It is important to make sure that a steel structure stadium maker has the right technical skills, is environmentally friendly, and has a history of building great sports facilities when choosing one. Today, when you buy things for a project, you need to find a mix between great building and environmental duty so that your project meets both efficiency and sustainability goals. The key is to find makers who use cutting-edge building methods, high approval standards, and show they know how to build big stadiums.

Defining Your Decision Scenario: Why Selecting the Right Manufacturer Matters

Choosing the right steel stadium maker comes with a lot of problems that go beyond the normal way of getting building materials. Because they are very noticeable and have to be safe, comfortable, and suitable for thousands of onlookers, sports infrastructure projects need to be exactly right.

Technical Complexity and Performance Standards

For steel structure arenas to be built, there needs to be a factory that can make lengths of over 300 meters without needing extra support. These buildings have to survive very harsh weather, like wind speeds of up to 200 km/h and seismic forces in areas where earthquakes are likely to happen. For project approval and long-term safety guarantee, the manufacturer's ability to provide thorough engineering calculations, finite element analysis, and extensive structure paperwork becomes crucial.

Sustainability Commitments and Environmental Impact

For modern stadium projects to protect the environment, they need to work with companies that have a history of eco-friendly practices. Because steel can be recycled, it has natural benefits, but the process of making steel must use production methods that are efficient so that the carbon footprint is low. Manufacturers show that they are committed to long-lasting building methods by using environmentally friendly finishing systems, energy-saving ways of making things, and waste-reduction programs.

Project Timeline Pressures and Delivery Reliability

Because of sports events, steel structure stadium building often has strict schedules, which makes it very important for manufacturers to be reliable. Delays in steel supply can push back the whole job, which can put event dates at risk and cause huge fines. The manufacturer's history of making tight dates without having to lower quality is an important factor in this decision.

Establishing Core Metrics for Evaluating Steel Stadium Manufacturers

A broad assessment system that looks at many different areas of performance is needed to pick the right maker. This method makes sure that buying teams think about all the right things and stay neutral when they make decisions.

Quality Assurance and Certification Standards

Strong quality control methods and industry approvals are the start of excellent manufacturing. ISO 9001 approval shows that you are committed to making sure that quality processes are always the same. At the same time, EN 1090 and AISC compliance makes sure that you follow international standards for structural steel. Through the use of specialized covering technologies, fire protection powers must meet REI 120 standards for public safety. Hot-dip galvanizing that follows the ISO 1461 standards protects against corrosion while providing long-lasting strength and lowering the need for upkeep.

Manufacturing Capabilities and Technology Integration

Complex structure parts can be made with great accuracy at advanced factories that have 100-ton bridge cranes and precision cutting tools. BIM-driven prefabrication makes it easier to coordinate manufacturing and cut down on the time it takes to put things together on-site. The manufacturer's skill in ultra-thick plate cutting with tolerances of ±0.2mm shows how exact modern steel structure stadium building needs to be.

Sustainability Credentials and Environmental Responsibility

Manufacturers are being chosen more and more based on environmental factors. To do this, buying teams look at efforts to lower carbon footprints and ways materials are sourced. Using steel that is 90% reusable and setting up systems for collecting rainwater are both ways for manufacturers to follow Green Public Procurement guidelines. ISO 14001 environmental management certification ensures that the production process has a consistent reduced impact on the environment.

Weighting Metrics and Analyzing Manufacturer Options

When you make difficult buying choices, you need to be aware of the trade-offs that come with having a lot of different goals during the review of manufacturers. This method of analysis gives buying teams the information they need to make smart decisions that improve all aspects of a project, including technical, financial, and environmental.

Developing a Balanced Scoring Framework

Professional buying teams use weighted score methods that show what is important for each job. Technical skills, like span capabilities, load rates, and accurate standards, usually make up 40% of the evaluation criteria. About 30% of the decision is based on cost, which includes the price, the cost over the lifetime, and the cost of upkeep. Sustainability measures make up 20% of the total score, which shows how important environmental rules for public buying have become. The other 10% deals with how reliable the delivery is and how well the project is managed, knowing that sticking to the building plan is very important.

Risk Assessment and Mitigation Strategies

A thorough manufacturer's evaluation includes a deep look at risks related to the company's finances, production capacity, and supply chain robustness. Factory checks give us useful information about how goods are made, how quality is checked, and how production can be scaled up. Before making their final choice, buying teams use sample component reviews to check on material features, welding quality, and surface finishing standards.

Evaluating and Selecting Your Ideal Steel Structure Stadium Manufacturer

The final selection process uses objective evaluation factors to compare eligible makers in a systematic way. This method makes decisions more open and ensures that the project's needs and the manufacturer's abilities are perfectly matched.

Scorecard-Based Evaluation Process

A full report lets you compare numbers in maker bids across all rating aspects. Technical scoring covers things like structure building skills, the ability to make things very precisely, and ways to make sure that quality is high. Competitive price, payment terms, and estimates of how much the product will cost over its lifetime are all parts of financial assessment. Environmental approvals, ways of getting materials,, and efforts to lower carbon footprints are all parts of sustainability review.

Regional Considerations and Logistical Efficiency

Geographic factors have a big effect on project success. They affect the cost of transportation, the plan for deliveries, and the rules that must be followed in the area. Manufacturers that have well-known supply chains and can make products in their own areas often help with cutting costs and making sure deliveries happen on time. Knowing the rules about building, earthquakes, and the environment in your area makes sure that the steel structure stadium project goes smoothly and follows the rules.

Case Study Analysis and Best Practices

Looking at great stadium projects can help you learn how to choose the right manufacturers. Recent mega-projects show how important it is to pick makers that can build places with 75,000-seat capacities ahead of schedule, even when the weather makes things hard. Galvanized steel makes up about 8,500 tons of the parts used in these projects, which also include solar-ready roof systems to make sure they use eco-friendly energy. Post-event change possibilities help turn Olympic sites into community sports centers, which are useful for the long run for everyone involved.

Conclusion

A structured check of a stadium builder's technical skills, sustainability qualifications, and project performance experience is needed to choose a maker of sustainable steel stadiums. The choice affects not just the short-term success of the building, but also the long-term efficiency and environmental duty of the operation. Successful procurement teams find a balance between great engineering and caring for the environment. They make sure that the manufacturers their teams choose can build world-class sites that meet both performance and sustainability goals while sticking to strict building schedules.

FAQs

What benefits do steel structure stadiums have over conventional concrete building techniques?

Steel arenas are much better for many reasons: they can be built 40% faster, they work better in earthquakes, and they are easier to build around your needs. The high strength-to-weight ratio of steel makes it possible to build longer spans without supports in the middle. This gives people clearer sightlines. Steel structures are also easier to modify and expand later on, and they stay fireproof with the help of special coatings.

How does long-term viability affect the choice of steel stadium builders?

Sustainability factors stress producers that use environmentally friendly materials, make products with a smaller carbon footprint, and follow environmental rules like ISO 14001. These days, procurement focuses on providers that use 90% reusable steel parts and energy-saving manufacturing methods, as well as trash reduction programs that follow the rules for Green Public Procurement and the company's promises to be environmentally responsible.

What kind of upkeep and term benefits can you expect from good steel stadiums?

If you protect them from rust with hot-dip galvanizing, steel arenas last over 50 years. Steel is naturally durable and doesn't need to be replaced often, even when it is exposed to the elements. Modular steel building is 23% cheaper over its entire lifetime than concrete options because it is easy to fix or change parts without harming the strength of the whole structure.

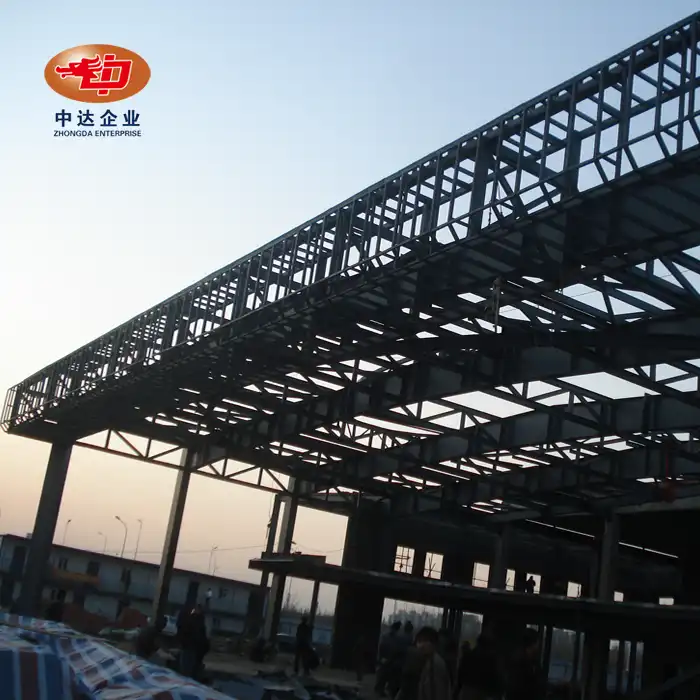

Partner With Zhongda for World-Class Steel Stadium Solutions

Zhongda Steel is a reliable builder of steel structure stadiums. We use eco-friendly production methods and draw on 20 years of experience in engineering. Our 120,000 m² plant in Shenyang has state-of-the-art 100-ton bridge cranes and precision manufacturing tools that can make special stadium parts with great accuracy, speed, and dependability.

Our wide range of certifications, such as ISO 9001, ISO 14001, EN 1090, and OHSAS 45001, make sure that we follow global rules for quality and the environment. We provide arena options that can handle the harshest conditions and keep their shape. With our experience in cold conditions using -60°C Weathering Steel Anti-corrosion Technology and a yearly production capacity of 60,000 tons, we ensure durability.

Our collection includes projects in many countries, such as bridges in Russia and factories in Vietnam. These companies trust us: BMW, China Railway, and CSCEC. Using BIM in our prefabrication process cuts the time it takes to build by 40% compared to older methods. This guarantees that your steel structure stadium project will meet even the tightest schedules. To talk about your exact needs and get a full plan for a sustainable steel structure stadium for sale, email us at Ava@zd-steels.com.

References

American Institute of Steel Construction. (2023). "Specification for Structural Steel Buildings." AISC 360-16.

European Committee for Standardization. (2023). "Execution of Steel Structures and Aluminum Structures." EN 1090-2:2018.

International Organization for Standardization. (2022). "Hot Dip Galvanized Coatings on Fabricated Iron and Steel Articles." ISO 1461:2009.

Building and Construction Authority Singapore. (2023). "Green Building Procurement Guidelines for Steel Structures."

World Green Building Council. (2023). "Sustainable Steel in Sports Infrastructure: Global Best Practices Report."

American Society for Testing and Materials. (2022). "Standard Specification for Structural Steel for Buildings." ASTM A992/A992M-11.