructure applications.

Construction and Assembly Techniques

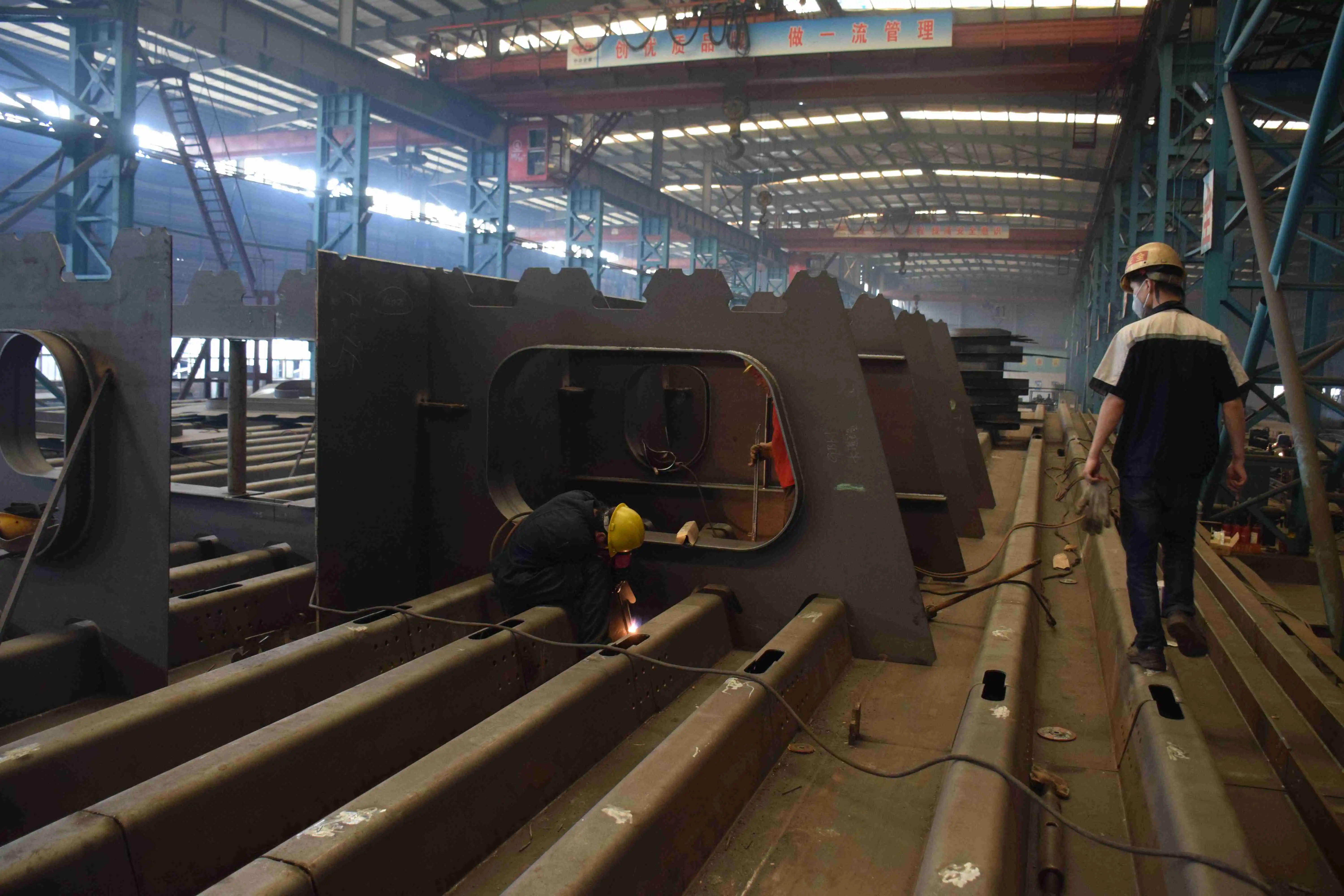

Prefabrication Methods

Modern bridge construction increasingly depends on prefabrication to enhance efficiency, precision, and overall project quality. Zhongda Steel adheres to rigorous design standards that dictate the fabrication of weathering steel box girder segments, including precise welding techniques, dimensional tolerances, and comprehensive quality control measures. Our advanced manufacturing facilities are capable of producing prefabricated segments ranging from 12 to 30 meters, enabling rapid on-site assembly. This approach minimizes construction time by up to 50%, reduces labor costs, and mitigates risks associated with adverse weather conditions or complex site logistics.

On-Site Assembly Procedures

Accurate on-site assembly is crucial to ensuring the structural integrity and longevity of weathering steel box girders. Detailed design standards outline alignment, joining, and sealing procedures for each segment. Zhongda Steel's expert teams provide hands-on support during installation, supervising every step to guarantee correct placement and secure connections. The integration of prefabricated segments is carefully managed to prevent misalignment, structural stress, or joint failures, ensuring that each bridge performs safely and efficiently under dynamic loads and environmental conditions.

Quality Control and Testing

Maintaining the highest quality standards throughout bridge construction is essential for safety and durability. Zhongda Steel implements rigorous quality control procedures, including non-destructive testing of welds, dimensional inspections, and load-bearing verifications. Our state-of-the-art techniques, such as ultrasonic testing and magnetic particle inspection, detect potential defects and confirm material integrity. By adhering to these strict protocols, each box girder meets international standards for performance and reliability, ensuring long-term structural safety and resilience for bridges exposed to heavy traffic, environmental stresses, and extreme climatic conditions.

Conclusion

Adhering to design standards for weathering steel box girder bridges is crucial for creating safe, durable, and efficient infrastructure. These standards encompass material selection, structural design, corrosion protection, and construction techniques. By partnering with Shenyang Zhongda Steel Structure Engineering Co., Ltd., a leading weathering steel box girder supplier, you ensure that your bridge projects not only meet but exceed these rigorous standards. Our commitment to quality, innovation, and customer satisfaction makes us the ideal choice for your infrastructure needs.

FAQs

What is the typical lifespan of a weathering steel box girder bridge?

With proper design and maintenance, weathering steel box girder bridges can last 75-100 years.

How does weathering steel compare to traditional painted steel in terms of maintenance?

Weathering steel requires significantly less maintenance as it doesn't need repainting, reducing long-term costs.

Can weathering steel box girders be used in marine environments?

While suitable for many environments, weathering steel may require additional protection in highly corrosive marine settings.

Choose Zhongda Steel for Your Weathering Steel Box Girder Needs

As a premier weathering steel box girder manufacturer, Zhongda Steel offers unparalleled expertise in bridge construction solutions. Our state-of-the-art facility, with a 60,000-ton annual capacity, ensures timely delivery of high-quality products. From Arctic bridges to industrial hubs, our global project portfolio demonstrates our commitment to excellence. Experience the Zhongda difference in your next infrastructure project. Contact us at Ava@zd-steels.com for expert consultation and superior weathering steel box girder solutions.

References

American Association of State Highway and Transportation Officials. (2020). AASHTO LRFD Bridge Design Specifications, 9th Edition.

Tamakoshi, T., et al. (2018). "Design Standards for Steel Box Girder Bridges Using Weathering Steel." Journal of Bridge Engineering, 23(5).

European Committee for Standardization. (2019). Eurocode 3: Design of steel structures - Part 2: Steel Bridges.

Kihira, H., & Kimura, M. (2017). "Weathering Steel Bridges: Design, Fabrication, and Maintenance." CRC Press.

Federal Highway Administration. (2021). "Steel Bridge Design Handbook: Weathering Steel."

Japan Society of Civil Engineers. (2019). "Standard Specifications for Steel and Composite Structures: Bridges."

YOU MAY LIKE