The Fundamentals of Steel Plate Girder Design

Composition and Structure

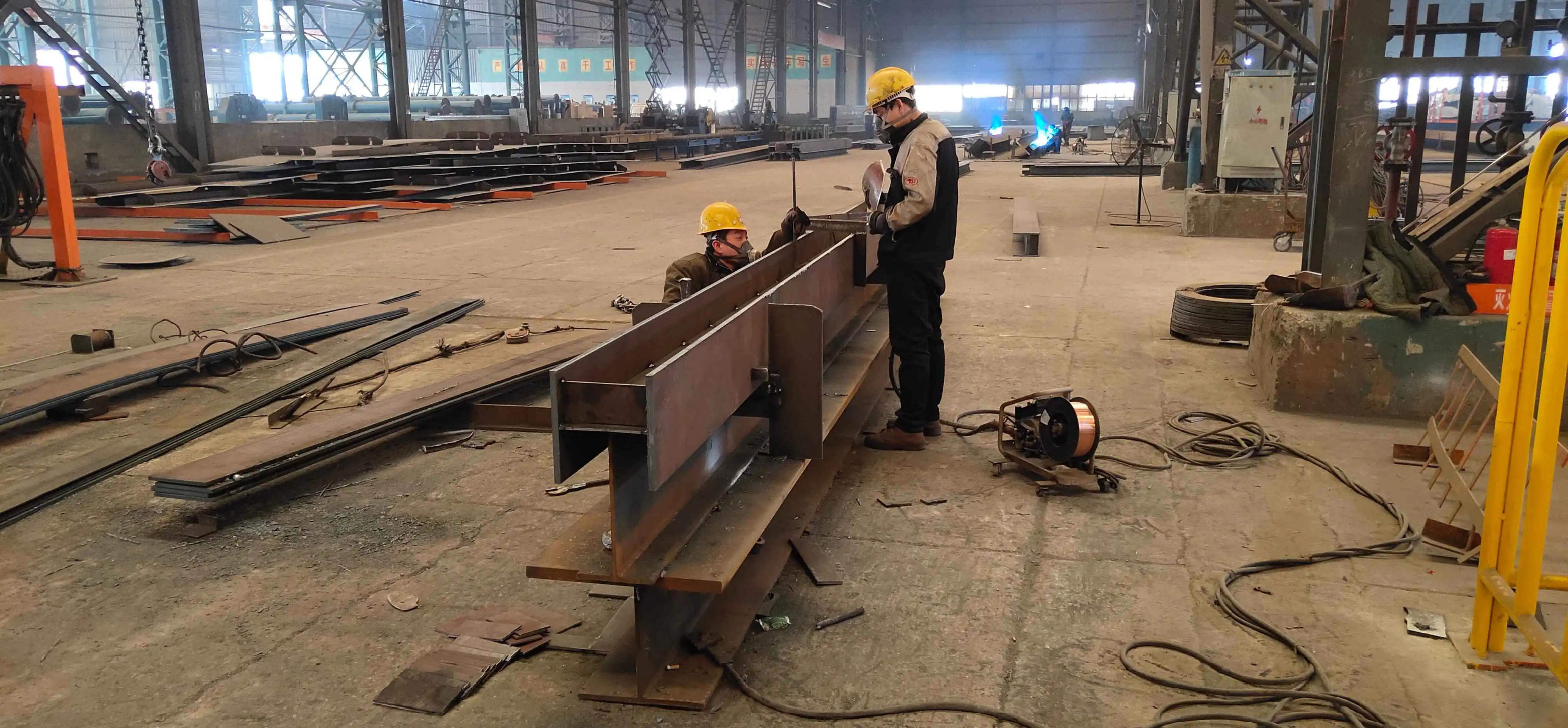

Steel plate girders consist of three main components: the web, flanges, and stiffeners. The web is a vertical plate that bears shear forces, while the flanges are horizontal plates at the top and bottom that resist bending moments. Stiffeners are additional plates welded to the web to prevent buckling under heavy loads.

At Zhongda Steel, we utilize high-strength Q420qE steel, capable of maintaining impact toughness of ≥34J even at temperatures as low as -40℃, ensuring reliability in harsh climates. Our advanced laser cutting technology achieves precision within ±0.5mm, while our flange thicknesses range from 14 to 80mm, accommodating diverse project requirements.

Load Distribution and Stress Management

The design of steel plate girders revolves around efficient load distribution and stress management. The web transfers shear forces along the girder's length, while the flanges handle compressive and tensile stresses from bending moments. This configuration allows for optimal material usage, resulting in a lightweight yet incredibly strong structure.

Our engineering team employs sophisticated analysis tools to optimize load distribution, ensuring each girder is tailored to its specific application. This approach has proven successful in projects like the Alaska Polar Highway Bridge, where our weather-resistant girders withstand extreme cold and challenging climate conditions.

Customization and Adaptability

One of the key advantages of steel plate girders is their adaptability to various project requirements. Factors such as span length, load capacity, and environmental conditions all influence the design process. At Zhongda Steel, we offer customizable dimensions and steel grades to precisely meet unique project specifications.

Our expertise in complex, large-scale projects allows us to provide innovative solutions for challenging applications. For instance, our work on Nordic Fjord Heavy-Load Bridges showcases our ability to create corrosion-resistant girders specifically designed for marine environments, ensuring long-term durability and performance.

Advanced Manufacturing Techniques for Steel Plate Girders

Precision Fabrication

Modern steel plate girder manufacturing relies heavily on precision fabrication techniques. At Zhongda Steel, we employ state-of-the-art CNC machinery and automated welding lines to ensure exceptional accuracy in every component. Our advanced laser cutting technology achieves tolerances of ±0.5mm, guaranteeing perfect fit and alignment during assembly.

This level of precision is crucial for projects like the Shenyang Dongta Cross-Hunhe River Bridge, where our 18,000-ton product structure demanded flawless execution for seamless river crossing. Our commitment to precision extends to every aspect of production, from initial cutting to final assembly.

Welding and Assembly Innovations

Welding plays a critical role in steel plate girder construction, determining the overall strength and durability of the final product. Zhongda Steel utilizes advanced welding techniques, including submerged arc welding and flux-cored arc welding, to ensure strong, consistent joints throughout the girder.

Our bolted assembly method has resulted in a 60% efficiency gain compared to traditional techniques. This innovation not only speeds up on-site installation but also allows for easier maintenance and potential disassembly if required in the future. The success of this approach is evident in projects like the Jingha Expressway expansion, where rapid assembly was crucial to minimizing traffic disruptions.

Quality Control and Testing

Rigorous quality control is essential in steel plate girder manufacturing. At Zhongda Steel, we implement a comprehensive quality assurance program that includes non-destructive testing (NDT) for structural integrity, dimensional accuracy checks, material composition verification, and welding quality inspections.

Additionally, we conduct load testing to ensure each girder performs as expected under stress. Our products are fully compliant with international standards such as ASTM, EN, and JIS, guaranteeing quality and reliability. This commitment to quality is exemplified in our ASTM A709 Gr.50W certification and comprehensive fatigue test reports.

Enhancing Durability and Performance of Steel Plate Girders

Corrosion Protection Strategies

Corrosion poses a significant threat to steel structures, especially in harsh environments. Zhongda Steel addresses this challenge through advanced corrosion protection techniques. We employ a double protection system, combining spray coating with a high-performance topcoat, adhering to GB/T 30790 standards.

This multi-layer approach provides superior resistance to environmental factors, extending the lifespan of our steel plate girders. The effectiveness of our corrosion protection is demonstrated in projects like the Nordic Fjord Heavy-Load Bridges, where our girders withstand constant exposure to marine elements.

High-Performance Materials

The choice of materials significantly impacts the performance and longevity of steel plate girders. Zhongda Steel utilizes high-strength, weather-resistant steel grades that offer superior mechanical properties and corrosion resistance. Our Q420qE steel, for instance, maintains excellent impact toughness even at extremely low temperatures, making it ideal for projects in Arctic regions.

By carefully selecting and engineering materials, we ensure our girders can withstand extreme conditions while maintaining their structural integrity. This approach has been particularly successful in projects like the Australian mining crushing stations, where our custom-designed heavy-duty girders endure harsh mining environments.

Innovative Design Solutions

At Zhongda Steel, we continuously innovate to enhance the performance of our steel plate girders. Our engineering team leverages advanced simulation tools and real-world data to optimize designs for specific applications. This might involve incorporating unique geometries, utilizing hybrid materials, or implementing novel stress distribution techniques.

Our commitment to innovation is backed by comprehensive R&D capabilities, allowing us to develop cutting-edge solutions for even the most challenging projects. From optimizing weight-to-strength ratios to enhancing fatigue resistance, we push the boundaries of what's possible in steel plate girder design.

Conclusion

Understanding the engineering behind steel plate girders reveals the intricate balance of design, materials, and manufacturing that goes into these crucial structural components. At Zhongda Steel, we combine advanced technology, expert engineering, and unwavering commitment to quality to produce steel plate girders that set new standards in the industry. Our innovative approaches to fabrication, corrosion protection, and customization ensure that each girder we produce is optimized for its specific application, delivering unparalleled performance and longevity.

Contact Us

to elevate your next infrastructure project with Zhongda Steel's cutting-edge steel plate girders? Experience the perfect blend of innovation, precision, and durability that only a global leader in steel solutions can provide. Contact us today at Ava@zd-steels.com to discuss how our expertly engineered steel plate girders can bring your visionary projects to life, ensuring structural integrity and longevity for decades to come.