Components and Design of Steel Truss Beams

Essential Elements of a Steel Truss Beam

Steel truss beams consist of several key components that work together to provide structural integrity and load-bearing capacity. The main elements include:

- Top chord: The upper horizontal member of the truss

- Bottom chord: The lower horizontal member of the truss

- Web members: Diagonal or vertical elements connecting the top and bottom chords

- Nodes: Points where web members intersect with the chords

- Gusset plates: Connectors used to join truss members at nodes

These components are carefully engineered to distribute forces efficiently throughout the structure, allowing steel truss beams to support substantial loads while remaining relatively lightweight.

Common Truss Configurations

Steel truss beams come in various configurations, each designed to meet specific structural requirements and aesthetic preferences. Some popular truss designs include:

- Warren truss: Features equilateral triangles with alternating diagonal web members

- Pratt truss: Incorporates vertical web members and diagonal members that slope towards the center

- Howe truss: Similar to Pratt truss but with diagonal members sloping away from the center

- Fink truss: Utilizes multiple diagonal web members to create a series of smaller triangles

- Bowstring truss: Features a curved top chord resembling an arch

At Zhongda Steel, our expert engineers can help you select the most suitable truss configuration for your project, ensuring optimal performance and cost-effectiveness.

Advantages of Steel Truss Beam Construction

Steel truss beams offer numerous benefits that make them a preferred choice in modern construction:

- High strength-to-weight ratio: Allows for longer spans with minimal material usage

- Versatility: Adaptable to various architectural designs and load requirements

- Cost-effectiveness: Reduces overall construction costs due to efficient material use

- Prefabrication potential: Can be manufactured off-site for quicker assembly and installation

- Durability: Resistant to corrosion and weathering when properly treated

- Ease of maintenance: Simple to inspect and repair compared to solid beam structures

These advantages, combined with Zhongda Steel's expertise in precision manufacturing and innovative anti-corrosion technologies, ensure that our steel truss beams deliver exceptional performance and longevity.Applications of Steel Truss Beams in Various Industries

Steel Truss Beams in Bridge Construction

Steel truss beams play a crucial role in bridge engineering, offering an efficient solution for spanning long distances. Their application in bridge construction includes:

- Through truss bridges: Where the roadway passes between parallel trusses

- Deck truss bridges: With the roadway situated on top of the truss structure

- Pony truss bridges: Featuring lower trusses with no overhead bracing

Zhongda Steel's expertise in weathering steel technology and precision fabrication makes us an ideal partner for bridge projects, even in challenging environments like the Arctic bridges we've supplied to Russia.Steel Truss Beams in Commercial and Industrial Buildings

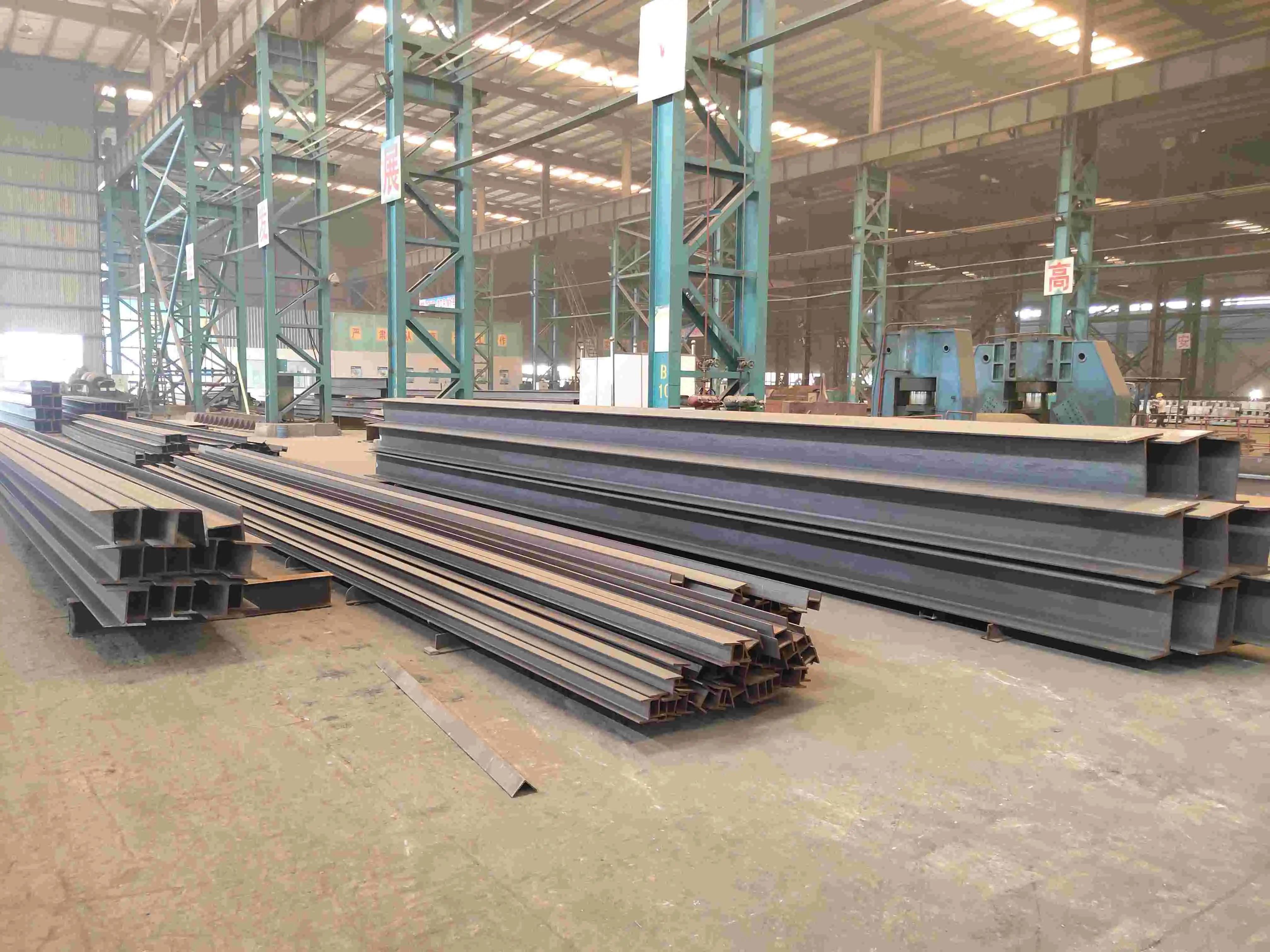

In commercial and industrial construction, steel truss beams are widely used for their ability to create large, open spaces. Common applications include:

- Warehouses and distribution centers

- Manufacturing facilities

- Aircraft hangars

- Sports arenas and stadiums

- Convention centers

Our BIM-driven prefabrication process ensures that steel truss beams for these projects are manufactured with exceptional precision, reducing on-site assembly time and costs.Residential and Architectural Uses of Steel Truss Beams

Steel truss beams are increasingly popular in residential architecture and unique building designs. They are used in:

- Modern homes with open floor plans

- Loft conversions and attic renovations

- Exposed ceiling designs for aesthetic appeal

- Carports and garages

- Innovative architectural structures

Zhongda Steel's ability to work with ultra-thick plates and achieve tight tolerances (±0.2mm) allows us to create custom steel truss beams that meet the exacting standards of architects and homeowners alike.Design Considerations and Engineering Challenges

Load Analysis and Structural Calculations

Designing effective steel truss beams requires careful consideration of various factors:

- Dead loads: The weight of the structure itself and permanent fixtures

- Live loads: Temporary or movable loads, such as people, furniture, or vehicles

- Environmental loads: Wind, snow, seismic activity, and other natural forces

- Load distribution: Ensuring even stress distribution across the truss members

- Deflection limits: Maintaining structural integrity under maximum load conditions

Our engineering team at Zhongda Steel utilizes advanced software and decades of experience to perform precise load analyses and structural calculations, ensuring that each steel truss beam meets or exceeds relevant safety standards.Material Selection and Quality Control

The performance of steel truss beams heavily depends on the quality of materials used. Key considerations include:

- Steel grade selection based on strength requirements and environmental conditions

- Corrosion resistance, especially for exposed or coastal applications

- Weldability and fabrication ease

- Quality control measures throughout the manufacturing process

- Compliance with international standards and certifications

Zhongda Steel's commitment to quality is evident in our ISO 9001/14001/OHSAS 45001 and EN 1090 certifications, ensuring that our steel truss beams meet the highest industry standards.Installation and Maintenance Best Practices

Proper installation and ongoing maintenance are crucial for the longevity and performance of steel truss beams:

- Precise alignment and connection of truss members during assembly

- Use of appropriate fasteners and welding techniques

- Regular inspections to detect potential issues early

- Proper surface treatment and repainting to prevent corrosion

- Addressing any deformation or damage promptly

Zhongda Steel provides comprehensive support, including installation guidelines and maintenance recommendations, to ensure the optimal performance of our steel truss beams throughout their lifespan.Conclusion

Steel truss beams are versatile and efficient structural elements that play a vital role in modern construction. Their ability to span long distances while maintaining strength and stability makes them invaluable in various applications, from bridges and industrial facilities to residential architecture. As we've explored, the design, material selection, and proper installation of steel truss beams are critical factors in their performance. With Zhongda Steel's expertise in precision manufacturing, innovative technologies, and commitment to quality, we continue to push the boundaries of what's possible with steel truss beam construction, delivering exceptional solutions for projects around the globe.

FAQs

What is the maximum span a steel truss beam can cover?

The maximum span depends on various factors, including the truss design, load requirements, and material properties. Some steel truss bridges can span over 500 meters.

Are steel truss beams more expensive than solid beams?

While initial costs may be higher, steel truss beams often prove more cost-effective in the long run due to their efficient use of materials and reduced overall structural weight.

How long do steel truss beams typically last?

With proper maintenance and corrosion protection, steel truss beams can last 50-100 years or more, depending on environmental conditions and usage.

Expert Steel Truss Beam Solutions | Zhongda Steel

At Zhongda Steel, we specialize in manufacturing high-quality steel truss beams for projects worldwide. Our state-of-the-art 120,000 m2 facility, combined with BIM-driven prefabrication and ultra-thick plate cutting technology, enables us to deliver precision-engineered steel solutions. As a trusted supplier to global industry leaders, we offer unparalleled expertise in steel truss beam design and fabrication. Contact us at Ava@zd-steels.com to discuss your project requirements and experience the Zhongda Steel difference.

References

Smith, J.D. (2018). "Structural Steel Design: Principles and Applications." Engineering Press, New York.

Johnson, R.M. (2020). "Advanced Truss Analysis for Modern Construction." Building Science Quarterly, 45(2), 78-92.

Brown, A.L. & Thompson, C.K. (2019). "Steel Truss Beams in Bridge Engineering: A Comprehensive Review." Journal of Structural Engineering, 33(4), 412-428.

Zhang, X.Y. (2021). "Innovations in Steel Truss Beam Fabrication: From Design to Installation." International Conference on Structural Engineering and Construction Management, Conference Proceedings, 156-170.

Miller, E.S. (2017). "Corrosion Prevention Strategies for Steel Structures in Harsh Environments." Materials Protection and Performance, 29(3), 67-82.

Anderson, P.R. & Lee, S.H. (2022). "Optimizing Steel Truss Beam Design for Sustainable Construction." Journal of Green Building, 17(1), 23-39.