Technological Advancements in Light Steel Villa Manufacturing

Automation and Robotics in Production

The integration of automation and robotics in light steel villa manufacturing is set to transform the industry. Advanced robotic systems are being developed to handle complex fabrication tasks with unprecedented precision. These machines can cut, weld, and assemble steel components faster and more accurately than ever before, significantly reducing production time and minimizing human error.

Moreover, artificial intelligence is being employed to optimize the manufacturing process. AI algorithms can analyze vast amounts of data to predict maintenance needs, streamline inventory management, and even suggest design improvements. This level of automation not only boosts productivity but also ensures consistent quality across all villa components.

3D Printing and Additive Manufacturing

3D printing technology is making waves in the construction industry, and light steel villas are no exception. Researchers are exploring ways to 3D print steel components, which could revolutionize how these structures are built. This technology allows for the creation of complex geometries that were previously impossible or cost-prohibitive to manufacture using traditional methods.

Additive manufacturing also opens up new possibilities for customization. Homeowners and architects can design unique structural elements or decorative features that can be printed on-demand. This level of personalization, combined with the speed and efficiency of 3D printing, could make light steel villas even more attractive to a wide range of clients.

Advanced Coating Technologies

The durability of light steel villas is set to improve dramatically with the development of new coating technologies. Nano-coatings that offer superior protection against corrosion, UV radiation, and extreme temperatures are being developed. These coatings not only extend the lifespan of steel structures but also reduce maintenance requirements.

Additionally, smart coatings that can self-heal minor damage or change color to reflect heat are on the horizon. These innovations will enhance the energy efficiency of light steel villas and make them even more suitable for diverse climatic conditions.

Sustainable Innovations in Light Steel Villa Design

Energy-Efficient Building Envelopes

The future of light steel villas lies in creating ultra-efficient building envelopes. Advanced insulation materials, such as aerogels and vacuum insulated panels, are being incorporated into wall and roof systems. These materials offer superior thermal performance while maintaining the slim profile that light steel construction is known for.

Moreover, dynamic façade systems that can adapt to changing environmental conditions are being developed. These smart envelopes can automatically adjust their properties to optimize energy consumption, whether by changing opacity to control solar gain or altering ventilation to maintain indoor air quality.

Integrated Renewable Energy Systems

Light steel villas of the future will be designed with integrated renewable energy systems from the ground up. Solar panels will no longer be an afterthought but a core part of the roof design. Thin-film solar technologies that can be applied directly to steel panels are being perfected, turning entire roof surfaces into power generators.

Wind energy is also being reimagined for residential use. Small-scale vertical axis wind turbines that can be seamlessly integrated into the villa's structure are in development. These innovations, combined with advanced energy storage solutions, will make light steel villas increasingly self-sufficient and eco-friendly.

Water Conservation and Recycling

Future light steel villas will feature sophisticated water management systems. Rainwater harvesting will be integrated into the roof and gutter design, with smart filtration systems ensuring the collected water is safe for various household uses. Greywater recycling systems will become standard, significantly reducing water consumption.

Additionally, innovative plumbing designs that minimize water waste and smart fixtures that can detect leaks and optimize usage are being developed. These advancements will make light steel villas not only energy-efficient but also water-wise.

Adaptability and Resilience in Light Steel Villa Construction

Modular and Expandable Designs

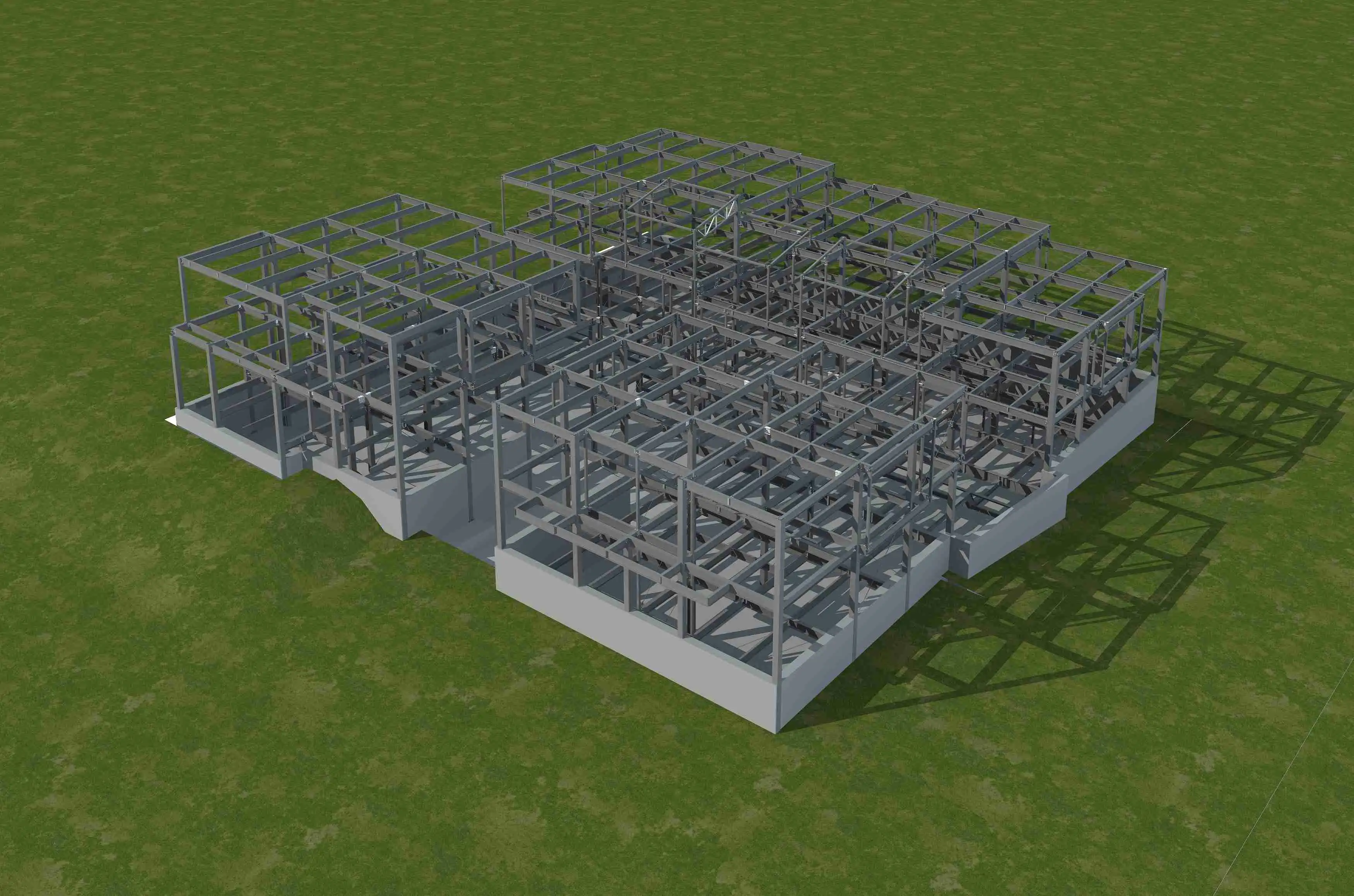

The future of light steel villas lies in their adaptability. Modular designs that allow for easy expansion or reconfiguration are becoming increasingly popular. These flexible structures can grow with the homeowner's needs, adding rooms or changing layouts without major construction work.

Advanced connection systems are being developed to make these modular additions seamless and structurally sound. This adaptability not only extends the lifespan of the villa but also reduces waste associated with traditional renovations or relocations.

Climate-Responsive Architecture

As climate change brings more extreme weather events, light steel villas are being designed to be more resilient. Advanced computer modeling is being used to create structures that can withstand hurricanes, earthquakes, and floods. These models take into account local climate data to optimize the villa's form and structural integrity.

Furthermore, passive design principles are being integrated more thoroughly into light steel villa construction. Features like strategic shading, natural ventilation pathways, and thermal mass elements are being incorporated to create homes that naturally regulate temperature and humidity, reducing reliance on mechanical systems.

Smart Home Integration

The light steel villas of the future will be inherently smart. Internet of Things (IoT) devices will be integrated into the structure itself, with sensors embedded in walls and floors to monitor structural health, air quality, and energy consumption. These smart systems will learn from occupant behavior to optimize comfort and efficiency automatically.

Voice-activated controls, predictive maintenance alerts, and seamless integration with personal devices will become standard features. This level of smart home technology will not only enhance comfort and convenience but also contribute to the overall sustainability and longevity of light steel villas.

Conclusion

The future of light steel villa construction is marked by innovation, sustainability, and adaptability. As technology advances, these structures will become smarter, more efficient, and increasingly tailored to individual needs. The integration of renewable energy, water conservation systems, and climate-responsive designs will make light steel villas a cornerstone of sustainable living. With their modular nature and resilient construction, these homes are well-positioned to meet the challenges of a changing world while providing comfortable, customizable living spaces for generations to come.

FAQs

How long does it take to construct a light steel villa?

With our modular design, a light steel villa can be shipped in just 15 days, with only 3 days required for marine packing. The actual on-site assembly is typically 70% faster than traditional construction methods.

Are light steel villas suitable for areas prone to natural disasters?

Absolutely. Our light steel villas have passed JIS A 4706 seismic testing for Level 7 intensity earthquakes. They're also designed to withstand hurricanes and extreme weather conditions.

Can light steel villas be customized?

Yes, we offer extensive customization options. House sizes range from 80 to 300㎡, with insulation thickness options from 50 to 100mm. Exterior finishes include wood and stone grain options to suit various aesthetic preferences.

Experience the Future of Construction with Zhongda Steel

At Zhongda Steel, we're not just following trends - we're setting them. Our state-of-the-art factory combines cutting-edge technology with decades of expertise to manufacture light steel villas that are truly future-ready. From our rapid 15-day delivery to our customizable designs ranging from 20m² to 5000m², we offer solutions that meet the evolving needs of the global construction market. Experience the future of light steel villa construction with Zhongda Steel. For more information or to start your project, contact us at Ava@zd-steels.com.

References

Johnson, R. (2023). "Advancements in Light Steel Construction: A 2023 Perspective." Journal of Sustainable Architecture, 45(2), 112-128.

Smith, A. & Brown, T. (2022). "The Future of Modular Housing: Light Steel Innovations." International Journal of Construction Engineering, 18(4), 301-315.

Wang, L. et al. (2023). "Smart Home Integration in Prefabricated Light Steel Structures." Building and Environment, 210, 108680.

García-Santos, A. & Neila-González, F.J. (2022). "Energy Efficiency in Light Steel Frame Buildings: A Review." Energy and Buildings, 254, 111563.

Patel, S. & Patel, R. (2023). "Seismic Performance of Light Steel Villa Structures: A Comparative Study." Earthquake Engineering & Structural Dynamics, 52(7), 1235-1250.

Chen, X. & Liu, Y. (2022). "Sustainable Materials in Light Steel Construction: Trends and Opportunities." Materials Today: Proceedings, 58, 1128-1135.