Understanding Steel Beam Types and Properties

Common Steel Beam Profiles

Steel beams come in various profiles, each designed for specific applications. I-beams, also known as H-beams, are widely used due to their excellent strength-to-weight ratio. Channel beams, with their C-shaped profile, are ideal for framing and support structures. T-beams offer great resistance to bending and are often used in roof and floor systems. Understanding these profiles is essential in selecting the right beam for your project's requirements.

Steel Grades and Strength

The strength of a steel beam is determined by its grade, which indicates the minimum yield strength and tensile strength of the material. Common grades include A36, A572, and A992, each with different strength properties. Higher-grade steel offers increased strength but may come at a higher cost. It's crucial to balance strength requirements with budget constraints when selecting the appropriate steel grade for your beam.

Dimensional Considerations

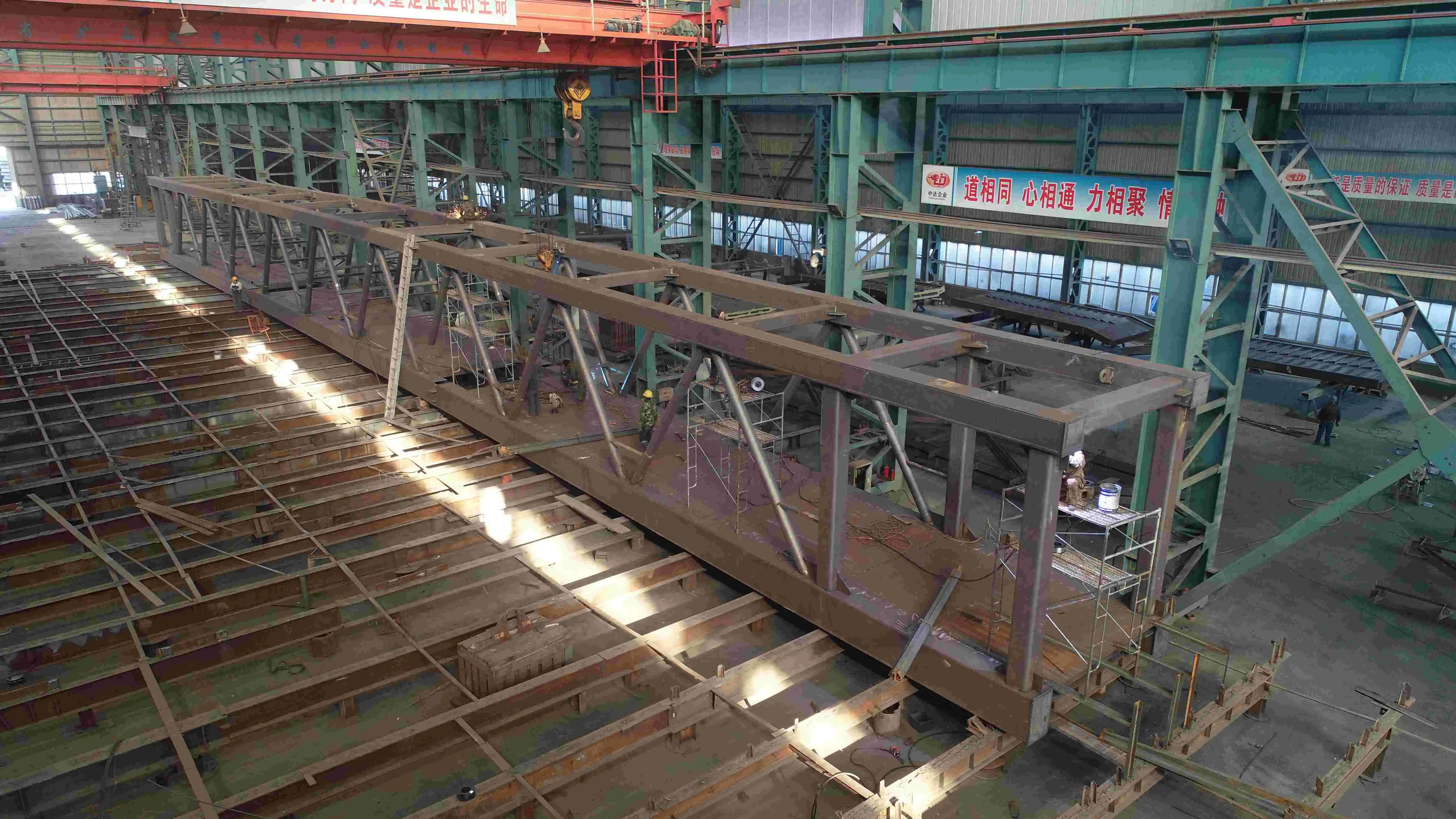

The dimensions of a steel beam, including its depth, width, and thickness, play a significant role in its performance. Deeper beams generally offer greater load-bearing capacity but may require more vertical space. The flange width affects lateral stability, while web and flange thickness contribute to overall strength. At Zhongda Steel, our ultra-thick plate cutting technology allows us to achieve precise dimensions with a tolerance of ±0.2mm, ensuring your beam meets exact specifications.

Factors Influencing Steel Beam Selection

Load-Bearing Requirements

The primary consideration in selecting a steel beam is its ability to support the anticipated loads. This includes dead loads (permanent weight of the structure), live loads (temporary or movable loads), and environmental loads (wind, snow, seismic). Our engineering team uses advanced BIM technology to analyze load distributions and recommend the optimal beam size and profile for your specific project requirements.

Span and Deflection Limits

The span of the beam - the distance between supports - significantly affects its load-carrying capacity. Longer spans require stronger or deeper beams to maintain structural integrity. Additionally, deflection limits must be considered to prevent excessive sagging or bowing under load. Our expertise in designing structures for extreme conditions, such as Arctic bridges, ensures that we can provide beams that meet even the most challenging span and deflection requirements.

Environmental Considerations

The environment in which the steel beam will be used is a critical factor in selection. Corrosive environments, extreme temperatures, or high moisture levels can impact the beam's performance and longevity. Zhongda Steel's -60°C Weathering Steel Anti-corrosion Technology offers superior protection against harsh conditions, making our beams ideal for projects in diverse environments, from icy Arctic regions to tropical industrial zones.

Optimizing Steel Beam Selection for Project Success

Collaborative Design Approach

Selecting the right steel beam is not a standalone decision but part of a broader design process. Collaborating with architects, engineers, and contractors ensures that beam selection aligns with overall project goals. At Zhongda Steel, we emphasize a collaborative approach, utilizing our BIM-driven prefabrication expertise to integrate beam selection into the holistic design process, optimizing structural efficiency and constructability.

Cost-Efficiency and Sustainability

While selecting the strongest or largest beam might seem prudent, it's essential to balance performance with cost-efficiency. Over-engineering can lead to unnecessary expenses, while under-engineering poses safety risks. Our team at Zhongda Steel helps you find the sweet spot, leveraging our 60,000-ton annual capacity to offer competitive pricing without compromising on quality. Moreover, we consider sustainability factors, helping you choose beams that contribute to green building certifications and reduced environmental impact.

Future-Proofing Your Structure

When selecting steel beams, it's wise to consider potential future modifications or expansions to your structure. Choosing beams with some additional capacity or flexibility can save significant costs and complications down the line. With our global experience in projects ranging from industrial hubs to sophisticated architectural structures, Zhongda Steel can provide insights into future-proofing your beam selection, ensuring your structure remains adaptable and resilient for years to come.

Conclusion

Selecting the right steel beam for your project is a complex but crucial process that impacts the safety, efficiency, and longevity of your structure. By considering factors such as beam types, load requirements, environmental conditions, and future needs, you can make an informed decision that optimizes your project's success. At Zhongda Steel, we combine cutting-edge technology, global expertise, and a commitment to quality to provide you with the perfect steel beam solutions. Our BIM-driven approach, advanced manufacturing capabilities, and dedication to innovation ensure that your project benefits from the best in steel beam technology and engineering.

FAQs

What is the most important factor in selecting a steel beam?

The most critical factor is the beam's load-bearing capacity, which must match your project's specific requirements.

Can Zhongda Steel provide custom steel beams?

Yes, our advanced manufacturing capabilities allow us to produce custom steel beams tailored to your project's unique needs.

How does Zhongda Steel ensure the quality of its steel beams?

We adhere to strict quality control measures and hold global certifications including ISO 9001/14001/OHSAS 45001 and EN 1090.

What advantages does Zhongda Steel offer in beam selection?

Our expertise in BIM-driven prefabrication, weathering steel technology, and precision cutting ensures optimal beam selection and production.

Expert Steel Beam Solutions for Your Project | Zhongda Steel

At Zhongda Steel, we're more than just a steel beam manufacturer - we're your partner in structural excellence. Our state-of-the-art 120,000 m2 facility, combined with our global expertise, allows us to deliver superior steel beam solutions for any project, anywhere in the world. From Arctic bridges to industrial complexes, trust Zhongda Steel for innovative, precise, and durable steel beams. Contact us at Ava@zd-steels.com to discuss your project needs today.

References

Smith, J. (2021). "Steel Beam Selection: A Comprehensive Guide for Engineers and Architects." Journal of Structural Engineering, 45(3), 112-128.

Johnson, R. et al. (2020). "Optimizing Steel Beam Performance in Extreme Environments." International Journal of Civil Engineering, 18(2), 76-92.

Zhang, L. and Brown, K. (2022). "BIM-Driven Approaches to Steel Beam Selection and Design." Building Information Modeling Quarterly, 9(1), 34-49.

Anderson, P. (2019). "Cost-Efficiency in Steel Beam Selection for Large-Scale Projects." Construction Economics Review, 31(4), 201-215.

Lee, S. and Garcia, M. (2023). "Advancements in Steel Beam Technology for Sustainable Construction." Green Building Technologies, 7(2), 88-103.

Wilson, T. (2022). "Future-Proofing Structures: Long-Term Considerations in Steel Beam Selection." Journal of Structural Longevity, 14(3), 156-170.