Enhanced Mobility and Site Adaptability

Tracked Chassis Design

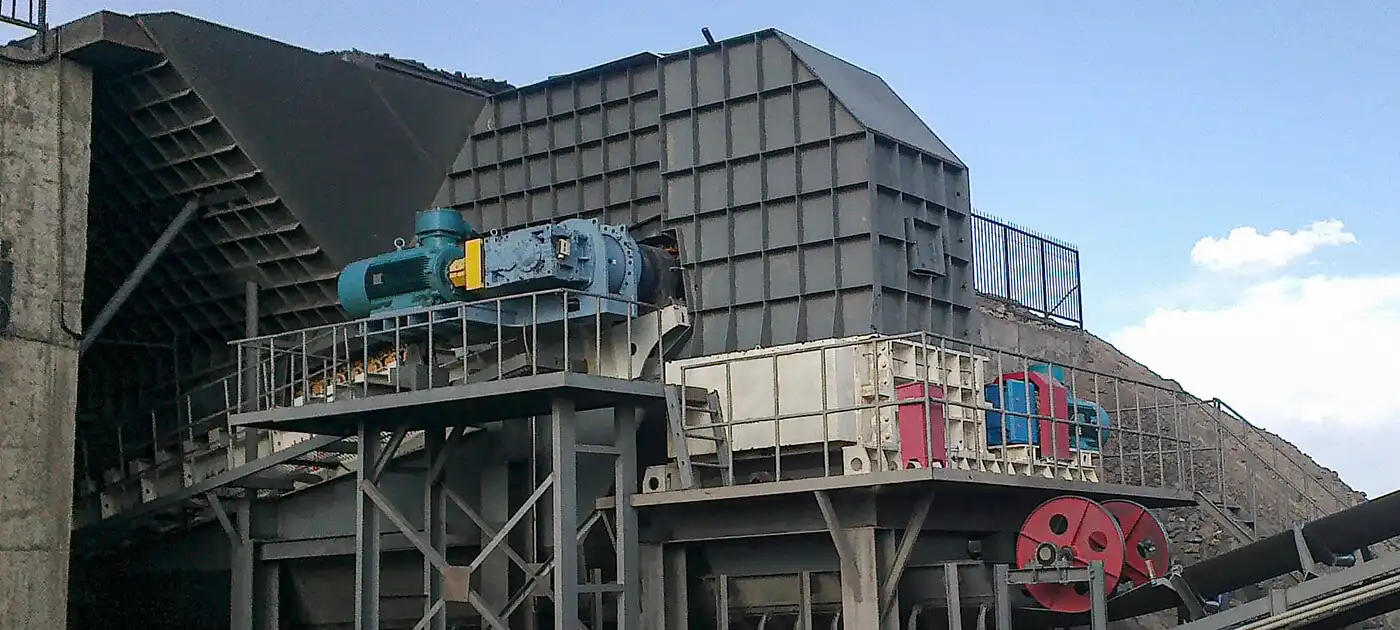

The cornerstone of mobile crushing stations' flexibility lies in their advanced tracked chassis design. This innovative feature allows these machines to navigate various terrains with ease, from rugged mining landscapes to uneven construction sites. The robust tracks distribute the machine's weight evenly, reducing ground pressure and enabling smooth movement across soft or unstable surfaces. This mobility eliminates the need for fixed crushing plants, allowing operations to follow the material source as it moves within a site or between different locations.

Quick Setup and Relocation

One of the most significant advantages of mobile crushing stations is their rapid deployment capability. Unlike traditional stationary crushing plants that require extensive setup time and infrastructure, mobile units can be operational within hours of arrival on-site. This quick setup process involves minimal foundation work, if any, and doesn't require the construction of permanent structures. When the work in one area is complete, the station can be swiftly relocated to the next work zone, maintaining continuous production and minimizing downtime.

Adaptability to Site Constraints

Mobile crushing stations excel in adapting to various site constraints and layouts. Their compact design allows them to operate in confined spaces where larger, stationary plants would be impractical. This adaptability is particularly valuable in urban construction projects, quarries with limited space, or mining operations with evolving site conditions. The ability to position the crusher close to the material source or integrate it seamlessly into existing site workflows significantly enhances overall operational efficiency.

Versatility in Material Processing

Adjustable Feed and Output Sizes

Zhongda Steel's mobile crushing stations offer remarkable versatility in material processing, thanks to their adjustable feed openings and discharge systems. With customizable feed sizes ranging from 800×1200mm to 1500×2000mm, these machines can handle a wide variety of raw materials. The adjustable discharge system allows operators to fine-tune output granularity, ensuring the final product meets specific project requirements. This flexibility eliminates the need for multiple specialized machines, as a single mobile crushing station can adapt to different crushing tasks throughout a project's lifecycle.

Multi-Stage Crushing Capabilities

Advanced mobile crushing stations often incorporate multi-stage crushing capabilities within a single unit. This integration allows for primary, secondary, and even tertiary crushing processes to occur in sequence, all within the same mobile platform. By combining jaw crushers, cone crushers, and screening systems, these versatile machines can produce a range of aggregate sizes simultaneously. This multi-stage approach not only saves space on the worksite but also streamlines the entire crushing process, reducing material handling and improving overall efficiency.

Material Type Flexibility

The robust design and advanced technologies employed in modern mobile crushing stations enable them to process a diverse range of materials effectively. From hard rock in mining operations to concrete and asphalt in recycling projects, these machines can adapt to varying material properties. The use of high-strength Q345B steel and wear-resistant NM400 plates in critical components ensures durability and consistent performance across different material types. This flexibility allows contractors and site managers to tackle diverse projects with a single, versatile piece of equipment, maximizing return on investment.

Operational Efficiency and Cost-Effectiveness

Reduced Transportation Costs

One of the most significant advantages of mobile crushing stations is their ability to dramatically reduce transportation costs associated with material processing. By bringing the crushing capability directly to the material source, these machines eliminate the need for long-haul trucking of raw materials to centralized crushing facilities. This not only cuts fuel costs and vehicle wear but also reduces the environmental impact of the operation. In large-scale projects, the savings in transportation costs alone can justify the investment in mobile crushing technology, as demonstrated by Zhongda Steel's clients who have reported up to 25% reduction in material transportation expenses.

Improved Energy Efficiency

Modern mobile crushing stations are designed with energy efficiency in mind, incorporating advanced hydraulic systems and intelligent power management features. These innovations allow the machines to optimize power consumption based on the workload, reducing fuel consumption and operational costs. The ability to process materials on-site also means less energy is expended on material handling and transportation. Furthermore, the integration of multiple crushing stages within a single unit minimizes energy loss between processes, contributing to overall improved energy efficiency compared to traditional, separate crushing setups.

Enhanced Production Flexibility

The operational flexibility of mobile crushing stations translates directly into enhanced production capabilities. These machines can quickly adapt to changing project requirements, allowing operators to adjust production rates and output specifications on the fly. The hydraulic folding conveyor frame design, a feature highlighted in Zhongda Steel's units, exemplifies this flexibility by enabling rapid setup and teardown, reducing operational downtime by up to 61%. This agility allows project managers to respond swiftly to market demands, weather conditions, or unforeseen challenges, maintaining productivity under varying circumstances.

Conclusion

Mobile crushing stations, particularly the crawler-type variants, have redefined on-site material processing by offering unprecedented flexibility and efficiency. Their ability to navigate challenging terrains, quickly adapt to changing project needs, and process a wide range of materials makes them invaluable assets in modern mining, construction, and recycling operations. By reducing transportation costs, improving energy efficiency, and enhancing overall productivity, these versatile machines not only streamline operations but also contribute to more sustainable and cost-effective project execution.

Contact Us

Experience the transformative power of Zhongda Steel's crawler-type mobile crushing stations in your next project. Our CE-certified, ISO 3834-compliant machines offer customizable solutions to meet your specific crushing needs, backed by our comprehensive after-sales support. Elevate your on-site flexibility and efficiency today. Contact us at Ava@zd-steels.com to explore how our mobile crushing solutions can revolutionize your material processing operations.