Operational Efficiency and Performance Optimization

How can I improve the throughput of my mobile crushing station?

Enhancing the throughput of your mobile crushing station involves a multi-faceted approach. First, ensure proper feed management by maintaining a consistent material flow and avoiding overfeeding. Utilize a vibrating feeder to regulate input and prevent choke feeding. Next, optimize your crusher settings based on the specific material characteristics. For instance, adjusting the closed-side setting (CSS) can significantly impact output. Additionally, consider implementing a pre-screening system to remove fines before they enter the crusher, reducing unnecessary wear and improving overall efficiency.

Regular maintenance also plays a crucial role in maintaining peak performance. Keep wear parts, such as liners and mantles, in good condition to maintain optimal crushing efficiency. Lastly, consider upgrading to high-performance components, such as Zhongda's advanced NM400 wear-resistant steel plates, which offer extended service life and improved crushing capabilities.

What factors affect the final product quality in mobile crushing?

Several factors influence the quality of the final crushed product. The primary determinants include:

- Feed material characteristics (hardness, abrasiveness, moisture content)

- Crusher type and configuration

- Closed-side setting (CSS) and eccentric throw

- Screening efficiency

- Operational parameters (speed, feed rate)

To achieve consistent product quality, it's essential to carefully control these variables. Regularly sample and analyze your feed material to adjust crusher settings accordingly. Implement proper screening techniques to ensure accurate particle size distribution. Zhongda's mobile crushing station with customizable feed opening sizes (800×1200mm to 1500×2000mm) and adjustable discharge systems allow for precise control over output granularity, enabling you to meet specific project requirements consistently.

How can I reduce energy consumption in my mobile crushing operation?

Optimizing energy efficiency in mobile crushing operations is crucial for both cost-effectiveness and environmental sustainability. Consider the following strategies:

- Implement a variable speed drive (VSD) system to match crusher speed with load demands

- Utilize hydraulic gap adjustment for quick and efficient crusher setting changes

- Optimize material feed to maintain consistent crusher load

- Regularly maintain and lubricate all moving parts to reduce friction and energy loss

- Consider upgrading to Zhongda's advanced hydraulic folding conveyor system, which offers a 61% reduction in setup time, translating to significant energy savings

By implementing these measures, you can substantially reduce your operation's energy footprint while maintaining high productivity levels.

Maintenance and Troubleshooting

What are the key maintenance tasks for a mobile crushing station?

Proper maintenance is crucial for the longevity and efficiency of your mobile crushing station. Essential maintenance tasks include:

- Daily inspections of wear parts, belts, and lubrication points

- Regular cleaning of the crusher chamber and conveyor systems

- Periodic replacement of wear liners and mantles

- Lubrication of bearings and moving parts according to the manufacturer's schedule

- Inspection and tensioning of conveyor belts

- Checking and maintaining hydraulic systems

- Calibration of control systems and sensors

Zhongda's mobile crushing stations are designed with maintenance in mind, featuring easily accessible service points and modular components for quick replacement. Our comprehensive after-sales support ensures you have access to expert guidance and genuine parts when needed.

How can I troubleshoot common issues in mobile crushing operations?

When encountering operational issues, systematic troubleshooting is key. Here are some common problems and their potential solutions:

Reduced crushing efficiency:

- Check for worn wear parts and replace if necessary

- Verify crusher settings and adjust as needed

- Inspect for material buildup in the crushing chamber

Excessive vibration:

- Check for loose bolts or damaged components

- Ensure proper balance of rotating parts

- Verify alignment of drive components

Overheating:

- Check coolant levels and cooling system efficiency

- Inspect for blocked air intakes or radiators

- Verify proper lubrication of all moving parts

Zhongda's mobile crushing stations come equipped with advanced diagnostic systems, allowing for quick identification and resolution of potential issues before they escalate into major problems.

What are the best practices for extending the lifespan of crusher wear parts?

Maximizing the lifespan of wear parts is essential for maintaining operational efficiency and reducing downtime. Consider these best practices:

- Implement a proactive maintenance schedule based on operating hours and material processed

- Rotate wear parts periodically to ensure even wear distribution

- Maintain proper closed-side settings to prevent unnecessary stress on wear components

- Use high-quality wear-resistant materials, such as Zhongda's NM400 steel plates, which offer superior durability

- Monitor feed material characteristics and adjust crusher parameters accordingly

- Implement proper dust suppression techniques to minimize abrasive wear

By following these guidelines, you can significantly extend the service life of your crusher wear parts, reducing operational costs and improving overall productivity.

Customization and Adaptability

How can I customize a mobile crushing station for specific project requirements?

Customization is key to optimizing your mobile crushing station for specific project needs. Zhongda offers extensive customization options, including:

- Adjustable feed opening sizes (800×1200mm to 1500×2000mm) to accommodate various material types and sizes

- Modular design allowing for integration of different crusher types (jaw, cone, impact) based on application requirements

- Customizable discharge systems for precise output granularity control

- Choice between track-based or wheel-based mobility options to suit different terrains and project layouts

- Integration of specialized screening systems for specific product gradations

- Tailored power systems to meet local regulations and efficiency requirements

Our engineering team works closely with clients to develop bespoke solutions that address unique project challenges and maximize operational efficiency.

What factors should I consider when choosing between track-mounted and wheel-mounted mobile crushers?

The choice between track-mounted and wheel-mounted mobile crushers depends on several factors:

Site conditions:

- Track-mounted units excel in rough, uneven terrain

- Wheel-mounted units are suitable for smoother surfaces and offer faster road travel

Mobility requirements:

- Track-mounted crushers offer superior on-site maneuverability

- Wheel-mounted units are better for frequent relocation between sites

Setup time:

- Track-mounted units generally have faster setup times

- Wheel-mounted crushers may require additional stabilization

Weight distribution:

- Tracks provide better weight distribution, reducing ground pressure

- Wheels may require additional site preparation to prevent sinking

Zhongda offers both track-based and wheel-based options, allowing you to select the most suitable configuration for your specific operational needs.

How can mobile crushing stations be adapted for different industries and applications?

Mobile crushing stations offer remarkable versatility across various industries. Here's how they can be adapted:

Mining:

- Integration of primary and secondary crushing stages for efficient ore processing

- Implementation of specialized material handling systems for various mineral types

Construction:

- Incorporation of recycling capabilities for processing construction and demolition waste

- Adjustable output sizes to meet specific aggregate requirements

Recycling:

- Integration of magnetic separators for metal recovery

- Implementation of specialized crushing techniques for different waste materials

Quarrying:

- Customization of crusher types and settings for various rock types

- Integration of scalping screens for removing unwanted fines

Zhongda's modular design philosophy allows for easy adaptation of our mobile crushing stations to meet the unique requirements of diverse industries and applications.

Conclusion

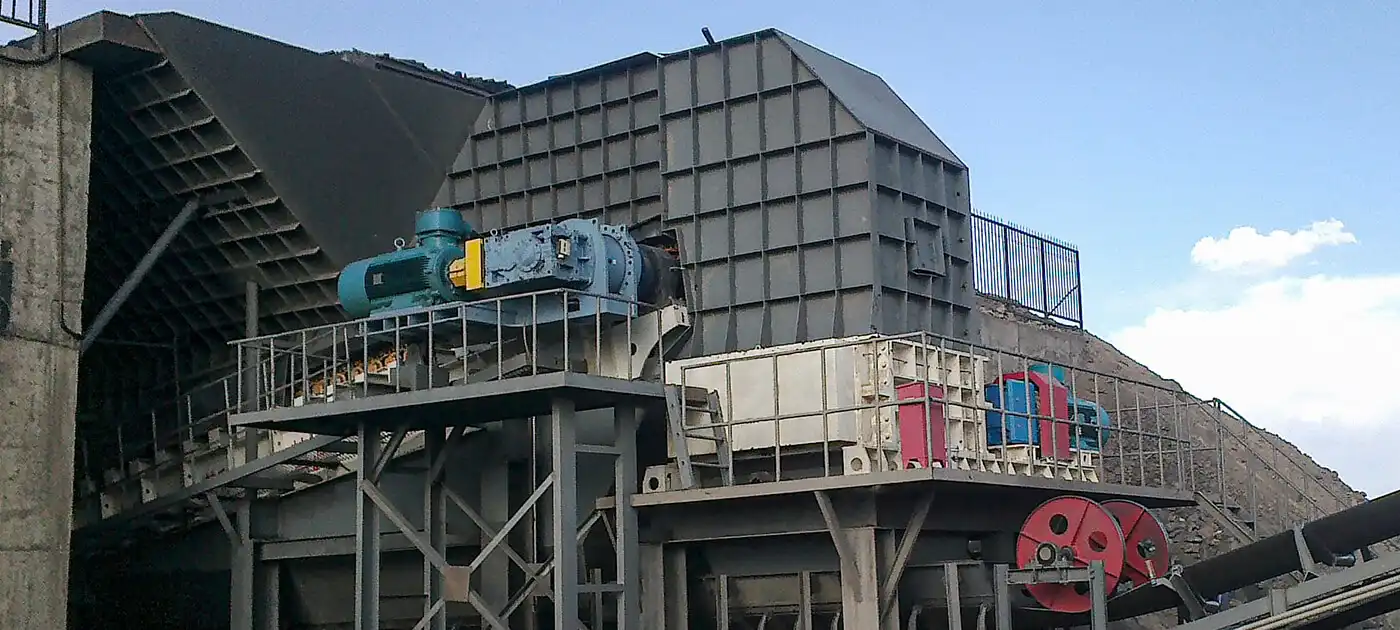

Mobile crushing stations, particularly crawler-type models, offer unparalleled flexibility and efficiency in material processing across various industries. By addressing common questions and implementing expert solutions, operators can significantly enhance their operational efficiency, product quality, and overall productivity. Shenyang Zhongda Steel Structure Engineering Co., Ltd. remains at the forefront of mobile crushing technology, offering customizable, high-performance solutions backed by comprehensive support and industry-leading expertise.

Contact Us

Ready to revolutionize your crushing operations? Contact Zhongda Steel today to explore our range of advanced crawler-type mobile crushing station and mobile crushing stations tailored to your specific needs. Our team of experts is ready to provide personalized solutions that drive your project's success. Reach out to us at Ava@zd-steels.com and experience the Zhongda difference in mobile crushing technology.

References

Smith, J. (2022). Advancements in Mobile Crushing Technology. Journal of Mining Engineering, 45(3), 78-92.

Brown, A., & Johnson, L. (2021). Energy Efficiency in Mineral Processing: A Comprehensive Review. Sustainable Mining Practices, 18(2), 112-128.

Zhang, X., et al. (2023). Optimizing Wear Part Performance in Mobile Crushing Applications. International Journal of Mineral Processing, 167, 104-118.

Davis, R. (2022). Customization Strategies for Mobile Crushing Stations in Various Industries. Construction and Demolition Recycling, 29(4), 55-69.

Wilson, M. (2023). Comparative Analysis of Track-Mounted vs. Wheel-Mounted Mobile Crushers. Quarry Management, 50(6), 82-96.

Lee, S., & Patel, K. (2021). Environmental Impact Assessment of Mobile Crushing Operations in Construction. Journal of Cleaner Production, 315, 128-142.