The quality of the materials used, the weather and climate, the building techniques, and the upkeep of the bridge are all linked and affect how long a steel truss bridge lasts. Procurement managers and engineers can make smart choices that will keep the structure standing for as long as possible, save money, and make sure the bridge works well for its entire life if they know these factors. This all-inclusive guide goes over important things that affect how long bridges last and gives useful information to building experts who want to get the most out of their investments.

Understanding the Lifespan of Steel Truss Bridges

Bridge buildings are big investments in infrastructure that must provide dependable service for decades, even when conditions are difficult. The expected operating time changes a lot depending on different things that affect how well the structure works and stays intact.

Typical Service Life Expectations

If all goes well, modern steel truss bridges usually stay in good enough shape for 75 to 120 years. But real speed changes a lot depending on the conditions, the amount of traffic, and how well it's maintained. When properly built and kept, Warren and Pratt truss configurations show great longevity. These configurations are widely used for spans between 30 and 150 meters. Today's bridge systems are flexible, which means that parts can be replaced and added that can make the bridge last longer than expected.

Structural Definition and Applications

These built-on-purpose buildings use triangular frames to spread out the weight on their long parts. Heavy-duty designs that can handle dynamic loading, wear resistance, and exposure to the elements are needed for highway uses with load limits of up to 100 tons. Railway uses have more problems, like dealing with shaking and needing more dead weight, which affect estimates of how long the system will last.

Primary Factors Affecting Steel Truss Bridge Durability

The long-term performance of a steel truss bridge depends on the materials that are used. For example, how well the bridge resists rust and how much weight it can hold depend on the type of steel that is used.

Material Quality and Steel Grade Selection

Compared to normal construction grades, high-performance steels like ASTM A709 Grade 50 have better strength and longevity. Lamellar tearing is a big issue for heavy-duty uses that have to deal with stress patterns from more than one way. Z35 Z-direction features help avoid this problem. Weathering steel made with newer formulas has built-in rust protection that lowers the need for upkeep and extends the material's lifespan.

Design Elements and Load Distribution

The right shape for your truss will help evenly spread the stress across the whole structure. This will keep tiredness from building up in one area. The long-term performance is greatly affected by joint design and connection details. When forces are spread out evenly across various load lines, it means that the connections are designed correctly. Design features that are seismic-resistant protect the building from dynamic loading events that could make the structure unsafe.

Environmental Exposure Considerations

Different weather conditions affect the rate at which materials break down by changing the way they corrode. The changes in temperature, moisture, and pollution in the air speed up rust, which lowers the load capacity and useful cross-sections. Coastal sites face more problems because of exposure to salt spray, which needs better security plans.

Construction and Maintenance: Key to Lifespan Extension

The way of construction has a big impact on both the quality of the work when it is first done and how well it performs over time. When compared to field assembly in situations that can change, controlled production settings usually get better results.

Prefabrication Advantages

Modern prefabrication methods make sure that quality control and precise building are always done right, which makes the structure work better. Before shipping, controlled working conditions allow for the best welding settings, precise size control, and full quality checks. The ability to quickly come together reduces the time needed for field installation while keeping high standards of building. With our flexible design method, we can customize the truss type, span length, and load capacity to fit the needs of each project.

Quality Control and Inspection Protocols

Before they weaken the strength of the structure, thorough checking methods that use Magnetic Particle Testing (MT) and Ultrasonic Testing (UT) can find possible flaws. Full-node checking procedures make sure that all of the important connections meet the required quality standards. These tough tests and the ISO 9001 approval standards make sure that the quality of the steel truss bridges is always high, which helps meet goals for longer service lives.

Maintenance Strategy Implementation

Preventive maintenance programs greatly extend the useful life of things by fixing small problems before they turn into big structural issues. Regular checks find the beginning of rust, the breaking of connections, and the growth of stress cracks. These issues need to be fixed right away. Renewing the protective covering, taking care of the joints, and swapping out parts all help the structure keep its strength over the course of the design life.

Comparative Insights: Steel Truss Bridges vs Other Bridge Types

Procurement pros need to know how different kinds of bridges perform so they can pick the best ones for certain jobs and needs.

Performance Comparison Analysis

When compared to concrete options, steel truss systems have better load-to-weight ratios. This allows for longer lengths with fewer needs for a base. The maintenance ease benefits that make it easier to check and fix things quickly, which makes them last longer. Even though concrete bridges might need less regular upkeep, steel ones are easier to modify for more capacity and change parts while they are in use.

Economic Lifecycle Considerations

Initial building speed benefits lower the time and cost of a job. Steel truss bridge systems use modular components that allow phased construction, significantly reducing traffic disruption during installation. Emergency applications benefit from rapid deployment, with demountable steel truss bridge structures capable of spanning up to 200 meters in just 50 hours when immediate access restoration is required.

Procurement Considerations for Maximizing Steel Truss Bridge Lifespan

Choosing makers with proven knowledge and skills guarantees the success of the project and the stability of the performance over time. Technical skill, quality systems, and support services after installation should all be part of the broad evaluation standards.

Manufacturer Selection Criteria

Meeting ISO 9001, 14001, and 45001 standards is one way to show that you are committed to environmental duty and quality management. Class I Steel Structure Contracting Qualifications show that you have the right skills to work on difficult tasks. Following international standards like EN 1090, AWS, and JIS makes sure that the work can meet both global project needs and rules.

Here are the important buying benefits that set the best makers apart:

- With an annual production capacity of 60,000 tons, various jobs can be the same time, on time, and with the right quality.

- The advanced workshop with a 50-ton crane that can handle big materials makes sure that the production process has exact assembly and quality control.

- Vertically integrating the skills of research and development through building delivery allows all stages of the project to work together and take responsibility.

- Working together with top universities and design schools on projects helps bring about new products and tech solutions.

All of these make project risk lower while making sure that infrastructure investments work as well as possible and last a long time.

Advanced Protection Systems

Anti-corrosion technology is very important for extending the operating life of something. Using epoxy mica as an intermediate layer, polyurethane as a finish, and 160-micrometer zinc thermal spray, advanced protection systems fully shield surfaces from damage in any setting. This multi-layer method protects against rust in the long term and doesn't need to be fixed as much while it's in service.

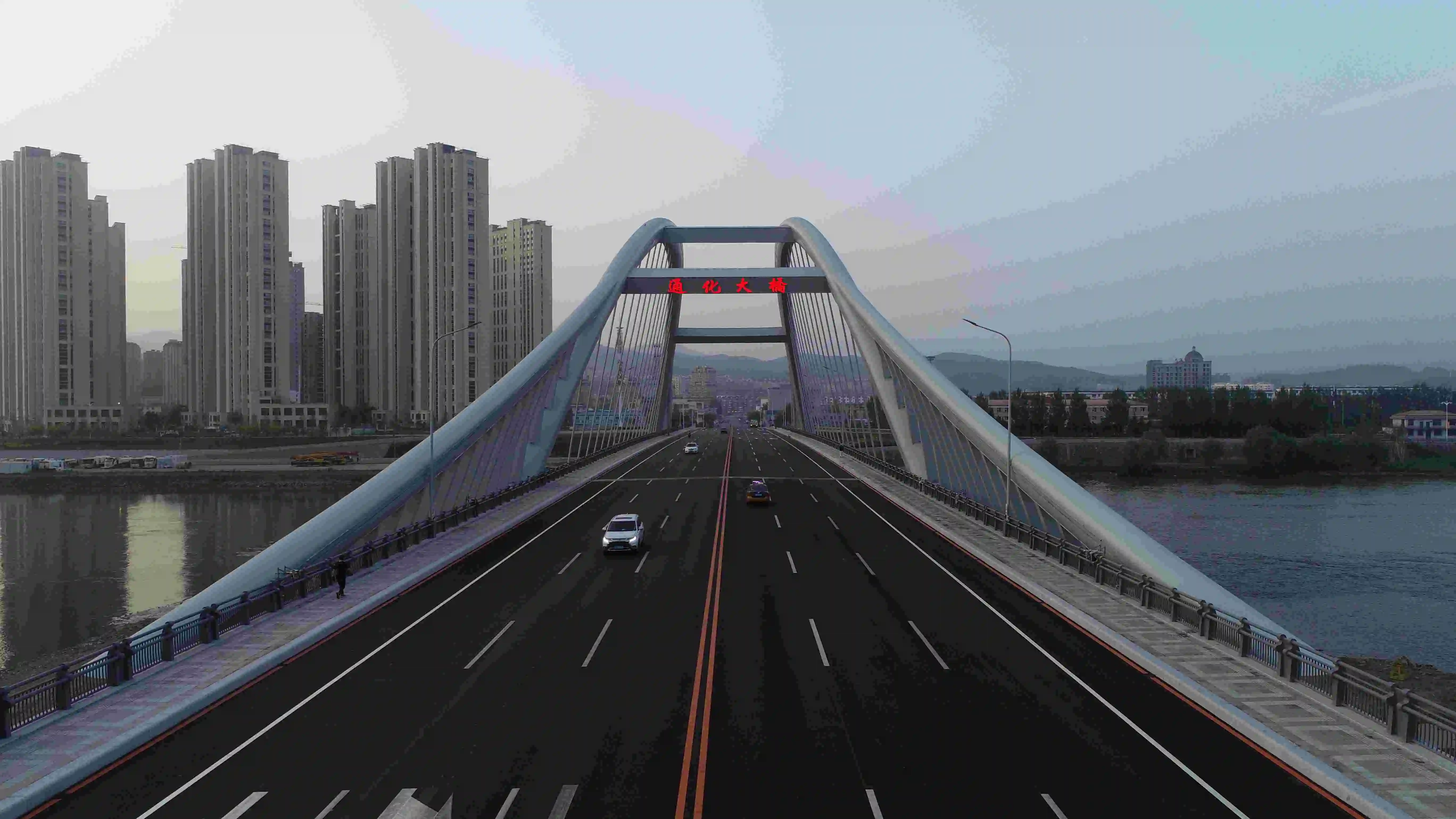

Zhongda Steel Structure Engineering: Your Trusted Steel Truss Bridge Manufacturer

Shenyang Zhongda Steel Structure Engineering Co., Ltd. uses twenty years of experience around the world in making and providing complete steel truss bridge solutions that focus on approved construction and engineering quality. Our all-inclusive method includes help with design, exact making, and custom upkeep plans that are meant to make the structure last longer and be more environmentally friendly.

Our proven track record includes over 60 major projects, such as the 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge and several major infrastructure projects for China Railway, CSCEC, and CCCC. We are committed to client happiness and business efficiency. This is shown by our 70% client renewal rate and wait time that is 20-30% shorter than the industry average.

We are dedicated to quality and working with our clients. We make sure that every project meets strict global guidelines while also helping to make long-term infrastructure investment success. Thanks to BIM-driven prefabrication, cutting plates with ±0.2mm precision, and using advanced anti-corrosion technology, we can offer amazing quality that stands up to harsh settings from the Arctic to the tropics.

Conclusion

A steel truss bridge can last a long time if the materials are carefully chosen, the design is made as simple as possible, the bridge is built well, and the plan for keeping it in good shape is put into action. Procurement experts can choose bridges that provide great value for the length of their working life if they understand these linked parts. Using new materials, well-tested ways of making things, and thorough quality control methods together make sure that structures are reliable and perform better than they usually would. Making strategic partners with experienced makers can give you access to new technologies and support services that will help your infrastructure investments pay off and lower your long-term business risks.

FAQs

To make sure steel truss bridges last as long as possible, how often should they be checked?

In normal situations, thorough checks should happen every 2 to 3 years. After major weather events or earthquakes, more detailed exams should be done. Every year, routine eye checks may be done to find problems that need to be fixed right away.

What ways of taking care of steel truss bridges keep them from getting rusty?

Effective rust protection includes cleaning regularly to get rid of things that don't belong, reapplying protective coating on a regular basis, and fixing areas that are damaged right away. When properly kept throughout the service life, advanced multi-layer finishing methods offer better security.

Can pre-made parts for steel truss bridges change how long the bridge lasts?

Typically, prefabrication makes things more durable by making them in controlled conditions that guarantee consistent quality, exact size, and the best welding conditions. This method is usually better in the long run than options that are put together in the field.

Partner with Zhongda for Superior Steel Truss Bridge Solutions

Get the most out of your building projects and help them last longer with Zhongda's all-around steel truss bridge options. We offer great value for tough uses because we know a lot about flexible Warren and Pratt truss systems and use high-tech ASTM A709 Grade 50 materials and multi-layer anti-corrosion protection. We are a top steel truss bridge provider, and our quality systems are approved by ISO. We also have a proven track record of getting projects done. We offer personalized solutions that meet your exact business needs while beating performance standards. Our emergency response skills and quick building methods make sure that projects succeed even when there isn't a lot of time to do them. To talk about your project's needs and see how our technical knowledge can help you get the most out of your infrastructure investment, email us at Ava@zd-steels.com.

References

American Association of State Highway and Transportation Officials. "AASHTO LRFD Bridge Design Specifications: Steel Bridge Design and Construction Standards." 8th Edition, 2017.

Fisher, John W., and Roy, Sougata. "Fatigue and Fracture in Steel Bridges: Case Studies, Failure Analysis, and Solutions." John Wiley & Sons Engineering Publications, 2019.

Kulicki, John M., et al. "Guidelines for Design of Cable-Stayed and Suspension Bridges." Transportation Research Board National Cooperative Highway Research Program, 2018.

Zhao, Zhenyu, and Liu, Hongping. "Corrosion Protection Systems for Steel Bridge Infrastructure: Performance Evaluation and Life Cycle Analysis." Journal of Construction Steel Research, Vol. 165, 2020.

White, Donald W., and Barker, Michael G. "Steel Bridge Design Handbook: Truss Bridges - Design and Construction Guidelines." Federal Highway Administration Office of Bridge Technology, 2019.

Connor, Robert J., and Fisher, John W. "Service Life Prediction and Management of Steel Bridge Infrastructure Systems." Structure and Infrastructure Engineering International Journal, Vol. 16, Issue 3, 2020.