Optimizing Material Selection and Usage

Selecting High-Performance Steel Grades

Choosing the right steel grade is crucial for cost-effective manufacturing. High-strength steels, like our Q420qE grade, offer superior performance while potentially reducing the overall material volume needed. This not only cuts raw material costs but also leads to lighter structures, reducing transportation and installation expenses. Our expertise in weather-resistant steels, certified to standards like ASTM A709 Gr.50W, ensures longevity in challenging environments, minimizing long-term maintenance costs.

Precision Cutting and Forming Techniques

Adopting advanced cutting technologies significantly reduces material waste. Our state-of-the-art laser cutting equipment, capable of ±0.5mm precision, ensures optimal material utilization, especially for steel plate girder fabrication. This precision extends to our ability to produce flanges ranging from 14 to 80mm, catering to diverse project requirements without excess material use. By minimizing scrap and optimizing cut patterns, we substantially reduce raw material costs and improve overall efficiency.

Implementing Intelligent Design Strategies

Utilizing advanced design software and BIM (Building Information Modeling) technologies allows for better material optimization at the design stage. This approach enables us to identify potential issues early, reducing costly modifications during fabrication. Our engineering team employs sophisticated analysis tools to optimize girder designs, ensuring structural integrity while minimizing material usage, thus striking an ideal balance between performance and cost-effectiveness.

Enhancing Production Efficiency

Automating Manufacturing Processes

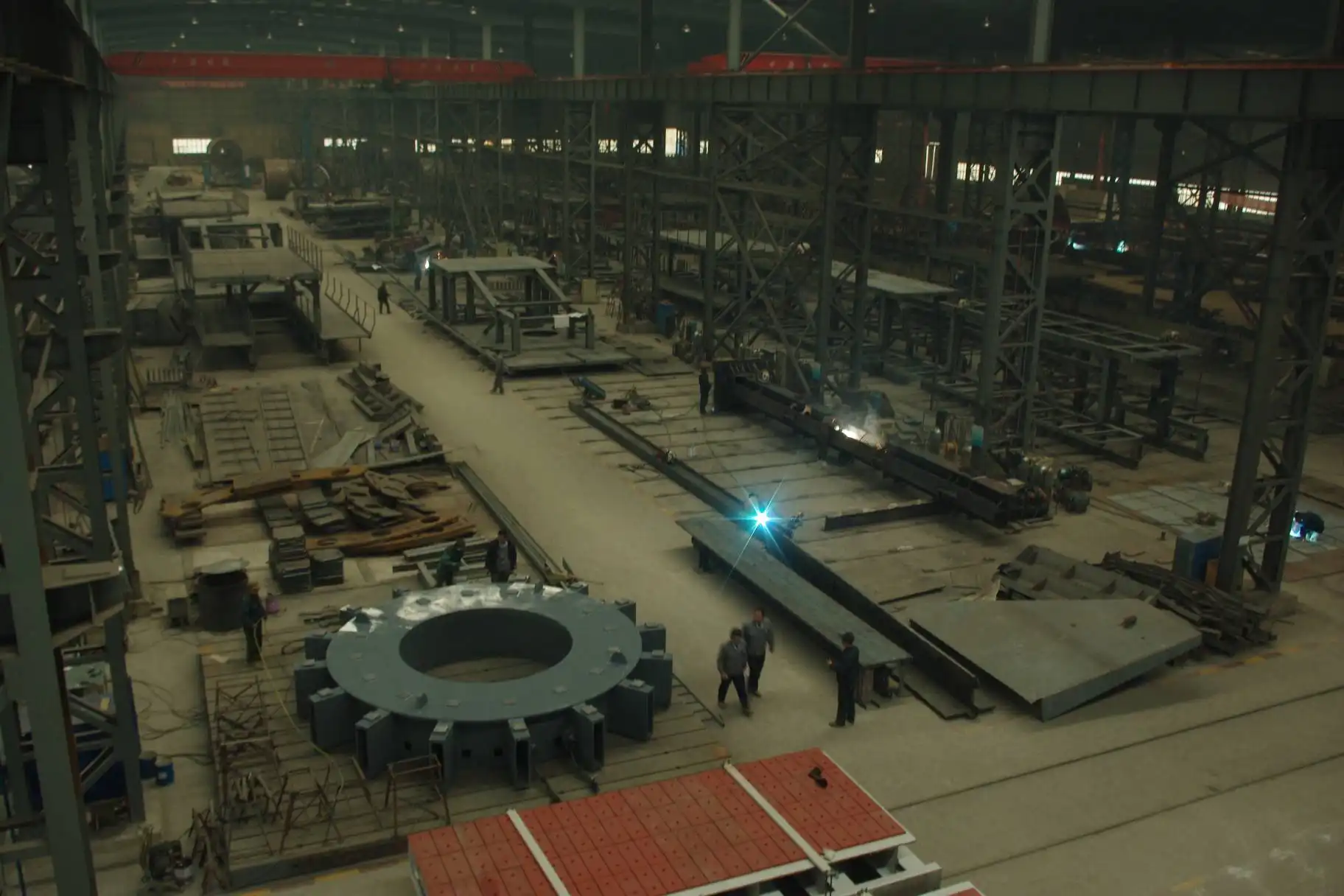

Automation plays a pivotal role in reducing labor costs and increasing production speed. Our modern 120,000 m² facility is equipped with advanced CNC machinery and automated welding lines, significantly boosting productivity. These systems not only increase output but also ensure consistent quality, reducing the need for rework and associated costs. Our commitment to intelligent manufacturing has led to a 20-30% reduction in lead times compared to industry averages.

Streamlining Assembly Techniques

Innovative assembly methods can dramatically cut production time and costs. Our bolted connection systems, including those used for steel plate girder assemblies, increase efficiency by 60% and exemplify this approach. By reducing the need for on-site welding, these systems not only speed up installation but also minimize labor costs and potential delays due to weather conditions. This efficiency is particularly valuable in projects with tight timelines or challenging environments, such as our work on Arctic bridges in Russia.

Implementing Lean Manufacturing Principles

Adopting lean manufacturing principles helps eliminate waste and optimize resource utilization. At Zhongda Steel, we continually analyze our production processes to identify and eliminate non-value-adding activities. This includes optimizing workflow layouts, reducing inventory holding costs, and implementing just-in-time production strategies. Our focus on continuous improvement has led to significant cost savings and enhanced overall operational efficiency.

Maximizing Long-Term Value and Performance

Investing in Corrosion Protection

While initial costs may be higher, investing in superior corrosion protection significantly reduces long-term expenses. Our double-layer protection system, compliant with GB/T 30790 standards, combines spray coating with a durable topcoat. This approach extends the lifespan of steel plate girders, particularly in harsh environments like marine bridges or industrial facilities. By minimizing maintenance and replacement costs over the structure's lifetime, we provide substantial long-term savings for our clients.

Ensuring Quality Through Rigorous Testing

Comprehensive quality control measures, though an upfront investment, lead to significant cost savings by preventing defects and ensuring structural integrity. Our stringent testing protocols, including non-destructive testing (NDT) and fatigue testing, guarantee that each steel plate girder meets the highest standards of quality and performance. This commitment to quality reduces the risk of costly failures or replacements, providing peace of mind and long-term value to our clients.

Offering Customized Solutions for Specific Environments

Tailoring solutions to specific environmental challenges can lead to substantial cost savings over time. Our experience in extreme environments, such as the Alaska Polar Highway Bridge project, demonstrates our ability to provide customized solutions that withstand harsh conditions. By considering factors like temperature fluctuations, corrosive atmospheres, and seismic activity in our designs, we ensure optimal performance and longevity, ultimately reducing lifecycle costs for our clients.

Conclusion

Reducing costs in steel plate girder manufacturing requires a holistic approach that balances immediate savings with long-term value. At Zhongda Steel, we've successfully implemented strategies that optimize material usage, enhance production efficiency, and maximize product performance. By leveraging advanced technologies, streamlining processes, and focusing on quality and durability, we've achieved significant cost reductions without compromising on the integrity and reliability of our steel plate girders. These cost-effective solutions not only benefit our clients but also contribute to more sustainable and efficient infrastructure development worldwide.

Contact Us

Ready to optimize your steel plate girder project and reduce costs without sacrificing quality? Partner with Zhongda Steel for innovative, efficient, and durable solutions tailored to your specific needs. Our expertise in extreme environment applications, rapid manufacturing techniques, and customized engineering ensures you get the best value for your investment. Contact us today at Ava@zd-steels.com to discover how our steel plate girders can elevate your next construction project while keeping costs in check.