Key design standards for steel structure stadium roofs include a wide range of structural engineering rules that affect the planning, design, and building of long covering systems for sports sites. These standards talk about important things like earthquake protection, heat performance, wind load management, material specs, and load-bearing estimates. These help make sure that the steel structure stadium roof is safe and works well. In today's stadium roof design, modern engineering techniques are combined with the look of the building. This protects the people inside from the weather while keeping the lines of sight clear and improving the sound. Procurement managers, building companies, and engineering firms can make smart choices about which roofing options to use when they understand these design standards. The roofing must meet the needs of each individual project by finding a balance between performance, durability, and cost-effectiveness.

Understanding the Fundamentals of Steel Structure Stadium Roofs

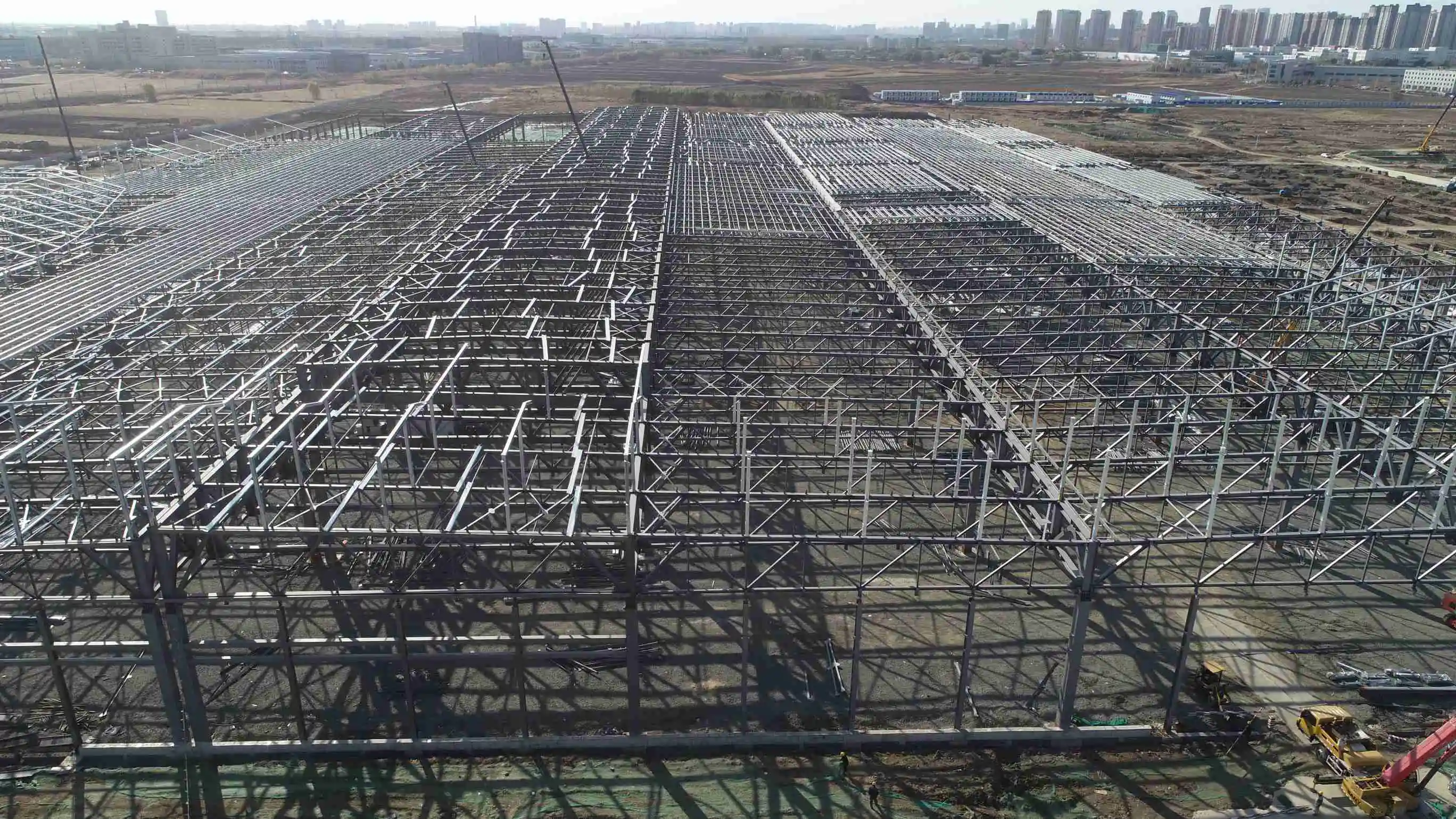

Steel structure stadium roofing systems are complex engineering solutions that blend strength with new ideas in architecture. These frames are made with high-quality steel so that they can span long distances while still being able to handle a wide range of weight conditions.

Core Components and Materials

Today's stadium roofing systems use a number of important parts that work together to make strong, useful buildings. Steel beams, girders, purlins, and link structures made from strong steel metals are important parts of the structure. These materials are treated in special ways, such as by being galvanized and given protective coatings, to make them more resistant to rust and extend their useful lives.

The process of choosing a material looks at many things, such as how it will be used, how it will be affected by the surroundings, and how easy it will be to maintain. Cor-Ten and high-strength low-alloy steels are examples of weather-resistant steel types that work very well in tough weather. Zinc-rich primers and polyurethane topcoats are examples of advanced covering systems that protect surfaces from water, UV rays, and environmental pollutants.

Structural Design Types and Applications

Architectural design, useful needs, and site-specific limitations make a big difference in how steel structure stadium roofs are built. While internal support beams can get in the way of people's line of sight, cantilevered designs don't have them and instead rely on advanced engineering to deal with bending moments and flexion limits. Retractable roof systems are a mix of structural design and mechanical engineering. They let venues change to the weather while keeping the structure safe when in use.

Dome-shaped structures protect from weather and sound very well, but they require careful thought about temperature expansion and wind pressure distribution. Tensile hybrid designs use both steel frames and membrane materials. These lightweight designs are great at both performing well and looking good.

Essential Design Principles and Standards for Steel Structure Stadium Roofs

Comprehensive design standards are the key to successful stadium roofing projects. These standards make sure that the structures meet strict safety rules while also making sure that they work as well as possible for the entire time they are in use.

Load Analysis and Structural Calculations

The most important part of stadium roof design is load assessment, which includes many types of force that buildings need to be able to handle at the same time. The weight of building materials, roofs, and equipment that is permanently fixed, like lighting systems and scoreboards, are all considered dead loads. Live loads are brief loading situations, like repair staff, snow that builds up, and times when equipment is being installed.

When figuring out wind load, one needs to carefully study local weather data and the way that the land itself can change the way that pressure moves across the roof. Seismic design factors include ground motion parameters and structure reaction features to make sure that buildings work well during earthquakes. To keep the building's structural stability, roof snow load estimates look at the roof's shape and the area's weather trends to keep the snow from piling up too much.

Material Standards and Quality Requirements

International design rules like AISC 360, Eurocode 3, and ASCE 7 give a lot of information on how to choose materials and build structures. These guidelines set the least amount of power that is needed, how to test it, and how to make sure that quality is always the same, no matter where or how the project is done.

When choosing a steel grade, it is important to think about how strong it needs to be and how much it will cost. Grades from A36 for basic uses to A992 for high-performance structure parts are usually used. When designing connections, you need to follow the rules for soldered and bolted parts. This makes sure that the pieces can handle the force while still being easy to put together and check.

Integration with Architectural Elements

A successful steel structure stadium roof design requires a perfect balance between useful needs and artistic vision. As it makes sure that all viewers have clear lines of sight from every place, sightline optimization also preserves the overall efficiency of the structure. Acoustics affect both the shape and the materials used in order to better control crowd noise and make words clearer.

Weather protection plans find a balance between the needs of natural lighting and air flow and the needs of covering. Advanced modeling methods help find the best shape for a roof so that rain from the wind can't get in while also helping air flow naturally so that people watching feels more comfortable.

Engineering Challenges and Solutions in Steel Structure Stadium Roof Design

The use of complex shapes and very long lengths in construction projects creates unique problems that need new ideas and complex ways of figuring things out.

Managing Complex Geometries and Large Spans

Modern stadium designs often use uneven shapes that make it hard to use common ways of analyzing structures. Engineers can correctly test how structures behave under different loading conditions with advanced 3D modeling tools. This also helps to optimize member size and connection details. Finite element analysis helps find areas of high stress and patterns of displacement that help make designs better.

Deflection limits and shaking features must be carefully thought about when dealing with large-span needs. Long-span buildings are more affected by dynamic loading from wind and crowd movements. They need special testing to make sure they have enough stiffness and damping qualities.

Fabrication and Construction Considerations

When you choose to prefabricate or field-fabricate something, it has a big effect on the project's total cost-effectiveness, quality control, and timelines. Prefabricated parts have better measurement accuracy and quality control because they are made in controlled settings, but they need to be carefully planned for shipping and installation processes.

Modular construction methods allow parts of a building to be made and put together at the same time, which shortens the length of the overall project. It is easy to safely and correctly place big building parts when you use advanced moving and positioning tools.

Environmental and Sustainability Factors

These days, designers are more focused on protecting the earth and making the best use of resources. Because steel can be repurposed, it has big benefits for environmentally friendly building. For example, more than 90% of the material in structure steel goods is usually recovered. It is better for the earth to use energy-saving methods for production and to optimize movement.

Maintenance-friendly design features make it easier to check and reapply surface treatments. This extends the working lives and minimizes environmental impact. Adding sustainable energy sources like solar panels makes it possible for stadiums to be energy-positive.

Comparative Insights: Steel Structure Stadium Roofs vs. Alternatives

Knowing the pros and cons of different roofing systems helps people make choices that are in line with the needs and limits of a project.

Steel vs. Concrete Roofing Systems

Steel buildings are much lighter than concrete ones, which means that foundations don't need to be as big, and it's possible to build longer spans with fewer supports in the middle. Steel structure stadium roofs are usually better for construction speed because they can be prefabricated and are easier to put together. On the other hand, concrete systems might be better at resisting fire and have thermal mass qualities that help in certain climates.

These systems have very different upkeep needs. For example, steel needs its layer renewed every so often, but for concrete, the focus is on fixing cracks and keeping the surface water-proof. When you want to know the general value of something, you need to look at both its building costs and its upkeep costs over its lifetime.

Traditional vs. Tensile Membrane Integration

Hybrid systems that combine steel frames with tension fabric parts make lightweight structures that are both very efficient and good-looking. These systems usually need less material to work while still offering great safety from the weather and light transfer. But the parts of the membrane roof may need to be replaced more often than with regular roofing materials.

Maintenance entry and checking methods are very different for each type of system. This affects long-term running costs and service needs. It is very important to think about climate when choosing materials because UV exposure and big changes in temperature can affect how well and how long membranes last.

Procurement and Installation Best Practices for Steel Structure Stadium Roofs

Careful planning, strict quality control, and careful source selection during the manufacturing and installation steps are key to delivering a project on time.

Supplier Selection and Quality Assurance

When doing manufacturer evaluations, companies should be at the top of the list if they have shown that they know a lot about structure systems with big spans and have quality standards like ISO 9001 and EN 1090. A project resume review shows that you have worked on projects with similar levels of difficulty and performance needs. An evaluation of technical skills includes methods for quality control, manufacturing tools, and resources for expert support.

To make sure that quality assurance programs follow design specs and industry standards, they need to include installation tracking, material approval, and manufacturing review. Third-party testing services check important things like welding quality and measurement accuracy.

Project Planning and Logistics Coordination

A detailed project schedule lines up the making of project parts with the planning and installation needs of the project. Transportation planning takes into account the needs for crane access and delivery of large parts. These affect both cost and schedule. Weather has an impact on installation windows, especially in areas where work can't happen outside during certain seasons.

Risk management techniques find possible delays and come up with ways to protect project plans and funds. Communication methods make sure that everyone involved knows how things are going and can quickly respond to new problems.

Installation and Quality Control Procedures

Installation must be safe, accurate, and strong. While they're being built, temporary support systems make sure that big parts of structures can be safely put in place and stay stable. Quality control checks make sure that things are lined up correctly, the connections are secure, and the surfaces are ready before moving on to the next steps in the building process.

Post-installation checks record the work that was done and find anything that needs to be fixed before the project is accepted. Warranty terms should clearly explain who is responsible for the quality of the materials and workmanship and for upkeep help during the start-up time.

Conclusion

Key design guidelines for steel structure stadium roofs include a wide range of engineering ideas that make sure modern sports facilities have safe, long-lasting, and affordable roofing options. Knowing about load standards, material specs, and building methods helps people make good choices during both the purchase and installation stages. Steel structures are becoming more popular for new stadiums because they are flexible in terms of design, quick to build, and good for the environment. Choosing the right suppliers, making sure quality is high, and installing things correctly are all very important for getting the best performance and longest life out of something. As technology improves and performance goals change, these design standards are always changing. This means that you have to always pay attention to what is happening in the business and what the best practices are.

FAQs

What determines how long a steel structure stadium roof will last?

Based on the quality of the materials used, how well the roof is taken care of, and how much it is exposed to the elements, a steel structure stadium roof usually lasts between 50 and 75 years. Regular inspections and reapplying the paint can keep the structure intact and make it look good, which can greatly extend its working life.

How do stadium roof design needs change because of wind?

Wind loads are very important for figuring out both how big structures should be and how they should be shaped. Because of their huge, uneven shapes, stadium roofs feel complicated wind pressure patterns. This means that either wind tunnel tests or computational fluid dynamics analysis must be used to figure out exactly how the roof will be loaded and how the structure should respond.

What kind of upkeep should steel stadium roofs systems expect to need?

Maintenance needs include checking on the state of the paint, looking at the structure links from time to time, and cleaning the drainage system. Based on how much the structure is exposed to the elements, protective covering renewing usually happens every 15 to 20 years. Structural checks should be done once a year to keep an eye on performance and find any problems that are forming and need to be fixed.

Partner with Zhongda for Premium Steel Structure Stadium Roof Solutions

Zhongda Steel uses cutting-edge manufacturing technology to create world-class engineering for steel structure stadium roof applications, drawing on decades of experience working on projects around the world. Our EN 1090 compliance and ISO 9001/14001/OHSAS 45001 certifications make sure that all of our work meets the highest quality standards. Plus, our 120,000 m² production site gives us the space and accuracy needed to build complicated stadium roofing systems.

Our advanced BIM-driven prefabrication capabilities and proprietary -60°C Weathering Steel Anti-corrosion Technology deliver superior performance in challenging environments, while our ultra-thick plate cutting accuracy of ±0.2mm ensures perfect fit and assembly. We have completed projects in a wide range of situations, from freezing weather in Russia to factories in Australia and Vietnam. Our clients include China Railway, CSCEC, BMW, and other well-known companies.

We are a top maker of steel structure stadium roofs, and we offer full support from the initial design through installation and ongoing upkeep. Our engineering team has a lot of experience working with clients to make sure that performance and cost-effectiveness are maximized while also making sure that design standards and building rules are followed both globally and locally.

Ready to find out how the knowledge we've built up over the years can help with your next stadium project? If you want to talk to us about technical details or getting a quote for a job, email us at Ava@zd-steels.com.

References

American Institute of Steel Construction. "Steel Design Guide 25: Frame References for Improved Seismic Performance." AISC, 2018.

European Committee for Standardization. "Eurocode 3: Design of Steel Structures - Part 1-1: General Rules and Rules for Buildings." CEN, 2019.

American Society of Civil Engineers. "Minimum Design Loads and Associated Criteria for Buildings and Other Structures." ASCE 7-22 Standard, 2022.

International Association for Bridge and Structural Engineering. "Structural Engineering Documents: Steel Structures for Large Span Buildings." IABSE, 2020.

Construction Industry Research and Information Association. "Guide to Long-Span Steel Frame Design." CIRIA Report C654, 2021.

International Code Council. "International Building Code: Chapter 16 - Structural Design Requirements." ICC, 2021.