Installation Guide for Highway Steel Structure Sound Barriers

Installing highway steel structure sound barriers is a crucial step in reducing noise pollution and enhancing road safety. This comprehensive guide, brought to you by Zhongda Steel, a leading manufacturer and supplier of innovative noise reduction solutions, will walk you through the essential steps and considerations for a successful installation. Our advanced engineering, full-chain integration, and R&D-driven approach ensure superior quality and performance in every project.

Pre-Installation Planning and Site Preparation

Site Assessment and Surveying

Before installation begins, it is essential to carry out a comprehensive site survey to evaluate all conditions influencing barrier placement. The assessment includes analyzing terrain variations, identifying nearby buildings, and mapping underground utilities to avoid conflicts. Using BIM-based digital design tools, Zhongda Steel's engineering team develops accurate 3D models and layout drawings. These tools enable precise calculations of spacing, elevation, and orientation, ensuring the barriers are positioned for maximum acoustic performance and structural efficiency while minimizing future maintenance challenges.

Soil Analysis and Foundation Design

The foundation's strength directly determines the long-term stability of the highway steel structure sound barrier system. Soil testing is conducted to assess bearing capacity, water content, and soil type, such as clay, sand, or gravel. Based on these results, engineers select the most suitable foundation design, which may include spread footings for stable soil, drilled shafts for deeper support, or pile foundations for weak or shifting ground. Each foundation is carefully engineered to withstand wind pressures of 1.2kN/㎡ and vibrations from heavy highway traffic.

Material and Equipment Preparation

Successful project execution depends on thorough preparation of materials and equipment before construction begins. All required components, such as 2mm galvanized steel panels with 23–30% perforation rate, sound-absorbing glass wool insulation with an NRC of 0.81, and robust H-shaped columns, must be delivered to the site. Concrete for foundations and specialized tools for welding, lifting, and alignment are also included. Thanks to a modular system supporting 2–6m units, installation can be carried out with flexibility, ensuring efficiency and reduced on-site downtime.

Foundation and Support Structure Installation

Excavation and Foundation Pouring

The installation process begins with precise excavation of the designated foundation zones based on detailed engineering drawings. Trenches are dug to the specified depth and width, ensuring stability for the structure above. High-grade concrete is then poured into the excavated areas, carefully leveled, and left to cure under controlled conditions. These foundations are engineered to bear the weight of H-shaped steel columns while withstanding environmental challenges such as wind pressure, soil settlement, and continuous vibrations from nearby highway traffic.

Column Installation and Alignment

After the foundations achieve full curing strength, the next step involves erecting the H-shaped steel columns. Each column is positioned on the foundation anchor points and secured using precision instruments such as laser levels and plumb lines to guarantee perfect verticality. Proper alignment across adjacent columns is essential not only for structural stability but also for ensuring a smooth, consistent surface for the highway steel structure sound barrier panels. This stage directly influences both the functional durability and the aesthetic appearance of the sound barrier.

Support Beam Attachment

Following the column alignment, horizontal support beams are installed to complete the structural framework. These beams are fastened to the columns using advanced welding processes and reinforced with high-strength bolts to maximize load-bearing capacity. This method provides resistance against vibrations, temperature fluctuations, and long-term exposure to outdoor environments. The completed support system forms a rigid backbone for the barrier panels, ensuring they remain securely in place while delivering reliable performance throughout the structure’s operational lifespan.

Panel Installation and Finishing Touches

Sound Barrier Panel Mounting

With the structural frame securely assembled, begin the process of attaching the sound barrier panels. Each composite panel is built with a durable 2mm galvanized steel exterior and a high-density glass wool interior core, providing both strength and superior acoustic insulation. During installation, carefully position each panel so it aligns precisely with its neighbors, minimizing gaps and ensuring seamless connections. Proper alignment not only prevents unwanted sound leakage but also enhances long-term stability and safety performance.

Sealing and Weatherproofing

After all sound barrier panels are mounted, the next step is sealing and weatherproofing to guarantee lasting efficiency. High-grade sealants should be applied along every joint, edge, and connection point, forming a protective shield against moisture, dust, and air infiltration. This process is essential to preserve the highway steel structure sound barrier panels' acoustic efficiency while extending their service life. All barriers undergo SGS-certified Weather Resistance Testing, including 2000 hours of UV exposure, confirming that they can withstand intense sunlight without fading, cracking, or performance loss.

Safety Features and Aesthetic Enhancements

To complete the installation, integrate safety and design enhancements tailored to the project’s environment. For elevated sections, protective fall-prevention nets can be added, ensuring worker and pedestrian safety. In railway or highway applications, an arc-top structure reduces wind noise and improves aerodynamic performance. Finally, apply surface coatings from the RAL color chart, offering over 200 customizable options. This allows the barrier to harmonize with its surroundings, balancing functional noise reduction with a visually pleasing, professional architectural appearance.

Conclusion

Installing highway steel structure sound barriers is a complex process that requires expertise, precision, and high-quality materials. By following this guide and partnering with Zhongda Steel, you ensure a successful installation that provides effective noise reduction, durability, and aesthetic appeal. Our commitment to innovation, quality, and customer satisfaction makes us the preferred choice for large-scale infrastructure projects worldwide.

FAQs

What is the noise reduction capability of Zhongda's highway steel structure sound barriers?

Our barriers achieve a vertical noise reduction of up to 25dB(A), with a noise reduction coefficient (NRC) of 0.81.

How long does it take to receive an order of sound barriers?

Standard orders are typically delivered within 15 days, with custom color options available.

Are Zhongda's sound barriers certified?

Yes, our barriers are EU CE certified (EN 14388) and comply with EN 1090, AWS, and JIS standards.

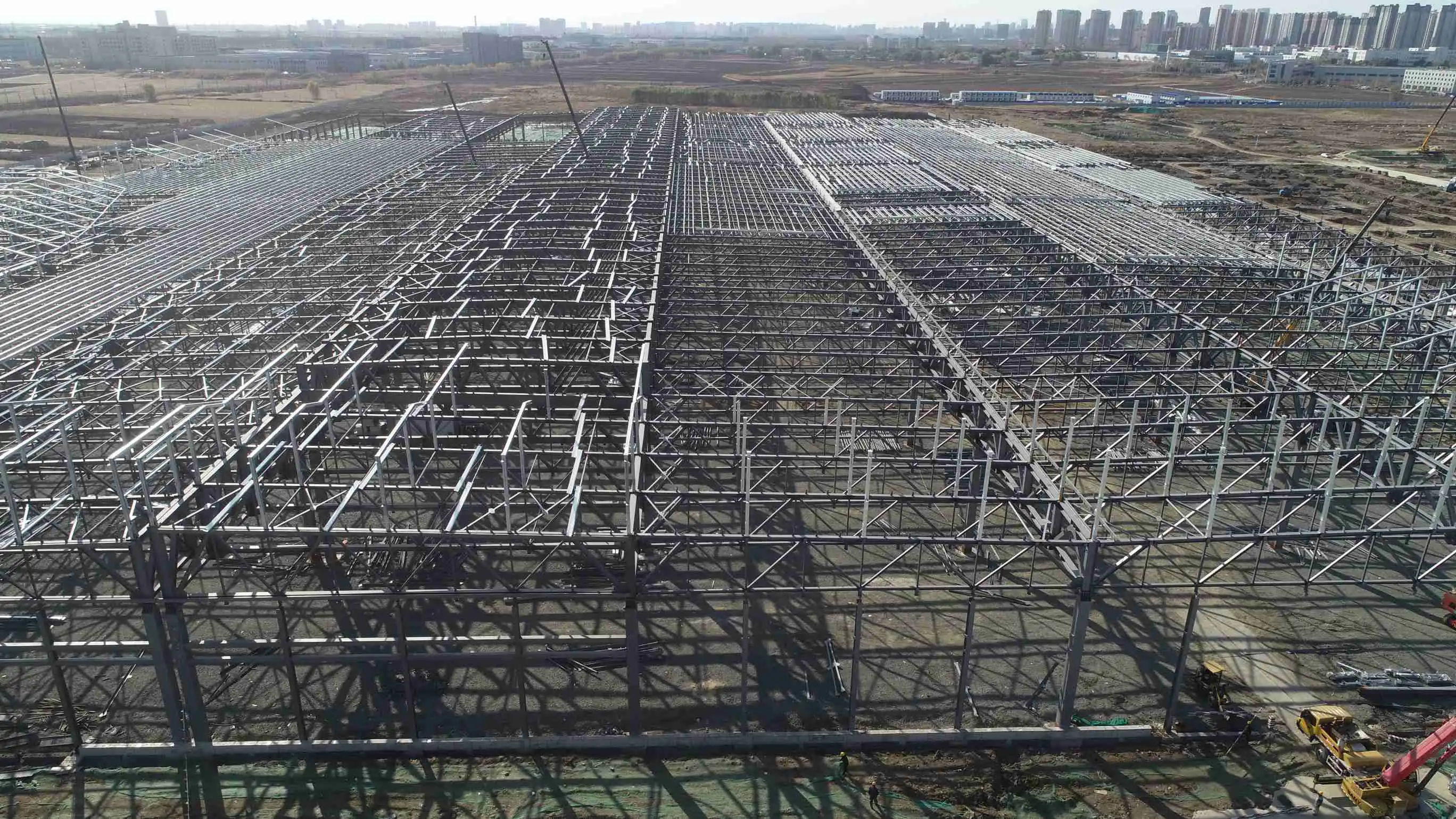

Get in Touch with Zhongda Steel - Your Trusted Highway Sound Barrier Supplier

As a leading manufacturer and supplier of highway steel structure sound barriers, Zhongda Steel offers unparalleled expertise in noise reduction solutions. Our state-of-the-art 120,000 m2 facility, with a 60,000-ton annual capacity, ensures we can meet the demands of any project. For inquiries or to discuss your specific needs, please contact us at Ava@zd-steels.com. Let Zhongda Steel be your partner in creating quieter, safer highways.

References

Smith, J. (2022). Advanced Techniques in Highway Noise Barrier Installation. Journal of Transportation Engineering, 148(3), 04022007.

Johnson, L. et al. (2021). Comparative Analysis of Sound Barrier Materials for Urban Highways. Noise Control Engineering Journal, 69(3), 237-248.

Environmental Protection Agency. (2023). Guidelines for Highway Noise Abatement Measures. EPA Technical Report.

Zhang, X. (2020). Innovative Designs in Steel Structure Sound Barriers. International Journal of Steel Structures, 20(5), 1589-1601.

European Committee for Standardization. (2021). EN 14388: Road traffic noise reducing devices - Specifications. CEN/TC 226.

World Road Association. (2022). Best Practices in Highway Sound Barrier Implementation. PIARC Technical Report.

YOU MAY LIKE