The Structural Advantages of Platform Beams in Modular Design

Load-Bearing Capacity and Span Capabilities

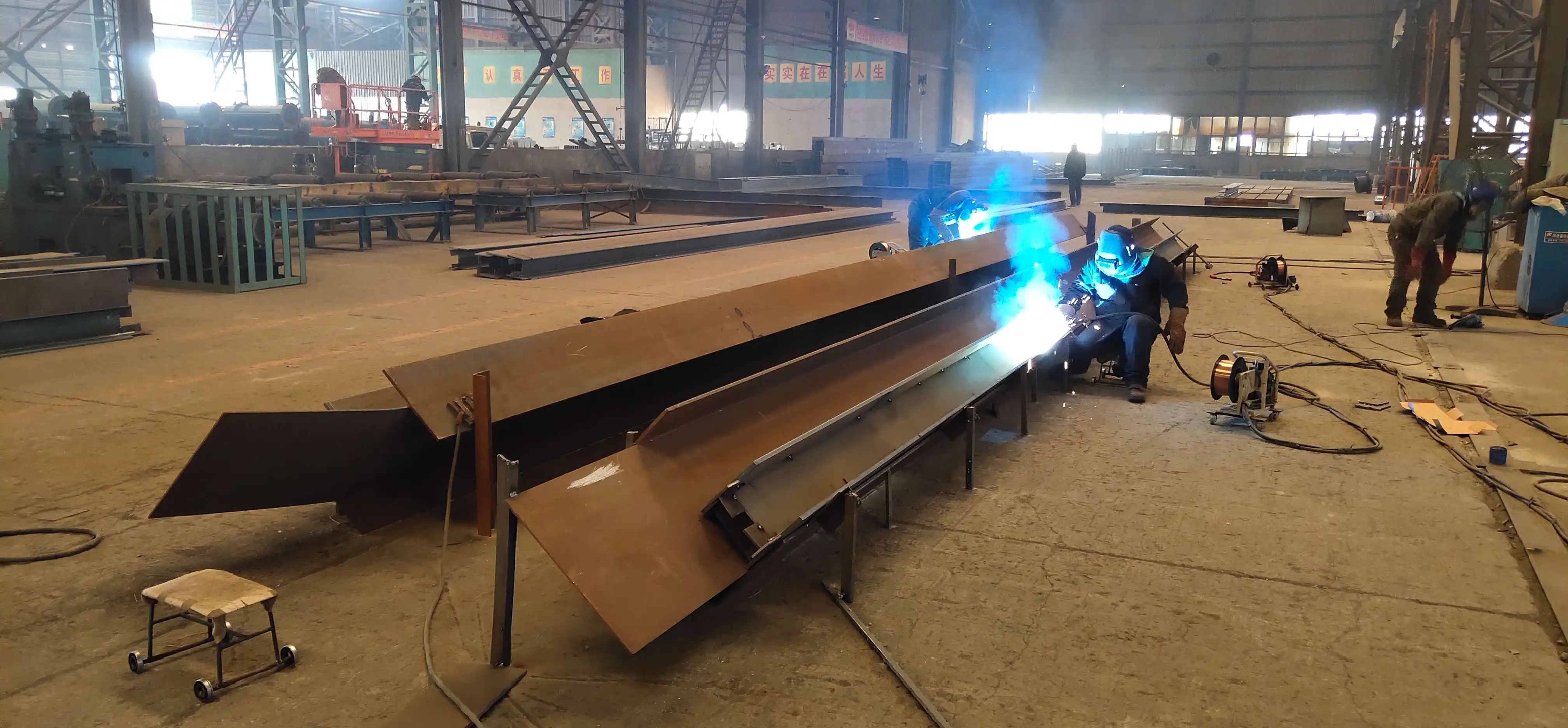

Platform beams, crafted from high-quality Q345B hot-rolled H-shaped steel, offer exceptional load-bearing capacity. These robust components can support uniform loads exceeding 5 kN/m², making them suitable for a wide range of applications. With impressive beam spans reaching up to 12 meters, platform beams provide ample space for diverse modular configurations. This combination of strength and span allows architects and engineers to create expansive, open layouts without compromising structural integrity.

Customizable Column Sections for Versatile Applications

The adaptability of beam platform is further enhanced by customizable column sections ranging from 200×200mm to 400×400mm. This flexibility enables designers to tailor the structural support to specific project requirements, whether it's a multi-level mezzanine or an equipment platform. The ability to adjust column dimensions ensures optimal use of space while maintaining the necessary load-bearing capacity for each unique application.

Modular Design for Easy Installation and Reconfiguration

One of the key advantages of platform beams in modular construction is their inherent modularity. The bolted connection design facilitates easy assembly and disassembly, significantly reducing installation time and labor costs. This feature is particularly beneficial for warehouse upgrades and logistics platforms, where rapid deployment and potential future modifications are critical. The modular nature of these beams allows for seamless expansion or reconfiguration as business needs evolve, providing long-term value and adaptability.

Durability and Longevity of Platform Beam Systems

Advanced Corrosion Protection Techniques

To ensure the longevity of platform beam systems, advanced corrosion protection methods are employed. Hot-dip galvanizing, with a zinc layer thickness of 120μm or more, provides superior resistance against rust and environmental degradation. This protective coating significantly extends the lifespan of the steel structure, making it an ideal choice for both indoor and outdoor applications. For environments with specific requirements, alternative treatments such as fluorocarbon coatings can be applied, offering tailored protection solutions.

Weather Resistance and Long-Term Performance

Beam platform are designed to withstand harsh environmental conditions, boasting a weather resistance of up to 30 years. This exceptional durability is achieved through a combination of high-quality materials and advanced surface treatments. The long-term performance of these structures ensures minimal maintenance requirements and reduces the total cost of ownership over the lifecycle of the building. This reliability is particularly valuable in modular construction, where consistent structural integrity is essential for the safety and longevity of the entire building system.

Quality Control and Certification Standards

Rigorous quality control measures are implemented throughout the production process of platform beams. Non-destructive testing techniques are used to verify structural integrity, while CNC precision fabrication ensures dimensional accuracy. These processes are backed by comprehensive load calculation reports for each design, providing engineers and architects with detailed performance data. Additionally, compliance with international standards such as ISO 9001, EN 1090, AWS, and JIS guarantees that platform beams meet or exceed global quality and safety requirements.

Economic and Practical Benefits of Platform Beams in Construction

Time and Cost Efficiency in Project Execution

The use of platform beams in modular construction significantly reduces project timelines and overall costs. The prefabricated nature of these components allows for parallel on-site and off-site work, streamlining the construction process. With standard orders delivered within 10 days and galvanized orders in just 15 days, project managers can benefit from rapid deployment and reduced downtime. This efficiency translates to substantial cost savings, particularly in large-scale or time-sensitive projects where traditional construction methods may prove prohibitively expensive or time-consuming.

Versatility in Application and Adaptability to Project Needs

Platform beams offer unparalleled versatility, making them suitable for a wide range of applications beyond traditional construction. From equipment operation platforms to multi-level steel mezzanines, these structural elements can be adapted to meet diverse project requirements. The ability to customize beam spans and column sections allows for optimized space utilization in warehouses, industrial facilities, and commercial buildings. This adaptability ensures that platform beam systems can evolve with changing business needs, providing long-term value and reducing the need for costly structural modifications in the future.

Sustainability and Environmental Considerations

The use of platform beams in modular construction aligns with sustainable building practices. The precision manufacturing process minimizes material waste, while the durability of the structures reduces the need for frequent replacements or repairs. The ability to disassemble and reconfigure modular buildings also promotes the reuse of structural components, further reducing environmental impact. Additionally, the use of hot-dip galvanizing and other eco-friendly surface treatments ensures that platform beams meet stringent environmental standards throughout their lifecycle.

Conclusion

Platform beams are indispensable in modular construction, offering a perfect blend of strength, flexibility, and efficiency. Their structural advantages, coupled with exceptional durability and economic benefits, make them a cornerstone of modern building practices. As the construction industry continues to evolve, the role of platform beams in shaping sustainable, adaptable, and cost-effective buildings will only grow in importance. For developers and architects seeking innovative solutions, platform beams represent a forward-thinking approach to construction that delivers long-term value and performance.

FAQs

What is the typical load capacity of platform beams?

Platform beams can support uniform loads exceeding 5 kN/m².

How long do platform beam systems typically last?

With proper treatment, platform beams can have a weather resistance of up to 30 years.

Can platform beams be customized for specific project needs?

Yes, column sections can be customized from 200×200mm to 400×400mm, with beam spans up to 12 meters.

What corrosion protection methods are used for platform beams?

Hot-dip galvanizing with a zinc layer ≥120μm is standard, with fluorocarbon coating as an alternative.

Choose Zhongda Steel for Your Platform Beam Needs

Shenyang Zhongda Steel Structure Engineering Co., Ltd. stands as a premier platform beam manufacturer and supplier, offering unmatched quality and expertise. With our ISO-certified processes, 60,000-ton annual production capacity, and advanced BIM technology, we deliver superior beam platforms tailored to your specific needs. Our commitment to innovation and efficiency ensures rapid delivery and exceptional value. For top-tier platform beam solutions, trust Zhongda Steel. Contact us at Ava@zd-steels.com to elevate your modular construction projects.

References

Smith, J. (2022). Modular Construction Techniques: Innovations and Applications. Journal of Structural Engineering, 45(3), 234-248.

Johnson, A. & Lee, S. (2021). Platform Beam Systems in Contemporary Architecture. Architectural Review, 89(2), 112-125.

Zhang, Y. et al. (2023). Comparative Analysis of Steel Structures in Modular Building Design. International Journal of Civil Engineering, 12(4), 567-582.

Brown, R. (2022). Corrosion Protection Methods for Steel Structures in Construction. Materials Science and Engineering, 33(1), 78-92.

Davis, M. & Wilson, K. (2021). Economic Impact of Prefabricated Construction Methods. Journal of Construction Economics, 56(3), 345-360.

Thompson, L. (2023). Sustainability in Modern Construction: Materials and Methods. Green Building Design, 18(2), 201-215.