The Science Behind Highway Sound Barrier Walls

Sound Wave Absorption and Reflection

Highway sound barrier walls employ a dual approach to combat noise pollution. The perforated outer layer, typically made of 2mm galvanized steel with a 23-30% perforation rate, allows sound waves to partially penetrate the barrier. Once inside, the high-density glass wool core, with its intricate network of fibers, absorbs a significant portion of the sound energy. This absorption process converts sound waves into heat through friction, effectively reducing the overall noise level.

Simultaneously, the solid portions of the outer layer reflect incoming sound waves back towards the source. This reflection helps to scatter the noise, further diminishing its intensity before it reaches nearby residential areas. The combination of absorption and reflection creates a powerful noise reduction system that can achieve a Noise Reduction Coefficient (NRC) of up to 0.81, as seen in Zhongda Steel's advanced barrier designs.

Diffraction and Sound Path Alteration

Another crucial aspect of highway sound barrier performance is diffraction. As sound waves encounter the top edge of the barrier, they bend or diffract around it. This phenomenon creates a "shadow zone" behind the barrier where noise levels are significantly reduced. The effectiveness of diffraction increases with the barrier's height and proximity to the noise source.

To enhance this effect, some barrier designs, like Zhongda Steel's arc-top barriers for rail transit applications, incorporate specialized shapes at the top edge. These shapes help to further scatter and diffuse sound waves, minimizing the "spill-over" effect and extending the quiet zone behind the barrier.

Material Innovation and Performance

The choice of materials plays a crucial role in the effectiveness of highway sound barriers. Modern barriers, such as those produced by Zhongda Steel, utilize composite structures that combine the strength and durability of steel with the sound-absorbing properties of materials like glass wool. This innovative approach results in barriers that are not only highly effective at noise reduction but also resistant to environmental factors.

For instance, Zhongda Steel's barriers feature a UV-resistant coating that can withstand 2000 hours of exposure without fading, ensuring long-lasting performance and aesthetics. Additionally, the use of high-quality galvanized steel provides excellent corrosion resistance, making these barriers suitable for a wide range of climatic conditions.

Design Considerations for Maximum Noise Reduction

Height and Length Optimization

The effectiveness of a highway sound barrier is closely tied to its dimensions. Generally, taller barriers provide better noise reduction, as they create a larger shadow zone and intercept more sound waves. However, practical considerations such as cost, aesthetics, and structural integrity often limit the maximum height of barriers.

To achieve optimal noise reduction, engineers carefully calculate the required barrier height based on factors such as the distance between the noise source and receiver, ground topography, and desired noise reduction levels. Zhongda Steel's modular design, offering sizes from 2 to 6 meters, allows for precise height adjustments to meet specific project requirements.

The length of the barrier is equally important. To prevent sound from flanking around the ends of the barrier, it should extend well beyond the area to be protected. This often results in barriers that run continuously for several kilometers along busy highways.

Barrier Placement and Orientation

The positioning of sound barriers relative to the noise source and the areas to be protected significantly impacts their effectiveness. Ideally, barriers should be placed as close to the noise source (i.e., the highway) as possible. This maximizes the path difference between the direct sound and the sound traveling over the barrier, enhancing the noise reduction effect.

In some cases, double barriers – one on each side of the highway – may be employed to further reduce noise levels and prevent sound reflections between opposing traffic lanes. The orientation of the barrier can also be adjusted to optimize its performance. Slight tilts or curves in the barrier design can help to reflect sound upwards, away from sensitive areas.

Surface Treatments and Aesthetics

While the primary function of highway sound barriers is noise reduction, their visual impact on the surrounding landscape cannot be overlooked. Modern barrier designs, like those offered by Zhongda Steel, incorporate various surface treatments and aesthetic considerations to blend with or enhance the local environment.

Perforations in the outer steel layer not only contribute to sound absorption but also create visually interesting patterns. Zhongda Steel offers over 200 color options based on the RAL color chart, allowing barriers to complement their surroundings or make bold design statements. Some barriers even incorporate vegetation or artistic elements, transforming them from mere functional structures into aesthetic assets for communities.

Installation and Maintenance of Highway Sound Barriers

Efficient Installation Processes

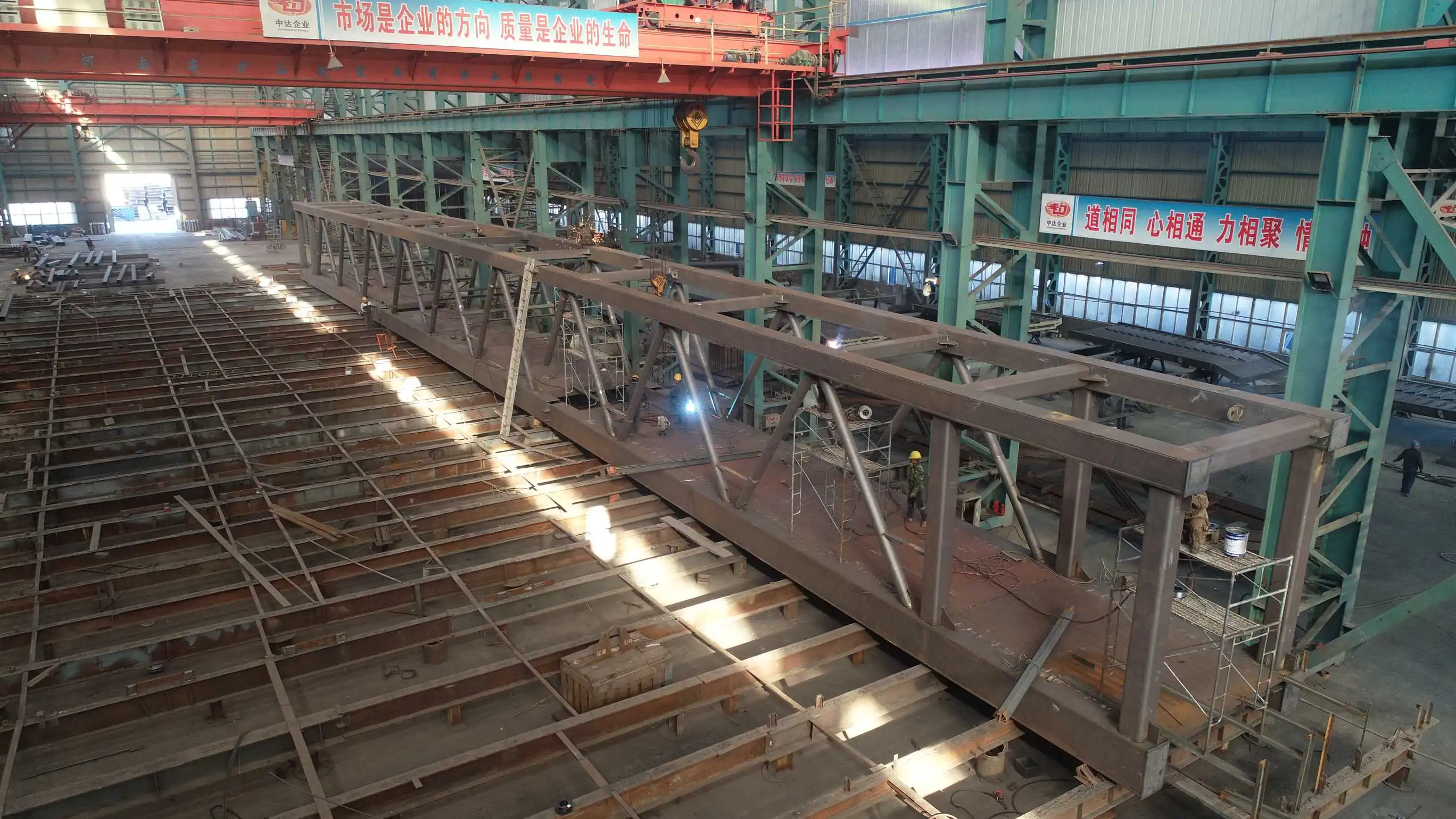

The installation of highway sound barriers is a critical phase that requires careful planning and execution. Zhongda Steel's modular design significantly streamlines this process, allowing for rapid and efficient installation. The prefabricated panels, ranging from 2 to 6 meters in length, can be quickly assembled on-site, minimizing traffic disruptions and construction time.

For highway applications, Zhongda Steel employs H-shaped columns combined with concrete foundations. This robust support system ensures the barriers can withstand wind pressures of up to 1.2kN/㎡, providing long-term stability and safety. The modular nature of the system also allows for easy replacement or expansion of sections as needed, providing flexibility for future highway modifications.

Long-term Durability and Weather Resistance

Highway sound barriers are exposed to harsh environmental conditions, including UV radiation, temperature fluctuations, and varying weather patterns. To ensure long-lasting performance, Zhongda Steel incorporates several durability-enhancing features into their barrier designs.

The galvanized steel outer layer provides excellent corrosion resistance, while the UV-resistant coating maintains the barrier's appearance and integrity for years. These barriers have undergone rigorous testing, including SGS 2000-hour UV resistance certification, demonstrating their ability to withstand prolonged exposure to sunlight without degradation.

For environments with particularly challenging conditions, Zhongda Steel offers weathering steel options. This specialized steel forms a protective patina over time, further enhancing the barrier's resistance to corrosion and reducing long-term maintenance requirements.

Maintenance and Performance Monitoring

While highway sound barriers are designed for low maintenance, regular inspections and upkeep are essential to ensure optimal performance throughout their lifespan. Periodic checks should be conducted to identify any damage, such as cracks, loose panels, or graffiti, which could compromise the barrier's effectiveness.

Zhongda Steel's barriers are designed with ease of maintenance in mind. The modular construction allows for the quick replacement of individual panels if necessary, minimizing downtime and repair costs. Additionally, the smooth, durable surface of the barriers facilitates easy cleaning and graffiti removal, helping to maintain their aesthetic appeal.

To ensure ongoing effectiveness, some highway authorities implement noise monitoring programs. These involve regular acoustic measurements to verify that the barriers continue to meet the required noise reduction levels. Such data can inform future barrier designs and help prioritize areas for barrier installation or upgrades.

Conclusion

Highway sound barrier walls have revolutionized noise control along busy roadways, offering a powerful solution to combat traffic noise pollution. Through innovative design, advanced materials, and strategic placement, these barriers can dramatically reduce noise levels, often by 25dB(A) or more. As urban areas continue to expand and traffic volumes increase, the importance of effective noise mitigation solutions cannot be overstated. With ongoing advancements in materials and design, highway sound barriers will continue to play a crucial role in enhancing quality of life for communities near busy roadways.

Contact Us

For state-of-the-art highway sound barrier solutions, turn to Zhongda Steel. Our innovative composite barriers offer superior noise reduction, durability, and customization options. Experience the benefits of our advanced outdoor sound barriers, backed by rigorous certifications and a proven track record of successful projects worldwide. Contact us at Ava@zd-steels.com to learn how we can help make your highways quieter and communities more livable.